Supporting Roller for Rotary Kiln with Cement, Ore Processing, Chemical Industry

Luoyang Zhongtai Industries Co., Ltd.- After-sales Service:Twenty-Four Hours Online

- Warranty:Three to Six Momths

- Weight:From 3 Tons to 200 Tons Per Piece

- Standards:ASTM,BS,NF,DIN,JIS and So on;

- Material:Zg20simn,Zg50mn,Zg35s

- Range of Application:for Rotary Kiln&Rotary Dryer

Base Info

- Model NO.:Rotary kiln support roller

- Max.Od in Our Business Line:Within 10,000mm

- Kiln Tyre Application:Used for Industrial Purpose, and Especially Used O

- Transport Package:Rotary Kiln Support Roller and Tyre

- Specification:Rotary kiln support roller

- Trademark:ZTIC

- Origin:Luoyang, Henan

- Production Capacity:2000PCS,Year

Description

Rotary kiln is widely used in processing industries, such as cement, ore processing and chemical. The kiln is a cylindrical shell slightly inclined to the horizontal position and supported by tyres. A Girth gear and pinion assembly rotates the entire system. Material enters the kiln at the upper end and moves to words the lower end. With continuous mixing and a supply of hot air the desired chemical reaction is completed at the lower end and thus the processing is continuous. The kiln shell has a fire brick lining to protect the outer steel shell from the high temperatures existing inside. The tyre is a cylindrical ring supporting to the kiln shell. Tyre is cylindrical cast or forged sin gle ring. Following picture gives general arrangement of tyre and rollers.

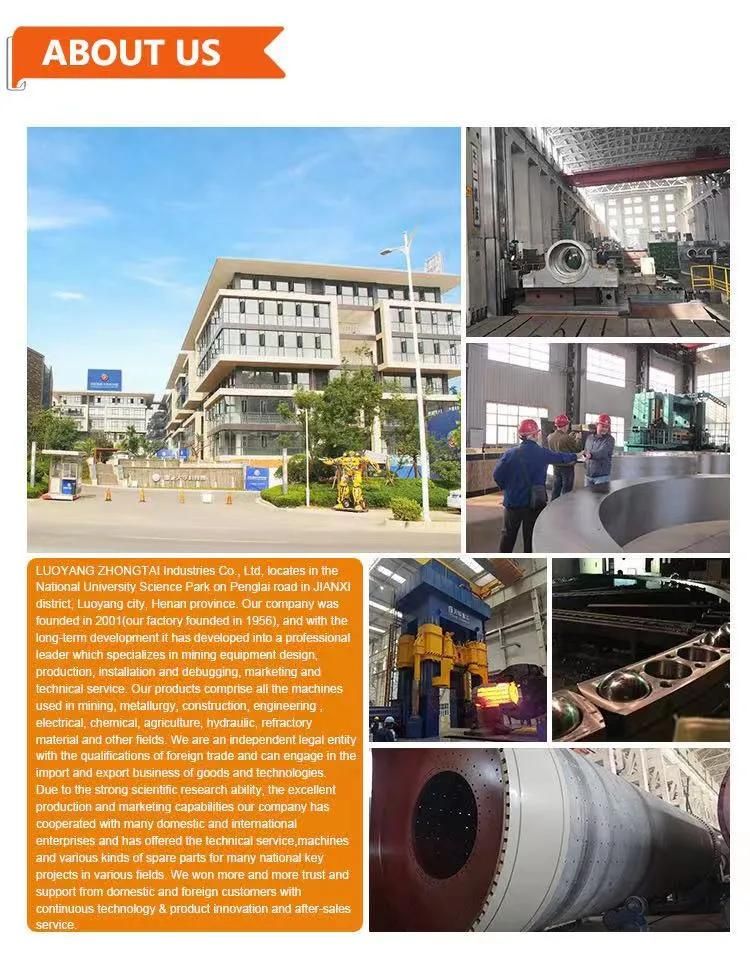

Company ProfileThe products can be widely used in the area of cement mill,rotary kiln,shipbuilding,

3) Chemical Test Report

It is important to take periodic measurements and analysis on the kiln and solve the problems on time to have a hassle-free kiln. Despite it seems like a huge construction, a hot rotary kiln is similar to a nylon bag full of water. The kiln stands over the supporter rollers and the shell shows oscillation because of the ring which is thicker than the shell. Ring presses the shell down and creates ovality. By the time the ovality carries itself to whole shell and creates a crank. The surface between ring and supporter roller reduces.

On the other hand; tire and thrust roller contact surface problems causes poor contact and wavy structure on surfaces and irregular movements caused by waves. This situation increases the surface stress and heat-ups the roller beds. Also wrong angles on the surfaces of thrust roller and tire machines the surface and increases the problems.

Harmonic movements create timing marks on the tire surface which behaves like a gear. Geared from starts the small vibrations which will increase and wobble the whole kiln in a very short time.

Such a hassled kiln can be tamed only by following where the problem is going and early intervention by grinding (resurfacing) the tire, supporter rollers and thrust roller surfaces. Yet we cannot expect to align such a kiln for a long term use.

For carrying tire and rollers out of the problematic position, the only way is machining and grinding the surface. As a result; contact surface will increase, surface stress and connected problems will end, vibration will end, it will be possible to align the kiln for long term expectations. A hassle-free kiln will collapse down the working costs dramatically.

FAQ

FAQAfter Sales Service

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

ZTIC's Field Service Engineers are trained specifically in the CITIC brand group products but are capable of undertaking the servicing of other OEM brands.

Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time.