Professional Magnetic Drum Separator with Wet Magnetic Separation, Coal, Non-Metallic ...

Luoyang Zhongtai Industries Co., Ltd.- Type:Magnetic Separator

- Voltage:220V

- Weight:>10T

- Certification:ISO9001:2008

- Warranty:1 Year

- Color:Black

Base Info

- Model NO.:professional Magnetic drum separator

- Customized:Customized

- Condition:New

- After-sales Service:Twenty Four Hour Online

- Machinetype:Ore Dressing Machine

- Apacity:10-280t,H

- Feature:Automatic Control, to Facilitate The Change Proces

- Power(Kw):1.5-11

- Transport Package:Simple Packaging

- Trademark:ZTIC

- Origin:Luoyang, Henan

- Production Capacity:500PCS,Year

Description

Magnetic Separator

Supply Ability:100 Set/Sets per Month

Production capacity:10-280t/h

Type:Ore dressing machine

Feature:Automatic control, To facilitate the change process, High versatility

Overview: Magnetic separator can be divided into dry magnetic separator and wet magnetic separator. The magnetic separator is the most widely used mining machine with advantages of simple structure, easy to operate, easy to maintain and so on. The magnetic separator is widely used in iron powder removal, and magnetic separator is also widely used in resource recovery, timber industry, mining, ceramic, chemical, food and so on. The magnetic separator is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with granularity below 3mm, and the iron removal of coal, non-metallic mineral, building material and other material.

Structure: The magnetic separator is mainly composed of drum, roller, brush roller, magnetic system, tub and transmission parts. Cylinder is rolled welding by 2-3 mm stainless steel plate, and the end cover is aluminum casting connected by stainless steel screw and barrel. Motor regulates motor speed through the reducer, which drives the cylinder and magnetic roll do rotary motion. Magnetic system is open, installed in inside cylinder and all bared magnetic. Magnetic block is installed in the plate of yoke by stainless steel bolt, and the shaft of the yoke is out of the barrel. The end shaft is fixed with turn arm, which can adjust the magnetic system angle. The working area of trough is made up with stainless steel, and the frame and other parts of the cell body is welded with ordinary steel.

Magnetic Separator Technical Data

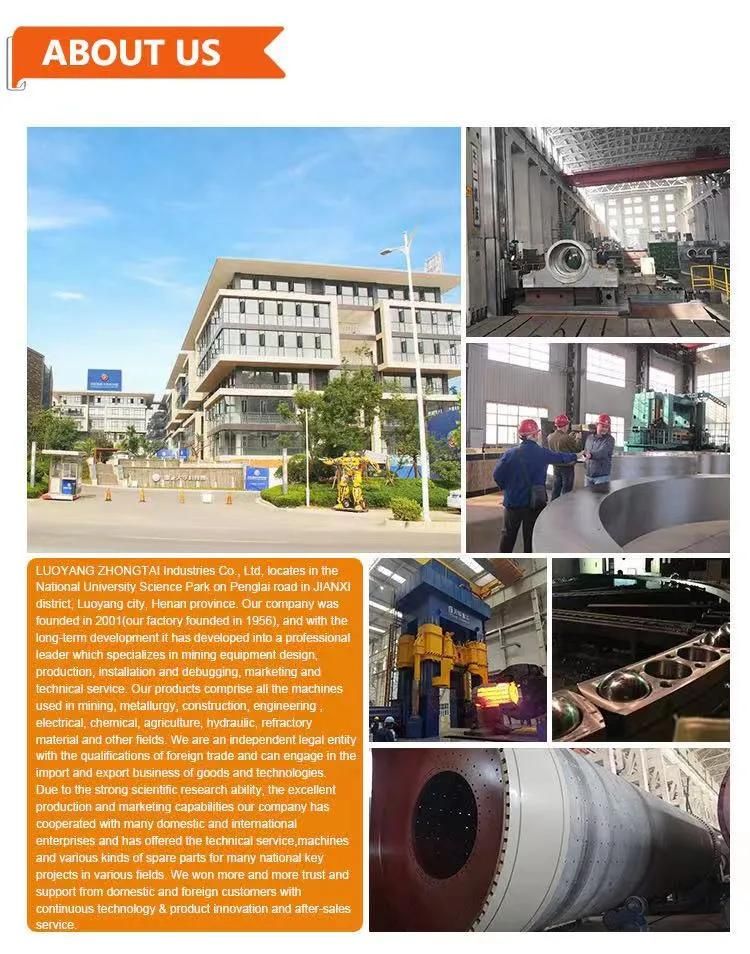

Company Information

After Sales Service

After Sales ServiceFAQ

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time

A: parts lead time 1-2months, machines 2-3months.

Q:Payment terms

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping

Q: Quality warranty?

A: guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: we can supply technical guide for machines running test and parts maintenance if end user needs.

FAQ

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time

A: parts lead time 1-2months, machines 2-3months.

Q:Payment terms

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping

Q: Quality warranty?

A: guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: we can supply technical guide for machines running test and parts maintenance if end user needs.

Aftersales service

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

ZTIC's Field Service Engineers are trained specifically in the CITIC brand group products but are capable of undertaking the servicing of other OEM brands.

Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time.

ZTIC also has an extensive capability in supplying all you consumable and electrical/ mechanical spare part needs.

Our mode of transport is taken according to each country's situation is different transportation, while our packaging, according to the latest customs situation, constantly updated, improved our packaging, we guarantee that you receive it within 3-7 working days to your product.

High quality service :

Best Service with after-sales service and consultation,we have an excellent customer service driven approach to our

business, unlike most sites we are consistently available via sales hotline, email, skype or MSN and always respond to

emails within 30 mins

Pre-Sales Service

• Provide details about the production procedure

• Assign engineers for installation and testing

Sales Service

• Customized solution designs

• Product rendering and steel structure drawing

• successful project examples and visits to our production and R&D base

After-Sales Service

• Two-year quality warranty with lifelong maintenance.

• Free guarantee repair (including labor and material): free repair service during the quality warranty period and reasonable charge for spare parts and maintaining service after the quality warranty period. We will never exempt our responsibilities on product owned defects.

• Responding time: upon receiving user's notification, we ensure 24-hour after-sales technical support.