Mining Machine Parts Nordberg HP200 Cone Crusher Liner Filler Backing Compound

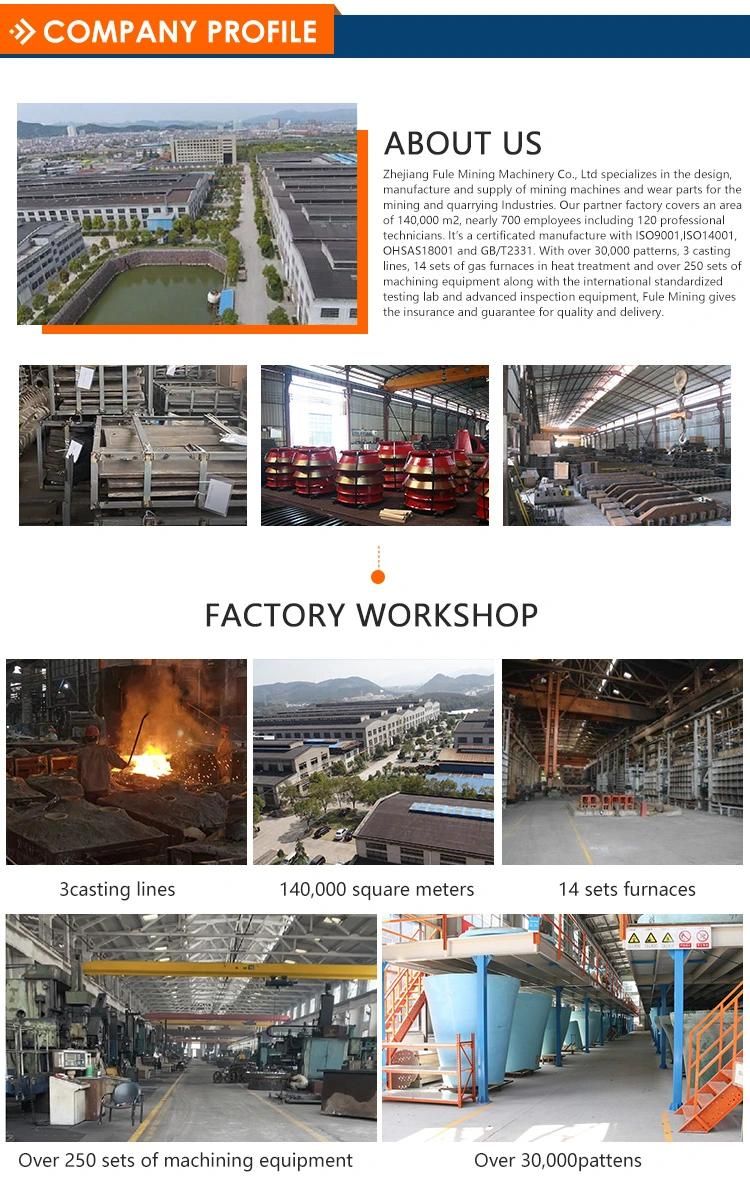

Zhejiang Fule Mining Machinery Co., Ltd.- Certification:ISO 9001:2000

- Standard:GB

- Surface Treatment:Without Processing

- Manufacturing Process:Casting

- Material:Epoxy Resin

- Brands We Have:Nordberg Sandvik Symons Terex Telsmith

Base Info

- Sample Order:Available

- Usage:Cone Crusher Wear Parts

- Drawing:Original,Customized

- Advantage:Wear Resistant

- Color:as Customer′s Request

- Guarantee:Same as Original

- Product Type:Cone Crusher Parts

- Product Name:Cone Crusher Parts

- Machine Type:Cone Crusher

- Condition:New

- Heat Treatment:Anneal, Quenching, Tempering

- Logo:Customized

- Size:Customized

- H.S. Code:8474900000

- Transport Package:in Box

- Specification:as per parts number or customer′s request

- Trademark:FULE

- Origin:Jinhua, Zhejiang

- HS Code:8474900000

Description

Basic Info.

Sample Order Available Usage Cone Crusher Wear Parts Drawing Original/Customized Advantage Wear Resistant Color as Customer′s Request Guarantee Same as Original Product Type Cone Crusher Parts Product Name Cone Crusher Parts Machine Type Cone Crusher Condition New Heat Treatment Anneal, Quenching, Tempering Logo Customized Size Customized H.S. Code 8474900000 Transport Package in Box Specification as per parts number or customer′s request Trademark FULE Origin Jinhua, Zhejiang HS Code 8474900000Product Description

Backing Compound

Product details

| Product name | Cone Crusher High Manganese Mantle |

| Usage | Cone Crusher Wear Parts |

| Application | cone crusher |

| Material | |

| Color | Customized |

| Packing | customized |

| Keyword | backing compound |

| Machine Type | cone crusher |

| Logo | customized |

| H.S. Code | 8474900000 |

FAQ1. Q: What kinds of products do you offer?

FAQ1. Q: What kinds of products do you offer?A: We are mainly on parts for jaw crushers and cone crushers and also impact crusher and hammer crusher spare parts.

2. Q: What kind of materials are using for the products?

A: We supply wear parts with various manganese content and for jaw crushers and cone crushers mostly the 13% and 18% manganese steel.

3. Q: What's the maximum single weight that can be casted, What is your processing capacity per day ?

A: The single weight that can be casted at one time is 10 tons. The capacity is 35 tons per working day.

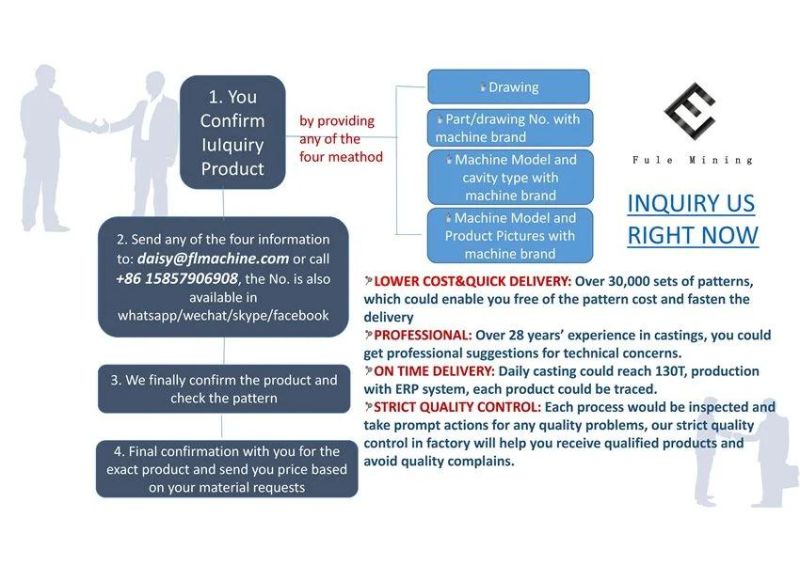

4. Q: What information do we need to provide to you in order to confirm our parts order?

A: For standard parts, just provide us the drawing No. so we could confirm the exact parts.

For non-standard products, provide us your drawings or detailed specifications for our technical staff could make the drawing.

6. Q: May we visit the factory?

A: Yes, you can visit the factory during working days and our sales team would be happy to assist you.

It is possible, to take the high speed train from Shanghai station to the factory and we would pick you up at train station or airplane station in Shanghai.

7. Q: If your product has inferior quality or quality problem after we use them what happens next?

A: First, you have to provide us photos of the problem part and also provide photos of the machine so we can see how the part was installed and gather other necessary information to define the cause of the problem.

If it is indeed a quality problem of the product itself, we would offer compensation to you and also figure out solutions to avoid this kind of quality problem in the future. If the problem is caused by clients, we would provide the technical suggestions to avoid same problems.

8. Q: Why you have to choose us from multiple vendors?

As a manufacture for high manganese parts since 1993, we have strict quality control and quick delivery, we know quality is what matters the most and we give customers the quick response and the most competitive price.

Contact us for more information on our existed drawings, patterns and prices.