High Chromium Wear Parts for Vertical Tower Grinding Mill Liner China OEM Factory

Maanshan City Hyton Heavy Industry Technology Development Co., Ltd.- Certification:ISO 9001:2008

- Standard:ASTM

- Surface Treatment:Polishing

- Manufacturing Process:Casting

- Material:Cast Iron

- Transport Package:Standard Packing

Base Info

- Specification:standard size

- Trademark:Hyton

- Origin:Maanshan China

- HS Code:84749000

- Production Capacity:30000 Ton Per Year

Description

Basic Info.

Specification standard size Trademark Hyton Origin Maanshan China HS Code 84749000 Production Capacity 30000 Ton Per YearProduct Description

High Chromium Wear Parts for vertical Tower Grinding mill liner china Oem factory

Application

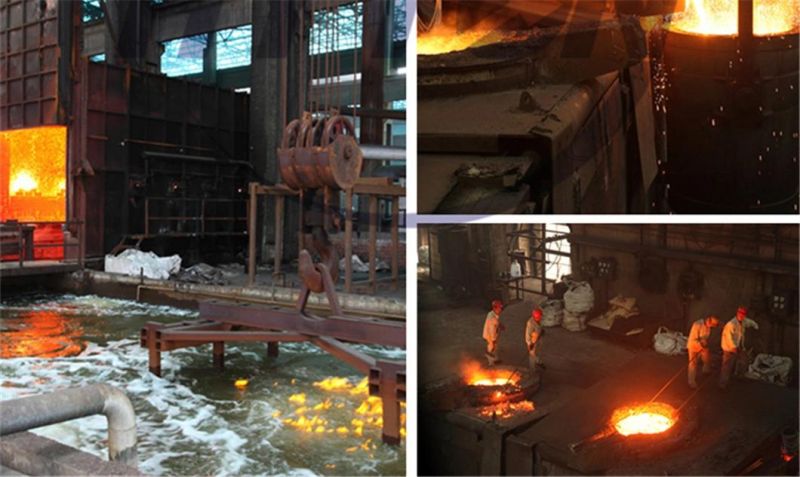

High Chrome steel wear resistance parts wildely used in the tower mill machine ,Wildely use the high Chrome and Super high chromeas its standard material .

Marterial Element :Cr (12-28),Mo(0-1),Ni(0-1),Cu(0-0.5).

Company Profile

Ma'anshan Hyton Heavy Industry Technology Development Co., Ltd. is a leading enterprise in

the large-scale engineering machinery wear-resisting casting industry in Anhui Province,Maanshan City. As a new high-tech enterprise professionally manufacturing wear-resisting casting product Which specialized in manufacturing and research of High manganese and high Chrome wear parts . After ten years of rapid development, Hyton has now become a renowned enterprise in China's wear-resisting casting industry; it has become one of the famous supplier of wear parts for crusher and concrete mixer .

Established in June 2004, the company is now undertaking a National Torch Program Project,and five of its patented products have been honored as the "New High-Tech Product" of Anhui Province two of which have been listed into the New Products Program of Anhui Province.The company's wear-resisting casting products have been praised to be the "Famous-brand Products of Anhui Province", the company has been appraised as a "Trustworthy" unit of Anhui Province for many consecutive years. It was selected as one of the first batch of enterprises in Bowang District to be cultivated as the "Little Industrial Giants". In April 2014, Hyton Heavy Industry been selected as the 2ND Top 100 China Foundry Industry Enterprises again , which isanother landmark honor after being recognized as the "Professional, Refined, Special and New"Enterprise in Anhui Province.

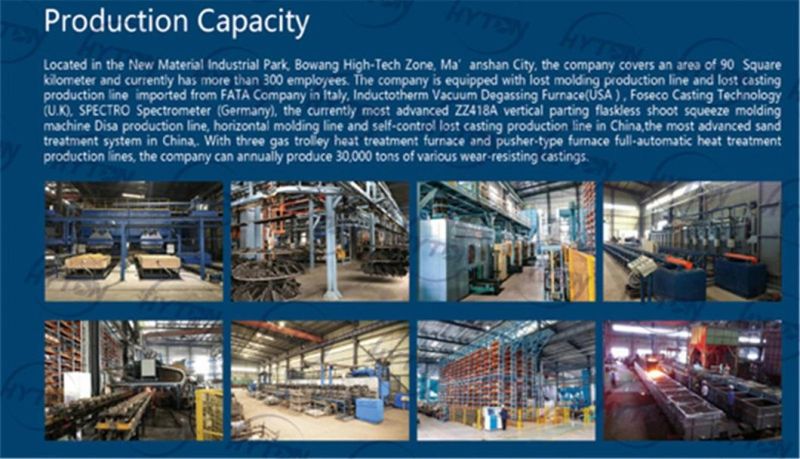

Located in the New Material Industrial Park, Bowang High-Tech Zone, Ma'anshan City, thecompany covers an area of 90 Square kilometer and currently has more than 300 employees. Thecompany is equipped with lost molding production line and lost casting production line imported from FATA Company in Italy, Inductotherm Vacuum Degassing Furnace(USA), Foseco Casting Technology(U.K), SPECTRO Spectrometer (Germany), the currently most advanced ZZ418A vertical parting flaskless shoot squeeze molding machine Disa production line, horizontal molding line and self-control lost casting production line in China,the most advanced sand treatment system in China,. With three gas trolley heat treatment furnace and pusher-type furnace full-automatic heat treatment production lines, the company can annually produce 30,000 tons of various wear-resisting castings.

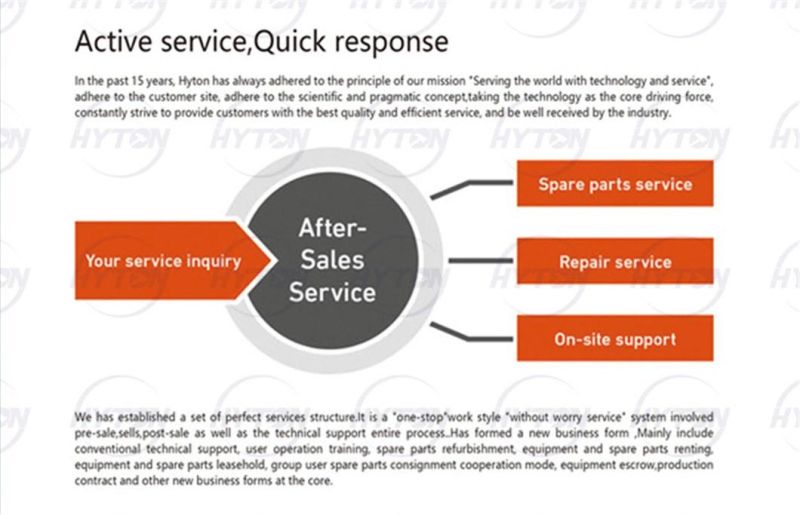

After Service

After goods packaged well , we need only 1 day ship good to Shanghai port ,which means that most of the spare parts you bought from Hyton ,it will get your port within 45 days all around the world if ship by sea .