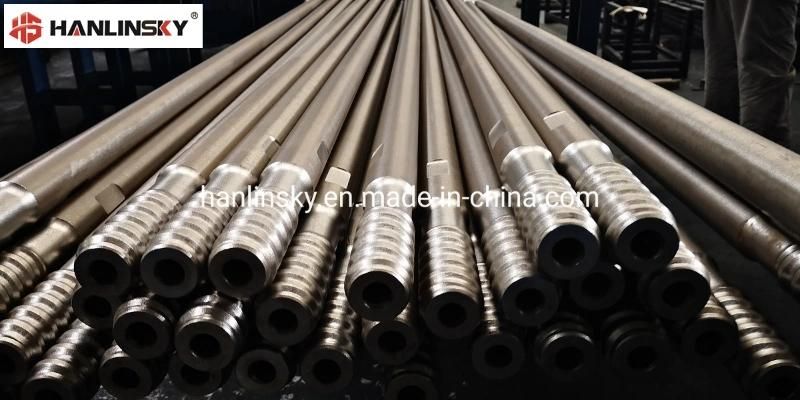

Tophammer Threaded Drill Rods with R32, R38, T38, T45, T51 Thread

Hunan Hanlinsky International Corporation- Certification:CE, ISO 9001:2000, SGS

- Standard:GB, GOST, API

- Surface Treatment:Spray-Paint

- Material:Alloy Steel

- Applications:Mining, Quarrying, Benching

- Advantage:High Durability

Base Info

- Model NO.:R32, R38, T38, T45, T51 Thread

- Delivery Time:in Stock or 15 Days

- Transport Package:Steel Pallets

- Trademark:Hanlinsky

- Origin:Changsha, China

- HS Code:82071990

- Production Capacity:8000 Pieces , Month

Description

Basic Info.

Model NO. R32, R38, T38, T45, T51 Thread Delivery Time in Stock or 15 Days Transport Package Steel Pallets Trademark Hanlinsky Origin Changsha, China HS Code 82071990 Production Capacity 8000 Pieces / MonthProduct Description

Our CompanyHunan Hanlinsky International Corporation is a leading chinese supplier and supporter of high quality mining machineries, rock drilling tools, new materials, chemicals and relative services for mining industry. The corporation delivers the full, economical and sustainable solutions for global mining partners.

Description

Hanlinsky offer all kinds of top hammer drill rods, which are available by integral rods, tapered rods and threaded rods, etc. They are characterized by high quality, high performance, reasonable price and long service life.

For enhancing superior wear resistance and impact toughness, Hanlinsky adopt high quality alloy steel bar and special heat treatment for our rods, so that it can withstand the toughest rock in drilling and transmit intensive impact energy into the rock with the least loss of energy. They are widely used in all kinds of drilling, such as open-pit mining, underground mining, quarrying, tunneling, benching and engineering construction.

For superior quality and high durability, our top hammer drill rods enjoy the great reputations from different countries, such as Australia, South Africa, Chile, Mexico, Russia, Kazakhstan, Iran, Vietnam and so on.

Product Features

1. High Strength Alloy Steel with strict quality control for steel smelting and rolling.

2. Scientific and standard thread tooth designs and strengthening for Excellent Thread Connection.

3. Special heat treatment by fully carburization, quenching and tempering for Superior Surface Hardness and Strength Index.

4. Good Adaptbility for all kinds of drills and drill rigs and ensure economic operation.

Specification

(1) Threaded Drill Rods

| Description | The drill rods are made by the hollow drill steel with round type or hexagonal type. The hollow hole is used for transmitting water or air during drilling, and the threads can be used for connecting couplings, shanks or bits. |

| Detailed Name | Drifter Rod / Speed Rod / Extension Rod / MF Rod / Shank End Rod |

| Thread Type | R25, R28, R32, R38, T38, T45, T51 |

| Rod Size | Hex.22, Hex.25, Hex.28, Hex.32, Hex.35, Dia.39mm, Dia.46mm, Dia.52mm |

| Length | 610mm - 6400mm |

(2) Tapered Drill Rods

| Description | The drill roads usually have a forged collar to maintain the proper shank striking face position and used for rock drilling, blasting holes and other drilling works in the mining, quarrying or engineering construction. It works with tapered drill bits and has different length for various applications. |

| Another Name | Tapered Rod / Tapered Drill Steel |

| Shank Size | Hex.22×108mm, Hex.25×159mm |

| Tapered Degree | 7°, 11°, 12° |

| Length | 610mm - 8000mm |

(3) Integral Drill Rods

| Description | The drill rods are used by a hand held drill machine in underground mining and for small hole drilling. They can reduce the expense of impact energy and improves the drilling speed and efficiency |

| Shank Size | Hex.19mm, Hex.22mm, including plug hole rods |

| Head Diameter | 24 - 42mm |

| Length | 400mm - 4800mm |

Note: For more details or other specifications, please make an inquiry to our engineers.