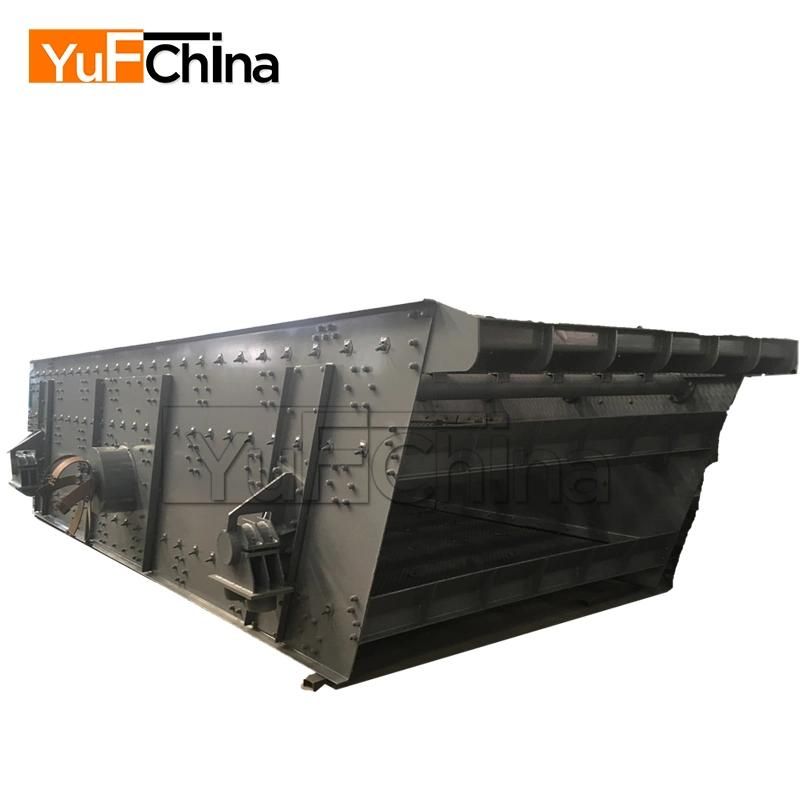

Hot Sale for High Carbon Vibrating Screen for Crusher Machine

ZHENGZHOU YUFENG HEAVY MACHINERY CO., LTD.- Type:Gravity Separator

- Voltage:440V

- Weight:9.85

- Material:Carbon Steel

- Certification:ISO9001:2000

- Energy Saving:Energy Saving

Base Info

- Model NO.:3YK2154

- Warranty:1 Year

- Color:Customised

- Customized:Customized

- Condition:New

- Trademark:YUFCHINA

- Origin:Henan China

- Production Capacity:1000 Per Year

Description

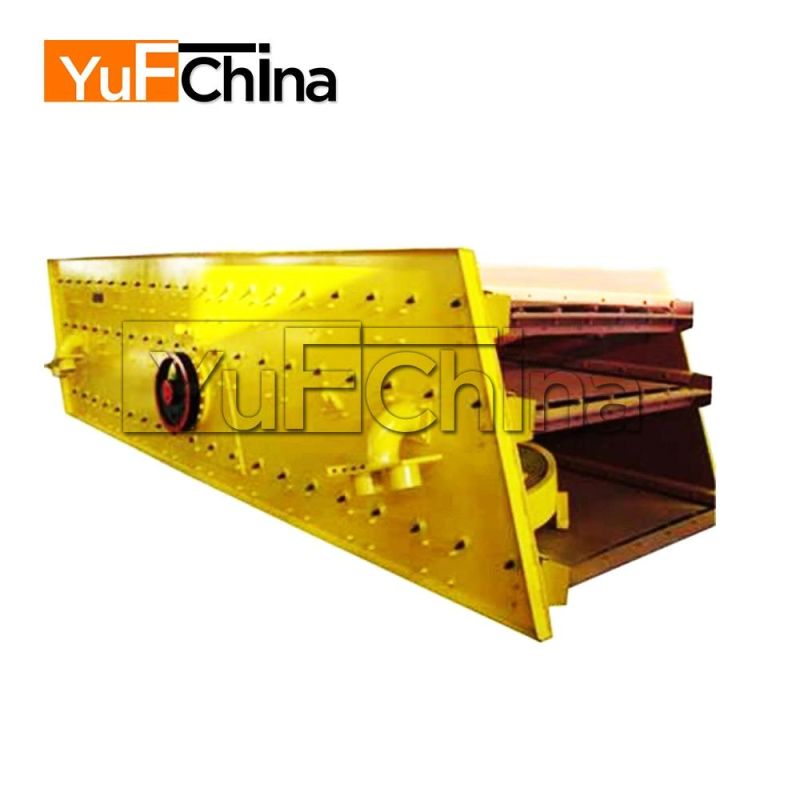

Performance and Features

1.Common features and performance of our Circular Vibrating Screen

High screening efficiency

Strong vibration force created

Adoption of punching sieve or steel made screening mesh in order to prevent blockage.

Screen body connected by using high strength screw bolts.

Adopts spring steel woven mesh or perforated sieve-plate, which is helps to prolong the service life and prevent blockage.

Rubber vibration spring is used to reduce noise pollution and provide smooth vibration operation.

2.Drive and Mounting of Circular Vibrating Screen <p > Drive is by electric motor and cardan shaft to the main drive shaft equipped with a single unbalance weight where required additional v-belt can be provided. The drive shaft is mounted on heavy duty roller bearing sets, lubricated with grease or oil. Like the linear vibratory screens, circular vibrating screens are mounted on reinforced rubber springs to prove the same benefits in performance and longer lifespan.

Vibrating screen Advantages

1) Simple structure and easy maintenance.

2) Adopting the structure of small amplitude, high frequency and large obliquity,

3) High efficiency, large handling capacity

4) Long service life, low running cost and low noise.

Work principle

Circular Vibrating Screens operate using indirect excitation of the screen mesh. The entire screen frame is driven by unbalance masses, which produce a circular vibrating motion. It used eccentric block to produce strong exciting force. The directionless vibrations of the circular vibrating system have a steep launch angle and the screen area must be further tilted in order to achieve a suitable transport speed.

Our service

Assist clients to choose the suitable machine

Design and manufacture machines according to customer's special requirements

The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design the best processes and program

Arrange for visiting our factory, assist them to handle relative procedure, such as visa.

Make sure goods prepared within delivery time;

Pre-check and accept products ahead of delivery;

Prepare documents required to help customer pass customs clearance.

Help clients to make Project evaluation and feasibility analysis and draft solving plans.

Provide technical engineers to guide the installation;

Train clients worker how to operate;

Offer spare parts at a best price for long term.