Simple Silica Sand Rotary Drum Dryer Equipment

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Model:Φ1.2×12

- Object:Slag

- Voltage:as Customer·s Requirement

- Drum diameter:Φ1200mm

- Certification:CE, ISO9001:2008

- Energy Saving:Energy Saving

Base Info

- Model NO.:rd

- Warranty:2 Years

- Color:as Your Requirements

- Customized:Customized

- Condition:New

- Product Name:Simple Silica Sand Rotary Drum Dryer Equipment

- Keyword:Rotary Drum Dryer

- Material:Q235 Steel

- Plate Thickness:12-20mm According to Different Model

- Spare Parts Supply:Long Term, Good Price

- After Sale Service:Long Term

- Structure:Rotary Type Drier

- Type of Atomization:Rotary Atomization

- Sprayer:Air-Flowing Type

- Transport Package:Standard Packing

- Specification:ISO9001: 2008

- Trademark:Hengchang

- Origin:Gongyi City, Henan Province, China

- HS Code:8419399090

- Production Capacity:200 Set,Sets Per Month

Description

Basic Info.

Model NO. rd Warranty 2 Years Color as Your Requirements Customized Customized Condition New Product Name Simple Silica Sand Rotary Drum Dryer Equipment Keyword Rotary Drum Dryer Material Q235 Steel Plate Thickness 12-20mm According to Different Model Spare Parts Supply Long Term, Good Price After Sale Service Long Term Structure Rotary Type Drier Type of Atomization Rotary Atomization Sprayer Air-Flowing Type Transport Package Standard Packing Specification ISO9001: 2008 Trademark Hengchang Origin Gongyi City, Henan Province, China HS Code 8419399090 Production Capacity 200 Set/Sets Per MonthProduct Description

Products Description:

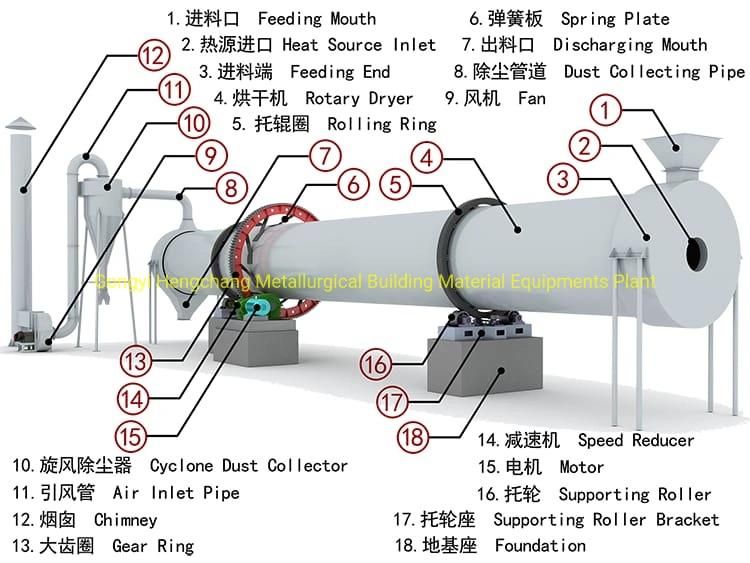

Rotary dryer

Rotary drum dryer, also known as drum dryers or tumble dryers, are among the most common and widely used dryers in mining equipment. Suitable for the drying of magnetic and heavy, floating concentrates of metallic and non-metallic minerals, clay in the cement industry, and coal slime in the coal mining industry. It is characterized by high productivity and easy operation. The tumble dryer cylinder is a horizontal rotary cylinder. The inside of the rotary cylinder is staggered with various staggered angles from the front to the back. The rotary kiln body is equipped with different types of refractory bricks according to the requirements, and is protected from falling at the feed end. Material is provided with a door circle and spiral copy board. It has the advantages of reasonable structure, excellent production, high output, low energy consumption and convenient operation.

Details Images:

Working principle:

The wet materials are conveyed to the hopper through the belt conveyor or bucket elevator, and then enter into the feed end through the hopper charger and the feeding pipe in sequence. The inclination of the feeding pipe must be greater than the natural inclination of materials in order to make the materials flow into the dryer smoothly. The dryer cylinder with slight inclination with the horizontal line. The materials enter from the higher end, and the heat carrier enters from the lower ender; the two contact each other from opposite directions, but there are also circumstances that the heat carrier flows into the dryer body together with the material.

Product Characteristics:

1. The transmission gear adopts the pin and replaceable gear, which replaces the traditional cast steel gear, saves cost and investment, and greatly reduces the maintenance cost and time.

2. The centralized control system can be used to realize the centralized monitoring and management of large-scale enterprise microcomputers.

3, greater production capacity, continuous operation;

4, the structure is simple, easy to operate;

5, less failure, low maintenance costs;

6, a wide range of applications, you can use it to dry granular materials, for those with large adhesion material is also very favorable;

7. The operation flexibility is large, and the output of the products allowed in the production has a large fluctuation range, which will not affect the quality of the products;

8, easy to clean.

Product Paramenters:

| Model (mm) | Speed(r/min) | Slope(%) | Inlet Air Temperature(°C) | Power(kw) | Capacity(t/h) | Weight(t) |

| Φ800×8000 | 3-8 | 3-5 | ≤700 | 4 | 0.8-2 | 3.5 |

| Φ1000×10000 | 3-8 | 3-5 | ≤700 | 5.5 | 1-3 | 5.6 |

| Φ1200×10000 | 3-8 | 3-5 | ≤700 | 7.5 | 2-3.5 | 13.5 |

| Φ1200×12000 | 3-8 | 3-5 | ≤700 | 11 | 2.5-4 | 14.2 |

| Φ1500×12000 | 2-6 | 3-5 | ≤800 | 11 | 4-6 | 18.5 |

| Φ1500×15000 | 2-6 | 3-5 | ≤800 | 18.5 | 5-8 | 21 |

| Φ1800×18000 | 2-6 | 3-5 | ≤800 | 18.5 | 6-12 | 31 |

| Φ2000×18000 | 1.5-6 | 3-5 | ≤800 | 22 | 8-15 | 35 |

| Φ2200×12000 | 1.5-6 | 3-5 | ≤800 | 22 | 13-15 | 31.6 |

| Φ2200×14000 | 1.5-6 | 3-5 | ≤800 | 22 | 14-16 | 33.5 |

| Φ2200×16000 | 1.5-6 | 3-5 | ≤800 | 30 | 14-18 | 36 |

| Φ2400×18000 | 1.5-6 | 3-5 | ≤800 | 45 | 16-22 | 42.8 |

| Φ2400×20000 | 1.5-6 | 3-5 | ≤800 | 45 | 18-25 | 52 |

| Φ3000×20000 | 1.5-6 | 3-5 | ≤800 | 55 | 25-30 | 77.8 |

| Φ3000×25000 | 1.5-6 | 3-5 | ≤800 | 55 | 28-34 | 87.5 |

Company profile: