Widely Used High Efficiency spiral Silica Sand Washing Machine

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Type:Spiral Sand Washer

- Capacity:20-30t,h

- Water Consumption:10-80t,h

- Speed of Screw:26rpm

- Motor Type:AC Motor

- Motor Power:11KW

Base Info

- Certification:ISO, CE, TUV

- Rotation Speed:0.8-1.2 r,min

- Wheel Bucket Diameter:2200mm

- Screw Diameter:750mm

- Product Name:Widely Used High Efficiency spiral Silica Sand Was

- Keyword:Widely Used High Efficiency spiral Silica Sand Was

- Application:Silica Sand Washing

- Installation:Engineers Guide

- Market:Europe

- Price:Negotible

- Advantage:Energy Saving Sand Washing Machine

- Motor:5.5-30kw

- Usage:River Sand ,Sea Sand

- Raw Material:Carbon Steel

- Transport Package:Wooden Case, Standard Container

- Specification:LXS-762

- Trademark:hengchang

- Origin:China

- HS Code:8474100000

- Production Capacity:10 Set,Day

Description

Basic Info.

Certification ISO, CE, TUV Rotation Speed 0.8-1.2 r/min Wheel Bucket Diameter 2200mm Screw Diameter 750mm Product Name Widely Used High Efficiency spiral Silica Sand Was Keyword Widely Used High Efficiency spiral Silica Sand Was Application Silica Sand Washing Installation Engineers Guide Market Europe Price Negotible Advantage Energy Saving Sand Washing Machine Motor 5.5-30kw Usage River Sand ,Sea Sand Raw Material Carbon Steel Transport Package Wooden Case, Standard Container Specification LXS-762 Trademark hengchang Origin China HS Code 8474100000 Production Capacity 10 Set/DayProduct Description

1.Product Application Of Spiral Screw Silica River Sand Washing MachineChina Mining Spiral Sand and gravel washing machine is applicable to sand washing, sand classification and dehydration the construction site, sand factory, glass factory, hydropower station, high-speed railway and highway for. It is also applies to ore dressing plant for the ore classification after ore grinding. XLS series have the advantages of low power consumption and high neatness

2.Main Features Of Spiral Screw Silica River Sand Washing Machine

1. Simple structure, the impeller bearing is isolated from water, greatly to prevent the bearing due to flooding, sand and pollutants lead to the damage.

2. There is little loss for medium-sized and fine sand or fine stone powder. The product is met to national standards, such as "sand for construction".

3. There is no other wearing part except the screen mesh.

4. Long service life and few times for maintenance.

3.Working principle Of Spiral Screw Silica River Sand Washing Machine

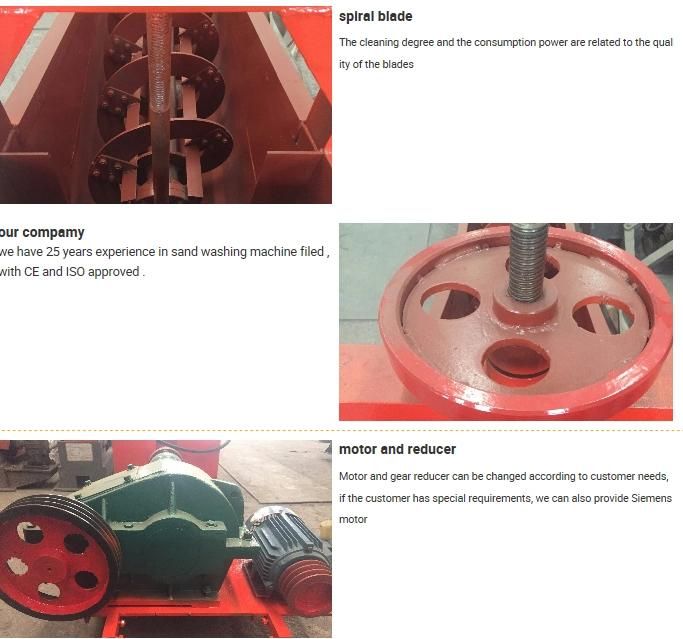

Sand washing machine drives the impeller in the water groove to move like a circle transmitted by electric motor and decelerator, and then mixes, overturns, cleans and discharges the sand or slag pellets in the water groove.

4.Our Company

Gongyi Hengchang Metallurgy Building Material Equipments plant was built in 1992, is a professional manufacturer specializing in the production of mineral beneficiation equipments, sand and stone crushing equipments, briquetting equipments, coal preparation equipments, drying and calcining equipments, cement plant equipments and compound fertilizer equipments. The products are widely used in mineral processing, metallurgy, building materials, chemicals, electricity, petroleum, coal, transportation, fertilizer , gas industry

5.Parameters Of Spiral Screw Silica River Sand Washing Machine

| Model | Spiral Dia.(mm) | Rotate Speed | input Size | Water Consumption | Capacity | Power (Kw) | Weight (Kg) |

| LXS -508 | Φ508 | (r/min) | (mm) | (T/h) | (T/h) | 5.5 | 2670 |

| LXS -610 | Φ610 | 38 | ≤10 | 6-40 | 20-30 | 7.5 | 3800 |

| LXS -762 | Φ762 | 32 | ≤10 | 6-50 | 30-40 | 11 | 4020 |

| LXS -914 | Φ914 | 26 | ≤10 | 9-63 | 75 | 11 | 6500 |

| LXS-1118 | Φ1118 | 20 | ≤10 | 10-80 | 100 | 15 | 8690 |

| LXS -1500 | Φ1500 | 18 | ≤10 | 27-168 | 175 | 18.5 | 16580 |

| 2LXS -762 | Φ762 | 13 | ≤10 | 27-180 | 220 | 11×2 | 8140 |

| 2LXS -914 | Φ914 | 26 | ≤10 | 136-182 | 145 | 11×2 | 13500 |

| 2LXS-1118 | Φ1118 | 21 | ≤10 | 120-150 | 200 | 15×2 | 19800 |