Factory advantage| Professional and experienced technology team | | All products inspected before shipping with reasonable prices |

| Low MOQ and free sample |

| We are audited by SGS and passed the ISO9001:2008 certification |

Industries service | Industrial machine |

| Electronic and communication |

| Oil, gas,mining and petroleum |

| Construction industry |

| Equipment | CNC Machining Center, CNC Lathes, CNC Milling Machines, Punching and drilling machines, Stamping machines |

| Precision Processing | CNC machining, CNC turning and milling, laser cutting, drilling, grinding, bending, stamping, welding |

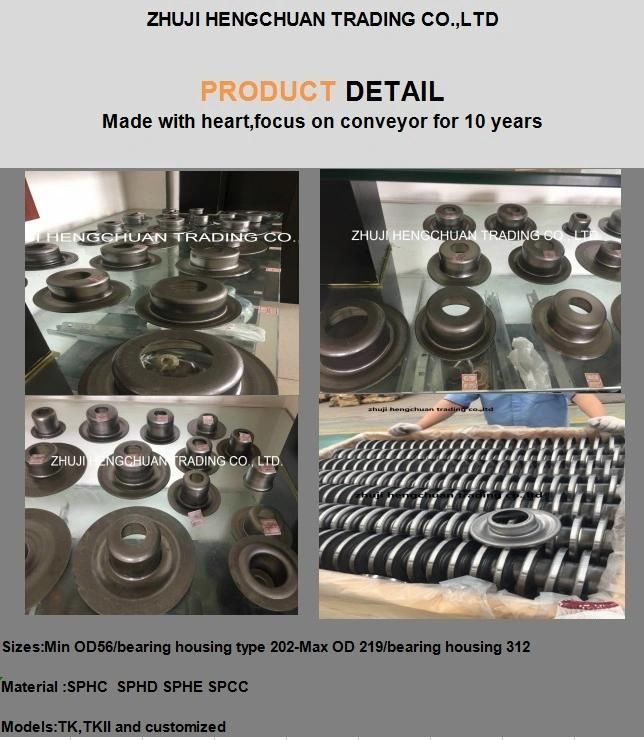

Standard Diameter

Standard DiameterLength Range

(mm) | Bearing Type

Min-Max | Shell Thickness of Roller | | | mm | Inch | | | |

| 1 | 63.5 | 2 1/2 | 150-3500 | 203 204 | 3.0mm-4.0mm |

| 2 | 76 | 3 | 150-3500 | 204 | 3.0mm-4.5mm |

| 3 | 89 | 3 1/3 | 150-3500 | 204 205 | 3.0mm-4.5mm |

| 4 | 102 | 4 | 150-3500 | 204 205 206 305 | 3.2mm-4.5mm |

| 5 | 108 | 4 1/4 | 150-3500 | 204 205 206 305 306 | 3.5mm-4.5mm |

| 6 | 114 | 4 1/2 | 150-3500 | 204 205 206 305 306 | 3.5mm-4.5mm |

| 7 | 127 | 5 | 150-3500 | 204 205 206 305 306 | 3.5mm-5.0mm |

| 8 | 133 | 5 1/4 | 150-3500 | 204 205 206 207 305 306 | 3.5mm-5.0mm |

| 9 | 140 | 5 1/2 | 150-3500 | 205 206 207 305 306 307 | 3.5mm-5.0mm |

| 10 | 152 | 6 | 150-3500 | 205 206 207 305 306 307 308 | 4.0mm-5.0mm |

| 11 | 159 | 6 1/4 | 150-3500 | 205 206 207 305 306 307 308 | 4.0mm-5.0mm |

| 12 | 165 | 6 1/2 | 150-3500 | 206 207 305 306 307 308 | 4.5mm-6.0mm |

| 13 | 177.8 | 7 | 150-3500 | 207 306 307 308 309 | 4.5mm-6.0mm |

| 14 | 190.7 | 7 1/2 | 150-3500 | 207 306 307 308 309 310 | 4.5mm-7.0mm |

| 15 | 194 | 7 5/8 | 150-3500 | 207 306 307 308 309 310 | 4.5mm-8.0mm |

| 16 | 219 | 8 5/8 | 150-3500 | 308 309 310 312 | 4.5mm-8.0mm |

Ends 1.Plain ends, | | 2.Threading at both side with plastice caps |

| 3.Threading at both side with socket/coupling. |

| 4.Beveled ends, and so on |

| Packing | 1.Water-proof plastic cloth, |

| 2.Woven bags, |

| 3.PVC package, |

| 4.Steel strips in bundles |

| 5.As your requirment |

| Usage | 1.For low pressure liquid delivery such as water,gas and oil. |

| 2.For construction |

| 3.Mechanical equipment |

| 4.For Furniture |

| Payment&Trade Terms | 1.Payment : T/T,L/C, D/P, Western union |

| 2.Trade Terms:FOB/CFR/CIF |

| 3.Minimum quantity of order : 10 MT (10,000KGS) |

| Delivery Time | 1.Usually,within10-20days after receiving your down payment. |

| 2.According to the order quantity |

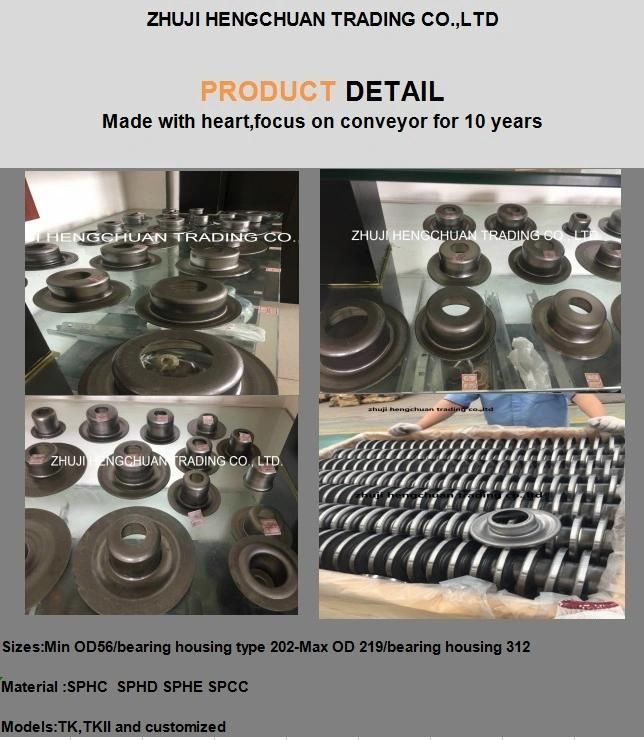

Conveyor Roller Tube

Conveyor Roller TubeSpecification | SANS657/3,ASTM513,AS1163,BS6323,EN10305 or equivalent international standard. | | Steel grade | S355/S230,C350,E235,Q235B |

| Sizes | 63.5mm-219.1mm ect |

Ovality tolerance of body | ≤0.4mm(60.3mm-152.4mm) |

| ≤0.5mm(159MM-168.3mm) |

| ≤0.6mm(178mm-219mm) |

| Straightness | 2000:1 |

if you are interesting in our products or want any further information, please feel free to contact us!

I am looking forward to your reply.

Best regards

Ruth

Website: hengchuanwin.en.made-in-china.com.

ZHUJI HENGCHUAN TRADING CO., LTD

1801 Huahui Building, No.268 Xierhuan Road, Zhuji City, Zhejiang Province, China

Standard Diameter

Standard Diameter

if you are interesting in our products or want any further information, please feel free to contact us!

if you are interesting in our products or want any further information, please feel free to contact us!