Naipu Tl Type A49 Desulphurization Slurry Pump Impeller

Shijiazhuang Naipu Pump Co., Ltd.- Certification:CE, ISO 9001:2008

- Standard:GB

- Surface Treatment:Spray-Paint

- Manufacturing Process:Casting

- Material:Cast Steel

- MOQ:1 Set

Base Info

- Model NO.:TL

- OEM:Accept

- Color:Yellow, Blue, Red and So on

- Cerificate:ISO 9001 Ce

- Pump Type:Ah Hh M Sp L G Zjq

- Usage:Oil and Gas Transportation Machinery

- Power Type:Electric

- Transmission System:Mechanical

- Transport Package:Packed with Wooden Box or as Customer′s Request

- Specification:CE, ISO, SGS

- Trademark:Naipu Or OEM

- Origin:Shijiazhuang, China

- HS Code:8413709990

- Production Capacity:5000 Set Per Month

Description

Basic Info.

Model NO. TL OEM Accept Color Yellow, Blue, Red and So on Cerificate ISO 9001 Ce Pump Type Ah Hh M Sp L G Zjq Usage Oil and Gas Transportation Machinery Power Type Electric Transmission System Mechanical Transport Package Packed with Wooden Box or as Customer′s Request Specification CE, ISO, SGS Trademark Naipu Or OEM Origin Shijiazhuang, China HS Code 8413709990 Production Capacity 5000 Set Per MonthProduct Description

Naipu TL type A49 desulphurization slurry pump impellerDesulphurization Pump Impeller

Shijiazhuang Naipu Pump Co.,Ltd is a professional slurry pumps factory. Our Slurry pump is made up of Frame Plate, Cover Plate,Throat Bush,Cover Plate Liner, Frame Plate Liner, Impeller,Back liner,Expeller Ring,Base, Bearing Housing etc.

Horizontal Slurry Pump Spares-Impeller

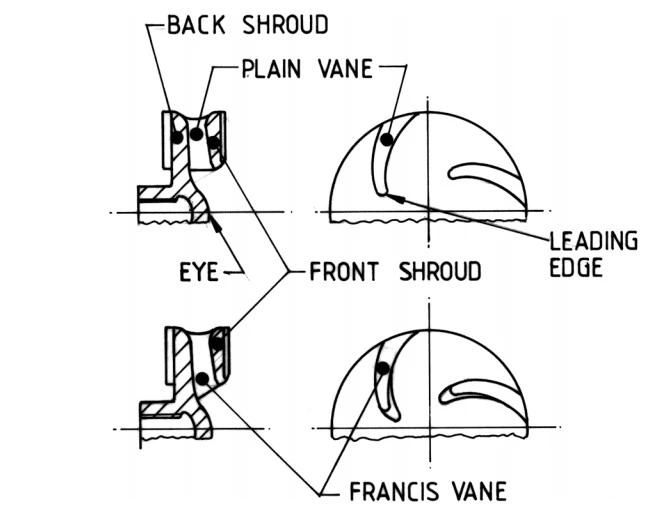

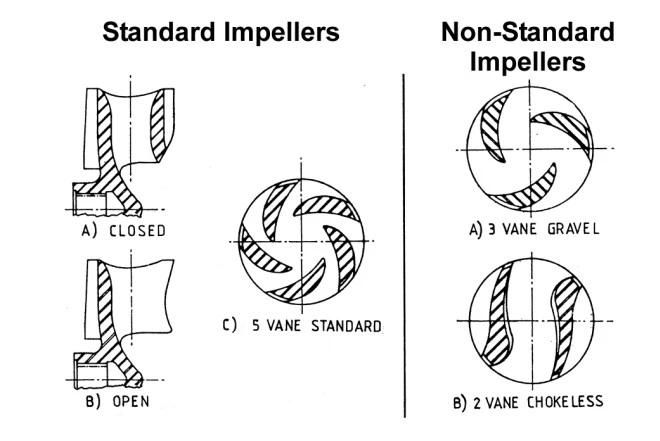

The impeller is the main rotating component which normally has vanes to impart the centrifugal force to the liquid.Usually,slurry pump impellers have a plain or a Francis type vane.

The plain vane has a leading edge square to the back shroud,whereas the Francis vane has a leading edge projecting into the impeller eye.

Some advantage of the Francis vane profile are the higher efficiency,improved suction performance and slightly better wear life in certain types of slurry because the incidence angle to the fluid is more effective.

Slurry Pump spares material

| Impeller Code | Naipu ZJ Slurry Pump | AH Slurry Pump | Materials |

| B1127 | 25ZJ-B | 1.5/1B-AH | High chrome, Natural rubber, Polyurethane |

| B15127 | 40ZJ-B | 2/1.5B-AH | High chrome, Natural rubber, Polyurethane |

| C2147 | 50ZJ-C | 3/2C-AH | High chrome, Natural rubber, Polyurethane |

| C2127 | 50ZJ-C | 3/2C-AH | High chrome, Natural rubber, Polyurethane |

| C2051 | 50ZJ-C | 3/2C-AH | High chrome, Natural rubber, Polyurethane |

| D3147 | 75ZJ-C, 75ZJ-D | 4/3C-AH, 4/3D-AH | High chrome, Natural rubber, Polyurethane |

| D3145HE1 | 75ZJ-C, 75ZJ-D | 4/3C-AH, 4/3D-AH | High chrome, Natural rubber, Polyurethane |

| D3021 | 75ZJ-C, 75ZJ-D | 4/3C-AH, 4/3D-AH | High chrome, Natural rubber, Polyurethane |

| E4147 | 100ZJ-D, 100ZJ-E | 6/4D-AH, 6/4E-AH | High chrome, Natural rubber, Polyurethane |

| E4056 | 100ZJ-D, 100ZJ-E | 6/4D-AH, 6/4E-AH | High chrome, Natural rubber, Polyurethane |

| E4058 | 100ZJ-D, 100ZJ-E | 6/4D-AH, 6/4E-AH | High chrome, Natural rubber, Polyurethane |

| F6147 | 150ZJ-E, 150ZJ-F, 150ZJ-R | 8/6E-AH, 8/6F-AH, 8/6R-AH | High chrome, Natural rubber, Polyurethane |

| F6056 | 150ZJ-E, 150ZJ-F, 150ZJ-R | 8/6E-AH, 8/6F-AH, 8/6R-AH | High chrome, Natural rubber, Polyurethane |

| F6021 | 150ZJ-E, 150ZJ-F, 150ZJ-R | 8/6E-AH, 8/6F-AH, 8/6R-AH | High chrome, Natural rubber, Polyurethane |

| F6058HE1 | 150ZJ-E, 150ZJ-F, 150ZJ-R | 8/6E-AH, 8/6F-AH, 8/6R-AH | High chrome, Natural rubber, Polyurethane |

| FAM8147 | 200ZJ-F | 10/8F-AH | High chrome, Natural rubber, Polyurethane |

| G8147 | 200ZJ-ST | 10/8ST-AH | High chrome, Natural rubber, Polyurethane |

| FAM10147 | 250ZJ-F | 12/10F-AH | High chrome, Natural rubber, Polyurethane |

| G10147 | 250ZJ-ST | 12/10ST-AH | High chrome, Natural rubber, Polyurethane |

| FAM12147 | 300ZJ-F | 14/12F-AH | High chrome, Natural rubber, Polyurethane |

| G12147 | 300ZJ-ST | 14/12ST-AH | High chrome, Natural rubber, Polyurethane |

| GAM14147 | 350ZJ-TU | 16/14TU-AH | High chrome, Natural rubber, Polyurethane |

Metal parts

1. A05 is a wear resistant white iron that offers excellent performance under erosive conditions. The alloy can be effectively used in a wide range of slurry types. The high wear resistance of alloy A05 is provided by the presence of hard carbides within its micro-structure. Alloy A05 is particularly suited to applications where mild corrosion resistance, as well as erosion resistance is required.2.A07 Marten-sic white iron with moderate erosion resistance.

3.A49 is suitable for low pH corrosion duties, where erosive wear is also a problem. The alloy is particularly suitable for Flue Gas Desulphu-rization(FGD) and other corrosive applications, where the pH is less than 4. The alloy can also be used in other mildly acidic environments. A49 has an erosion resistance similar to that of Ni-Hard 1.

Product Overview:

Certificate

Our Service

1. Quick Reply

Your inquiry related to our products or prices will be replied within 12 hours.

2.Pump Choice .

Please let us know the application, capacity and head ,We can help to select the suitable pump

3.Technical Surport .

We have a group of high quality technicians with rich experience who can solve everything during the whole process.

4.Guarantee quality.

All the products have proved by ISO 9001:2008, CE, SGS. And also will be inspected strictly before delivery. For Comon parts(except wet end parts,) waranty time: 1 years

5.Perfect after -sales .

We will be responsible for the whole life period

6.OEM order. Many material are available ,like High chrome, rubber , stainless steel and etc.Steely alloy.

Contact person: Katherine HouShijiazhuang Naipu Pump Co.,Ltd

Shijiazhuang Headquarters,