Tungsten Carbide Inserts for VSI Rotor Tips

Zhuzhou Eastern Carbide Co., Ltd.- Certification:ISO 9001:2000, ISO 9001:2008

- Standard:AISI, ASME, BS, ANSI, JIS, GB, GOST, ASTM, DIN

- Surface Treatment:Sand Blast

- Manufacturing Process:Pressing and Sintering

- Material:Tungsten Carbide

- Fixed on:VSI Rotor Tips

Base Info

- Model NO.:Tungsten carbide inserts

- Fit Machines:Barmac, Sandvic, Metso, Liming

- Advantage:Long Tool Life with Our Carbide Parts

- Customized:Available

- Application:Break The Stone, Rock and Ore Blocks

- Transport Package:Wooden Box with Foam Inside

- Specification:W20~25xT8~15xL50~275 mm

- Trademark:Laser mark available

- Origin:Zhuzhou City, Hunan, China

- HS Code:8209009000

- Production Capacity:500000 Pieces

Description

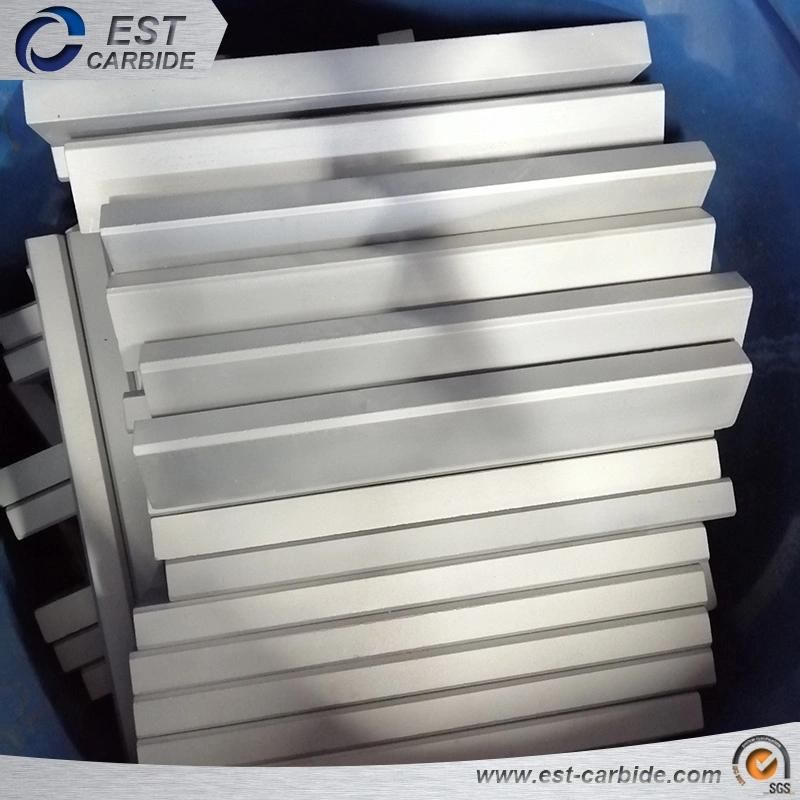

Porduct Photos:

Please note that we are not only make the standard types, but also can make customized parts based on your designs.

Our regular product is tungsten carbide tips, carbide inserts, end mills,carbide saw tips,carbide mining parts, carbide rods, plates and stripes.

We also have rich experience for customized product, we make your designs become real product, which perfectly match your need. We have many successful projects on the for our clients in different countries.

Packing:

A. Standard packing

1).Plastic boxes with foam inside and carton outside.

2).Paper boxes with foam inside and carton outside.

3).Inner boxes/packing material inside and plywood box outside (for heavy product).

B. Customized packing available: We can do special packing based on client's requirements..

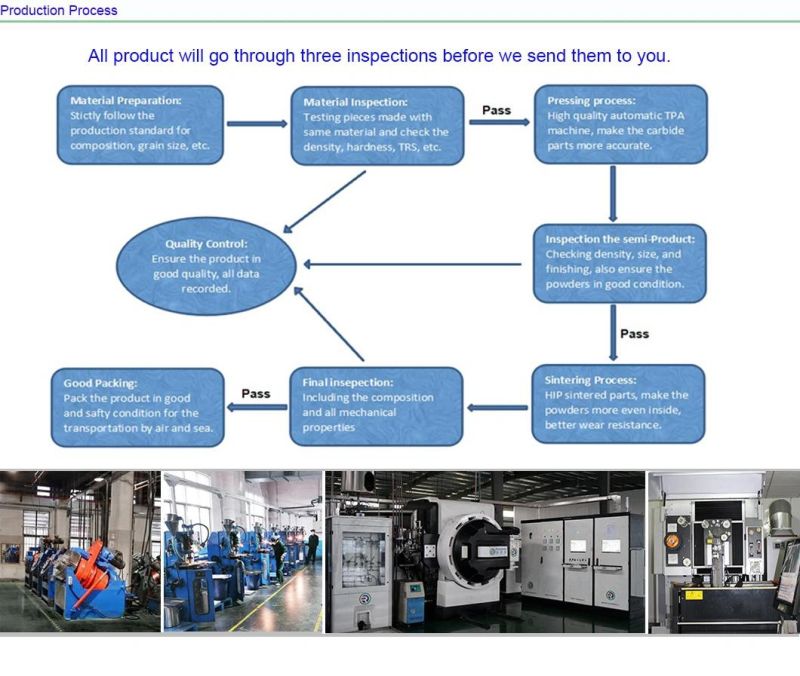

Quality Control System: We always follow the high quality standard for production, from the material preparing to final product ready, all product will go through 3 inspections before we send them to you. Our professional teams will take care of your product and ensure the good and stable quality for all batches.