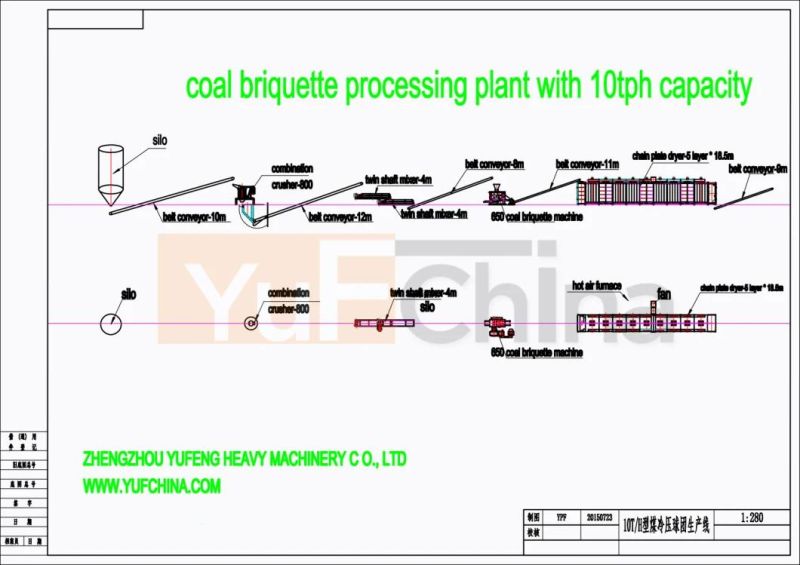

China Factory Supply Ball Press Machine and Briquette Machine

ZHENGZHOU YUFENG HEAVY MACHINERY CO., LTD.- Pressing Mode:Twin-roller

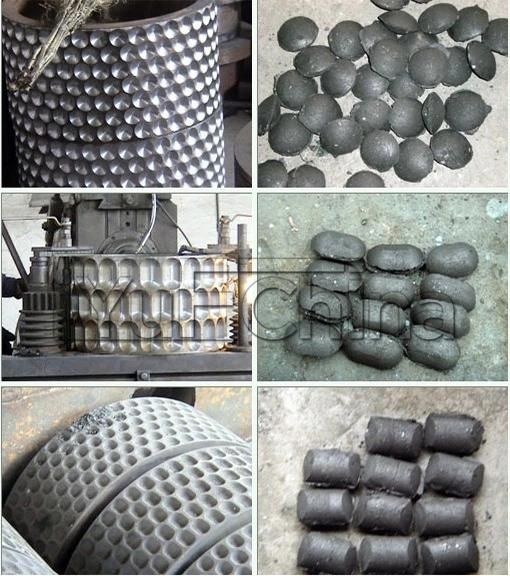

- Product Shape:Ball

- Motor Type:DC Motor

- Condition:New

- Trademark:YUFCHINA

- Origin:Henan China

Base Info

- Model NO.:YQ500

Description

Working principle of charcoal ball press machine

From the storage silo, the material is fed into the molding machine hopper evenly by the quantitative device. Then the regulation board on the hopper make the materal evenly enter into the middle of the roller; the reverse operating roller compress the material and the forming pressure increases gradually, at the centerline of the roll the forming pressure reaches its maximum value, once the material through the line, the molding pressure rapidly decrease so that the material forms into ball shape and smoothly discharge the ball.

Main Features

Main FeaturesUnique structure

Operation cost is low

Smooth rotating speed, high molding rate, and excellent appearance of pressed products.

With greater molding pressure, the quality of the product is significantly improved.

Easy operation

High degree of automation

Briquette making machines can bear high pressure and high strength in working. The mineral powder directly is sent to the smelting furnace with increasing additional value.

Main application range

The high-pressure briquette machine is mainly used to suppress lignite, coal powder, iron powder, coking coal, aluminum powder, iron filings, iron oxide scale, carbon powder, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke powder, etc. Various powders, powders, wastes, and waste residues are widely used in refractory materials, power plants, metallurgy, chemical industry, energy, transportation, heating, and other industries. The materials produced by the ball press machine are energy-saving and environmentally friendly, easy to transport, and improve the The utilization rate of waste has good economic and social benefits.

The piccture details