F6147 Slurry Pump Impeller Vane

Shijiazhuang Naipu Pump Co., Ltd.- Certification:CE, ISO 9001:2008

- Standard:GB

- Surface Treatment:Spray-Paint

- Manufacturing Process:Casting

- Material:Cast Steel

- MOQ:1 Set

Base Info

- Model NO.:F6147A05

- OEM:Accept

- Color:Yellow, Blue, Red and So on

- Cerificate:ISO 9001 Ce

- Pump Type:Ah Hh M Sp L G Zjq

- Usage:Oil and Gas Transportation Machinery

- Power Type:Electric

- Transmission System:Mechanical

- Transport Package:Packed with Wooden Box or as Customer′s Request

- Specification:CE, ISO, SGS

- Trademark:Naipu Or OEM

- Origin:Shijiazhuang, China

- HS Code:8413709990

- Production Capacity:5000 Set Per Month

Description

Basic Info.

Model NO. F6147A05 OEM Accept Color Yellow, Blue, Red and So on Cerificate ISO 9001 Ce Pump Type Ah Hh M Sp L G Zjq Usage Oil and Gas Transportation Machinery Power Type Electric Transmission System Mechanical Transport Package Packed with Wooden Box or as Customer′s Request Specification CE, ISO, SGS Trademark Naipu Or OEM Origin Shijiazhuang, China HS Code 8413709990 Production Capacity 5000 Set Per MonthProduct Description

F6147 Slurry Pump Impeller VaneShijiazhuang Naipu Pump Co.,Ltd is a professional slurry pumps factory. Our Slurry pump is made up of Frame Plate, Cover Plate,Throat Bush,Cover Plate Liner, Frame Plate Liner, Impeller,Back liner,Expeller Ring,Base, Bearing Housing etc.

Horizontal Slurry Pump Spares-Impeller

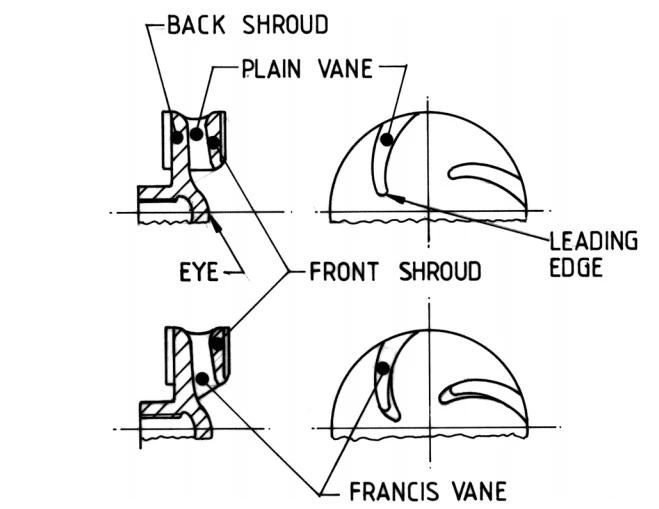

The impeller is the main rotating component which normally has vanes to impart the centrifugal force to the liquid.Usually,slurry pump impellers have a plain or a Francis type vane.

The plain vane has a leading edge square to the back shroud,whereas the Francis vane has a leading edge projecting into the impeller eye.

Some advantage of the Francis vane profile are the higher efficiency,improved suction performance and slightly better wear life in certain types of slurry because the incidence angle to the fluid is more effective.

Slurry Pump spares material

Slurry pump Impeller part code: B1052, B15127, C2127, D3147, E4147, F6147, FAM8147, G8147, G10147, G12147, GAM14147...

1) impeller material: A05,A07,A49,A61,N23 etc.

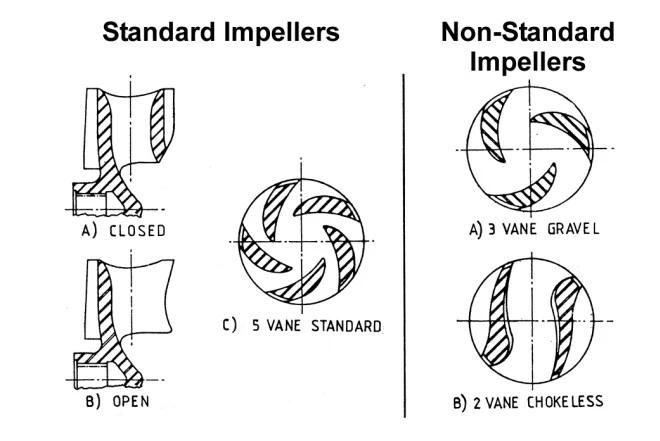

2) There are 3-6 impeller vanes. It depending on the size of the particles in the slurry.

3) Impeller type including Close, Semi-open and Open type. Impellers are generally closed because of higher efficiency and are less prone to wear in the front liner region. Open impellers are more common in smaller pumps or where particle blockage may be a problem or where the shear provided by an open impeller is an aid to pumping froth.

4) We can also produce the non-standard impellers for some special situations.

a)Pumping coarse coal

b)Pumping fibrous material

c)Reduced diameter impellers

d)Reduced eye impellers

Product Overview:

Impeller is the most important part in pump operation,which is a rotor,rotating component of a centrifugal pump.

There are mainly three types of slurry pump impeller: Open,Semi-open and closed.Vanes from 2-6.Front and rear shrouds have pump out vanes that reduce recirculation and seal contamination.When the slurry pump processing the solid mixture,the most worn parts are impellers.

The materials of the impellers are NA05,NA49,NA33,NA61,Natural Rubber,Polyurethane,Ceramic etc.according to different working conditions. Except the standard impellers,we can do OEM and ODM service if client provide us drawings.

Our Part No.

| Basic Part No. | Material Code | Part Name |

| 001 | E62 | Adjusting Screw |

| 003 | G01 | Base |

| 005 | Bearing Assembly | |

| 011 | E62 | Clamp Washer |

| 013 | D20 | Cover Plate |

| 015 | E62 | Cover Plate Bolt |

| 017 | R26A | Cover Plate Liner |

| 018 | R26A | Cover Plate Liner (Half) |

| 024 | E62 | End Cover |

| 028 | G01 | Expeller |

| 029 | G01 | Expeller Ring |

| 029R | R08A | Expeller Ring (Rubber) |

| 032 | D20 | Frame Plate |

| 034 | E62 | Frame Plate Bolt |

| 036 | R26A | Frame Plate Liner |

| 039 | E63 | Frame Plate Stud |

| 041 | A05A,R26A | Frame Plate Liner Insert |

| 043 | R26A | Frame Plate Liner (Half) |

| 044 | K24 | Gland Assembly |

| 060 | R08A | Intake Joint |

| 062 | D70 | Labyrinth |

| 063 | K31 | Lantern Ring |

| 064 | S18 | Impeller O-Ring |

| 067 | E62 | Neck Ring |

| 070 | E05 | Shaft Key |

| 073 | E05 | Shaft |

| 075 | D20 | Shaft Sleeve |

| 076 | D20 | Shaft Sleeve (Long) |

| 078 | G01 | Stuffing Box |

| 081 | E02 | Keeper Plate |

| 083 | A05A,R26A | Throat Bush |

| 085 | E02 | Cotter |

| 090 | S10 | Lip Seal |

| 109 | S18 | Shaft O-Ring |

| 110 | A05A | Volute Liner |

| 111 | Q05 | Packing |

| 117 | E62 | Shaft Spacer |

| 118 | K31 | Lantern Restrictor |

| 118-1 | K24 | Lantern Restrictor(Low Flow) |

| 122 | R11A | Expeller Ring/Stuffing Box Seal |

| 124 | R08A | Volute Liner Seal |

| 125 | R08A | Volute Frame Seal |

| 132 | R08A | Discharge Joint Ring |

| 138 | E62 | Grease Cup Adaptor |

| 179 | C23 | Shaft Sleeve Spacer |

| 210 | S46 | Shaft O-Ring |

| 217 | S18 | Impeller O-Ring |

| 239 | C23 | Impeller Release Collar |

| 241 | K24 | Lip Seal Gland |

| 302 | E02 | Lifting Tube |

| 303 | E02 | Locating Nut |

| 304 | E02 | Volute Lifting Beam |

| 306 | E02 | Shaft Wrench |

| 310 | E02 | Stuffing Box / Expeller Ring |

| 425 | R08A | Dyna Seal |

| 430 | U14 | Nut Covers |

| 005 | Bearing Assembly | |

| 019 | E02 | Mounting Plate |

| 041 | A05A | Back Liner |

| 064 | S18 | Impeller O-Ring |

| 070 | E05 | Shaft Key |

| 092 | A05A | Casing |

| 102 | E02 | Column |

| 116-1 | R10A | Strainer - Upper (Rubber) |

| 116-2 | G01 | Strainer-Upper (Cast Iron) |

| 116-3 | U02A | Strainer-Upper(Urethane) |

| 116-4 | C23 | Strainer-Upper(SS Mesh) |

| 116L | U01A | Strainer-Lower |

| 125 | R08A | Back Liner Seal |

| 154 | E02 | Discharge Pipe |

| 204 | R00 | Discharge Pipe Gasket |

| 231 | E02 | Suction Pipe |

| 290 | E02 | Spacer |

| 293 | E02 | Discharge Pipe Support |

| 306 | E02 | Shaft Wrench |

| 430 | U04A | Nut Covers |

| 005 | Bearing Assembly | |

| 019 | Mounting Plate | |

| 041 | Back Liner | |

| 064 | Impeller O Ring | |

| 070 | Shaft Key | |

| 092 | Casing | |

| 102 | Column | |

| 116 | Strainer-Upper | |

| 116L | Strainer-Lower | |

| 153 | Column Clamp | |

| 154 | Discharge Pipe | |

| 290 | Spacer | |

| 291 | Socket Head Protectors | |

| 293 | Discharge Pipe Support | |

| 306 | Shaft Wrench | |

| 421 | U-Bolt |

Certificate

Naipu Pump have CE,ISO9001:2005 Certificate.

Our Service

1. Quick Reply

Your inquiry related to our products or prices will be replied within 12 hours.

2.Pump Choice .

Please let us know the application, capacity and head ,We can help to select the suitable pump

3.Technical Surport .

We have a group of high quality technicians with rich experience who can solve everything during the whole process.

4.Guarantee quality.

All the products have proved by ISO 9001:2008, CE, SGS. And also will be inspected strictly before delivery. For Comon parts(except wet end parts,) waranty time: 1 years

5.Perfect after -sales .

We will be responsible for the whole life period

6.OEM order. Many materials are available ,like High chrome, rubber , stainless steel and etc.Steely alloy.

Shijiazhuang Headquarters,

No.368 Xinshi North Road,Shijiazhuang,Hebei, China

Contact Person: Karen Tan