High Quality Taper Cross Drill Bit Mzcr40-T12*8-7 with Tungsten Carbide

WUHAN KINGDRILLING DIAMOND CO., LTD.- Certification:ISO 9001:2000, SGS

- Standard:GB

- Surface Treatment:Spray-Paint

- Manufacturing Process:Forging

- Material:Carbon Steel

- Customized:Customized

Base Info

- Model NO.:MZCR40-T12*8-7

- Quantity:Small Quantity Is Acceptable

- Usage:Pneumatic, Coal, Water Well, Mining

- Transport Package:Wooden Case

- Trademark:MING

- Origin:Made in China

- HS Code:8207199000

- Production Capacity:20000PCS,Year

Description

Basic Info.

Model NO. MZCR40-T12*8-7 Quantity Small Quantity Is Acceptable Usage Pneumatic, Coal, Water Well, Mining Transport Package Wooden Case Trademark MING Origin Made in China HS Code 8207199000 Production Capacity 20000PCS/YearProduct Description

Manufacture of Down The Hole Taper Cross & X BitsFeature: Tapered drill bits connect tapered drill steel of rock drill for drilling holes

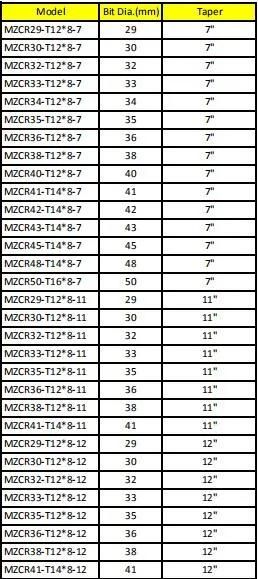

Types: Tapered chisel bit,tapered cross bit and tapered button bit.

The drilling depth is usually 15m-18m of hardness grade F8-14.

More details:

This kind of bit usually used to drill holes with a depth size no more than 5 meters and the diameter scope between 20-45 mm by hand hold drills, such as Y6, Y10, Y24, mainly used in natural dimensional stone quarry for small hole drilling, block's trimming and 2nd splitting for small blocks. It is used to match Hexagonal 22 mm and Hexagonal 12 mm tapered drill steel with 4/6/7/11/12 degree.

Our Advantages as below:

- High quality steels materials. Steel is from TIMKEN and Tungsten carbide are YK05, or T6 from Element Six in Germany

- Kingdrilling DTH tools are forged by advanced electron-hydraulic forging hammer.

- Advanced heat-treatment equipment: multipurpose furnace heat treatment.

- Completed moulding (tooling ) departments with many molds available.

- Professional R&D team,completed quality system.

- Strict Quality-Check Systems.

Product Application:

Transport:

Package and Delivery:

Packed by Carton or Wooden cases.

Delivery:

- Goods in stock can be delivered within 5 days.

- DTH Bits production time is about 15 days.

- DTH Hammer product time is about 30 days.

More products: