Mineral Processing Equipment Sand Slurry Pump

Shijiazhuang Naipu Pump Co., Ltd.- Type:Slurry Pump

- Voltage:380V

- Weight:<1T

- Material:High Chrome Alloy

- Material Feature:Abrasive Resistant

- Certification:ISO9001:2008, ISO9001:2000, CE

Base Info

- Model NO.:8,6F-AH

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Multi Color

- Customized:Customized

- Condition:New

- Name1:Slurry Pump

- Name 2:Gravel Sand Pump

- Name 3:Dredging Pump

- Name 4:Sludge Pump

- Size:1 Inch to 18 Inch

- Flow Rate:5-5400m3,H

- Head:5 to 118m

- Main Use:Mining, Power, Coal, Mallurgy Sand Dredging

- Manufacture:Shijiazhuang Naipu Pump Co., Ltd

- Transport Package:Plywood Case

- Specification:CE, ISO, SGS

- Trademark:Naipu

- Origin:Shijiazhuang City

- HS Code:8413709990

- Production Capacity:500 Set

Description

Impeller

Dia.m3/h l/s 6/4D-G 60 36-250 10-70 5-52 600-1400 58 2.5-3.5 378 8/6E-G 120 126-576 35-160 6-45 800-1400 60 3-4.5 378 10/8S-GH 560 216-936 60-260 8-52 500-1000 65 3-7.5 533 10/8S-G 560 180-1440 50-400 24-30 500-950 72 2.5-5 711 12/10G-G 600 360-1440 100-400 10-60 400-850 65 1.5-4.5 667 12/10G-GH 1200 288-2808 80-780 16-80 350-700 73 2.0-10.0 950 14/12G-G 1200 576-3024 160-840 8-70 300-700 68 2.0-8.0 864 16/14TU-GH 1200 324-3600 90-1000 26-70 300-500 72 3.0-6.0 1270 18/16T-G 1200 720-4320 200-1200 12-48 250-500 72 3.0-6.0 1067

Submersible Slurry Sand Pump

ZJQ Performance Parameter NO. Model Outlet mm Flow m3/h Head

m Power kW η (%) Speed r/min Max Solid passing

mm weight kg 1 ZJQ10-20-3 50 10 20 3 37 1460 8 110 2 ZJQ15-18-3 50 15 18 3 46 1460 8 110 3 ZJQ20-15-3 50 20 15 3 52 1460 8 110 4 ZJQ25-12-3 50 25 12 3 58 1460 8 110 5 ZJQ30-12-3 65 30 12 3 60 1460 8 110 6 ZJQ35-10-3 65 35 10 3 64 1460 8 110 7 ZJQ40-8-3 65 40 8 3 66 1460 8 110 8 ZJQ15-22-4 50 15 22 4 43 1460 10 113 9 ZJQ18-20-4 50 18 20 4 46 1460 10 113 10 ZJQ20-18-4 50 20 18 4 50 1460 10 113 11 ZJQ25-20-4 50 25 20 4 52 1460 10 113 12 ZJQ30-16-4 65 30 16 4 52 1460 10 113 13 ZJQ35-15-4 65 35 15 4 60 1460 10 113 14 ZJQ40-12-4 65 40 12 4 63 1460 10 113 15 ZJQ45-10-4 65 45 10 4 66 1460 10 113 16 ZJQ20-30-5.5 80 20 30 5.5 42 1460 13 205 17 ZJQ30-20-5.5 80 30 20 5.5 54 1460 13 205 18 ZJQ45-15-5.5 80 45 15 5.5 41 1460 13 205 19 ZJQ15-20-5.5 80 15 20 5.5 33 1460 13 205 20 ZJQ50-10-5.5 80 50 10 5.5 44 1460 13 205 21 ZJQ15-20-7.5 80 15 20 7.5 34 1460 13 210 22 ZJQ20-25-7.5 80 20 25 7.5 35 1460 13 210 23 ZJQ25-20-7.5 80 25 20 7.5 36 1460 13 210 24 ZJQ25-30-7.5 80 25 30 7.5 36 1460 13 210 25 ZJQ30-30-7.5 80 30 30 7.5 37 1460 13 210 26 ZJQ32-20-7.5 80 32 20 7.5 37 1460 13 210 27 ZJQ45-15-7.5 80 45 15 7.5 41 1460 13 210 28 ZJQ100-10-7.5 100 100 10 7.5 48 1460 21 220 29 ZJQ25-40-11 80 25 40 11 36 1460 13 300 30 ZJQ40-25-11 80 40 25 11 38 1460 13 240 31 ZJQ50-21-11 80 50 21 11 40 1460 13 240 32 ZJQ50-26-11 80 50 26 11 40 1460 13 240 33 ZJQ70-20-11 80 70 20 11 43 1460 13 240 34 ZJQ100-18-11 100 100 18 11 48 1460 21 240 35 ZJQ25-40-15 80 25 40 15 37 1460 13 330 36 ZJQ50-26-15 80 50 26 15 40 1460 13 260 37 ZJQ50-28-15 80 50 28 15 40 1460 13 260 38 ZJQ60-30-15 100 60 30 15 41 1460 13 265 39 ZJQ70-24-15 80 70 24 15 42 1460 13 260 40 ZJQ75-25-15 100 75 25 15 43 1460 13 260 41 ZJQ100-18-15 100 100 18 15 49 1460 21 270 42 ZJQ150-15-15 100 150 15 15 51 1460 21 270 43 ZJQ150-18-18.5 150 150 18 18.5 49 980 32 550 44 ZJQ200-12-18.5 150 200 12 18.5 53 980 45 550 45 ZJQ150-22-22 150 150 22 22 47 980 32 600 46 ZJQ200-15-22 150 200 15 22 50 980 45 600 47 ZJQ60-46-30 150 60 46 30 41 980 14 550 48 ZJQ70-38-30 150 70 38 30 42 980 21 710 49 ZJQ100-35-30 150 100 35 30 44 980 21 710 50 ZJQ108-30-30 150 108 30 30 44 980 21 710 51 ZJQ150-30-30 150 150 30 30 46 980 21 710 52 ZJQ150-35-30 150 150 35 30 46 980 21 710 53 ZJQ200-20-30 150 200 20 30 52 980 21 710 54 ZJQ240-20-30 150 240 20 30 55 980 21 710 55 ZJQ300-15-30 200 300 15 30 56 980 28 700 56 ZJQ100-50-37 150 100 50 37 44 980 21 850 57 ZJQ300-20-37 200 300 20 37 56 980 28 775 58 ZJQ400-15-37 200 400 15 37 58 980 28 775 59 ZJQ150-35-45 150 150 35 45 47 980 36 1000 60 ZJQ200-30-45 150 200 30 45 49 980 36 1110 61 ZJQ500-15-45 200 500 15 45 59 980 46 1100 62 ZJQ150-45-55 150 150 45 55 46 980 21 1140 63 ZJQ250-35-55 150 250 35 55 51 980 36 1140 64 ZJQ600-15-55 200 600 15 55 60 980 46 1220 65 ZJQ200-45-75 150 200 45 75 49 980 21 1540 66 ZJQ200-50-75 150 200 50 75 48 980 14 1550 67 ZJQ350-35-75 200 350 35 75 53 980 28 1550 68 ZJQ400-25-75 200 400 25 75 58 980 25 1550 69 ZJQ500-20-75 200 500 20 75 59 980 25 1550 70 ZJQ200-60-90 150 200 60 90 48 980 14 1550 71 ZJQ400-40-90 200 400 40 90 54 980 28 1550 72 ZJQ500-25-90 200 500 25 90 60 980 25 1550 73 ZJQ400-50-110 200 400 50 110 53 980 28 1970 74 ZJQ600-30-110 200 600 30 110 61 980 28 1970 75 ZJQ780-26-110 300 780 26 110 62 980 50 1970 76 ZJQ1000-18-110 300 1000 18 110 64 980 50 1970 77 ZJQ400-60-132 200 400 60 132 53 980 28 2000 78 ZJQ500-45-132 200 500 45 132 56 980 28 2000 79 ZJQ500-55-132 200 500 55 132 55 980 28 2000 80 ZJQ800-35-132 300 800 35 132 63 980 42 2000 81 ZJQ1000-22-132 300 1000 22 132 64 980 50 2000 82 ZJQ650-52-160 200 650 52 160 58 980 28 2650 83 ZJQ780-50-185 300 780 50 185 60 980 38 3330 84 ZJQ800-55-220 300 800 55 220 60 980 38 3400 85 ZJQ1250-35-220 350 1250 35 220 65 980 45 3400 86 ZJQ1750-30-250 350 1750 30 250 67 980 55 3750 87 ZJQ1500-35-250 350 1500 35 250 66 980 50 3750 88 ZJQ2000-35-315 400 2000 35 315 68 980 60 3800

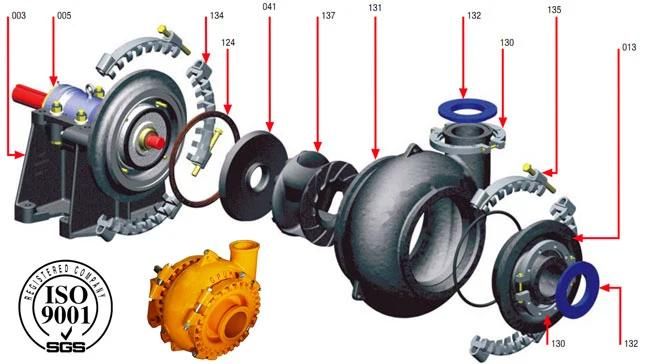

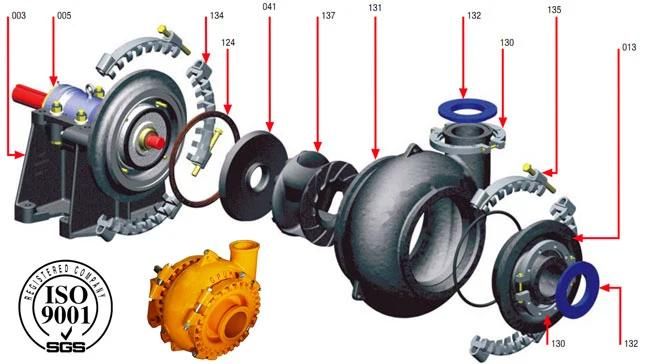

Spare Parts

Impeller, Volute Liner, Casing, ThroatBush, Frame Plate Liner Insert, Cover Plate, Frame Plate, Pump Liner Expeller, Expeller Ring, Stuffing Box, Expeller, Pump Shaft, shaft sleeve, Shaft Spacer, Bearing Assembly, Base, Stuffing Box, Gland Assembly, Bearing Housing, Lantern Ring, pump discharge pipe, flange, and so on.

OEM Service

Based on many years of rich experience in slurry pump manufacturing and design, NAIPU can undertake OEM customization for the whole set of pump and various spare parts. The slurry pump spare parts can be made of various material according to customer's requirement, Such as: Alloy 20, Hastelloy Alloy, A 61 and so on.

Our company undertakes the design, processing and transformation of various special pump parts. According to the user's requirements, Naipu Factory can manufacture various materials and components to meet the needs of different working conditions. Or in accordance with user requirements on the existing equipment technology transformation, combined with our company's rich hydraulic model, through advanced computer simulation technology, to provide users with a complete and effective solution.

WorkShop

Shijiazhuang NaiPu Pump Co., Ltd have own Foundry workshop, Machining Workshop, Assembly workshop, and advanced test equipment.

Welcome to visit our factory!

Inspection

All products are stringently tested to ensure quality and performance

FAQ

1. What Products does naipu pump mainly produce?

Naipu mainly Produce Slurry Pump, Gravel sand Pump, Dredging Pump, Centrifugal water pump and Spare Parts. Not only Pump parts, but also others wear casting parts if there is drawing or sample.

2. Is Naipu direct factory or trader?

Naipu own foundry workshop, Machining Workshop, and Assembly workshop.

The factory is located in ShiJiazhuang City, Hebei , China,covers an area of 30,000m.

Welcome to visit Naipu factory anytime.

3. The Min MQQ

The MQQ is one PCS spare parts.

4. What information is required for quotes?

If you need the spare parts, we need to know the parts Code and material.

If you need the whole pump set, we need to know the usage? The flow, head, and SG, Corrosive or not? The more detailed the better.

Welcome to Contact Me

ShiJiaZhuang NaiPu Pump Co., Ltd

Contact person: Kitty Liu

Shijiazhuang, Headquarters

Add.: No. 368, Xinshi North Road, Shijiazhuang, Hebei Province, China

Dia.

Submersible Slurry Sand Pump

ZJQ Performance Parameter

m

mm

Spare Parts

Impeller, Volute Liner, Casing, ThroatBush, Frame Plate Liner Insert, Cover Plate, Frame Plate, Pump Liner Expeller, Expeller Ring, Stuffing Box, Expeller, Pump Shaft, shaft sleeve, Shaft Spacer, Bearing Assembly, Base, Stuffing Box, Gland Assembly, Bearing Housing, Lantern Ring, pump discharge pipe, flange, and so on.

OEM Service

Based on many years of rich experience in slurry pump manufacturing and design, NAIPU can undertake OEM customization for the whole set of pump and various spare parts. The slurry pump spare parts can be made of various material according to customer's requirement, Such as: Alloy 20, Hastelloy Alloy, A 61 and so on.

Our company undertakes the design, processing and transformation of various special pump parts. According to the user's requirements, Naipu Factory can manufacture various materials and components to meet the needs of different working conditions. Or in accordance with user requirements on the existing equipment technology transformation, combined with our company's rich hydraulic model, through advanced computer simulation technology, to provide users with a complete and effective solution.

Application:

The parts are widely used in Main Applications: Heavy Mining Mineral Processing Sand and Gravel Coal Prep Cyclone Feeds Aggregate Processing Fine Primary Mill Grinding Chemical Slurry Service Tailings Secondary Grinding Industrial Processing Pulp And Paper Food Processing Cracking Operations Ash Handling Pipeline Transport High Velocity Hydraulic Transport Food Processing Explosive Sludge In Metal Smelting River And Pond Dredging Heavy Refuse Removal Larger Particle Or Low NPSHA Applications Continuous (Snore) Sump Pump Operation Abrasive Slurries High Density Slurries Large Particle Slurries Sump Drainage Wash down Floor Drainage Mixing Iron Ore Cooper Diamond Alumina Coal Gold Kaolin Phosphorite Steel Palm Suger Chemical Power FGD Frac Sand Blending Construction City Sewage etc.WorkShop

Shijiazhuang NaiPu Pump Co., Ltd have own Foundry workshop, Machining Workshop, Assembly workshop, and advanced test equipment.

Welcome to visit our factory!

Inspection

All products are stringently tested to ensure quality and performance

FAQ

1. What Products does naipu pump mainly produce?

Naipu mainly Produce Slurry Pump, Gravel sand Pump, Dredging Pump, Centrifugal water pump and Spare Parts. Not only Pump parts, but also others wear casting parts if there is drawing or sample.

2. Is Naipu direct factory or trader?

Naipu own foundry workshop, Machining Workshop, and Assembly workshop.

The factory is located in ShiJiazhuang City, Hebei , China,covers an area of 30,000m.

Welcome to visit Naipu factory anytime.

3. The Min MQQ

The MQQ is one PCS spare parts.

4. What information is required for quotes?

If you need the spare parts, we need to know the parts Code and material.

If you need the whole pump set, we need to know the usage? The flow, head, and SG, Corrosive or not? The more detailed the better.

Welcome to Contact Me

ShiJiaZhuang NaiPu Pump Co., Ltd

Contact person: Kitty Liu

Shijiazhuang, Headquarters

Add.: No. 368, Xinshi North Road, Shijiazhuang, Hebei Province, China