Coal, Cement, Limestone Stone Crushing Industry Ball Mill for Sale

Xinxiang Great Wall Machinery Co., Ltd.- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:30KW

- Rotationl Speed:20-22r,min

- Application:Mine

- Materials:Ore

Base Info

- Model NO.:Energy-saving ball mill

- Condition:New

- Fineness:3800-4000 Cm²,G

- Application Industry:Cement Plant

- Transport Package:Transport Package

- Specification:11-78 t,h

- Trademark:CHAENG

- Origin:Henan

- Production Capacity:11-78 T,H

Description

Basic Info.

Model NO. Energy-saving ball mill Condition New Fineness 3800-4000 Cm²/G Application Industry Cement Plant Transport Package Transport Package Specification 11-78 t/h Trademark CHAENG Origin Henan Production Capacity 11-78 T/HProduct Description

Introduction of ball millSlag ball mill is a kind of equipment used to grind the slag into powder particles The technical that uses the tube mill on the production of slag has been very mature The slag produced can be used as concrete admixture, reducing the project costs significantly and enhanced the compressive strength, tensile strength, shear strength and bending strength of the concrete Per machine power consumption is :50~80 kWh t

Working principle of ball mill

The energy saving ball mill is a horizontal cylindrical rotating device, which has two compartments. It is energy saving grate ball mill and the outside runs along the gear. The materials enter the first compartment of the mill spirally and evenly through the feeding apparatus and hollow shaft. In the first compartment, there is stepped liner or corrugated liner, and steel balls with different specifications. The centrifugal force generating from the rotation of the cylinder brings steel balls to a certain height, and then the balls fall, thumping and grinding the materials. After coarse grinding in the first compartment, the materials enter the second cabin by single-wall partition. There is flat liner and steel balls in the second compartment, where the materials are ground further. Finally, the powder is discharged through discharge grate and the grinding operation is finished.

Structure characteristics of ball mill

The ball mill mainly consists of feeding part, discharging part, rotary part, drive (reducer, small driving gear, motor, electronic control) etc. The hollow shaft adopts steel castings and the lining can be replaced. The rotary gear is processed with casting hobbing. There is wear-resistant liner in the cylinder and have strong wear resistance. The machine runs stably and has reliable performance.

Advantages of ball mill

- Large double row self-aligning roller bearing with low friction force is used to replace sliding bearing, which is easy to start and saves 20-30% energy.

- Energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore to strengthen the grinding and reduce energy consumption.

- Large outlet port and large capacity.

- The mill with diameter below 2.1 meters adopts whole machine frame, which is convenient for civil construction and equipment installation.

- Oil mist lubrication device guarantees the lubrication of girth gear and pinion.

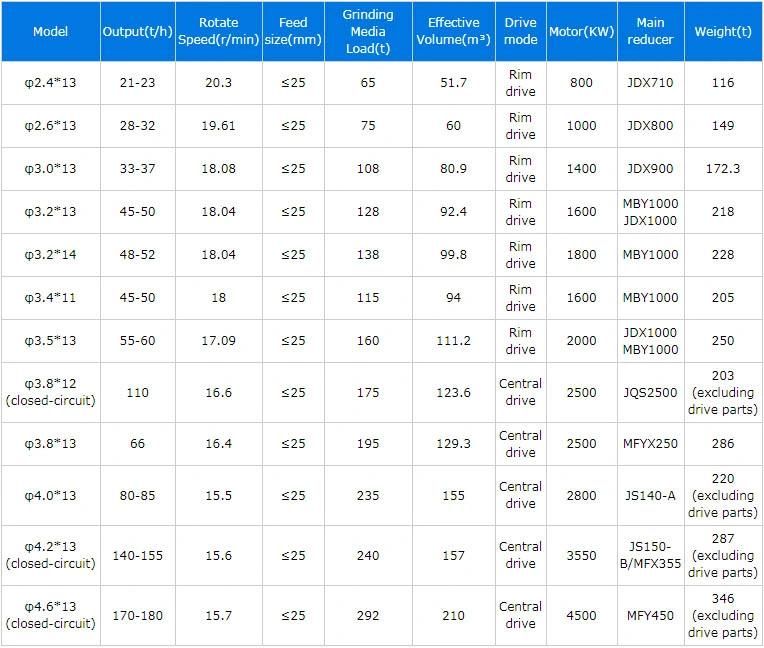

Specification of ball mill

About CHAENG

Founded in 1958 and located in Xinxiang, Henan province, CHAENG with 60-year experience in equipment manufacturing covers an area of 330,000 m2 and its annual production value is 1 billion yuan. The company specializes in manufacturing ball mills, rotary kilns, vertical mills and large steel casting and can undertake the EPC projects of cement production lines, active lime production lines, blast furnace slag/ steel slag/ nickel slag grinding plants, and its products are sold to more than 50 countries and regions in Southeast Asia, Central Asia, South Asia, North America, South America and Europe.

Our long-term strategic partners: Arcelor Mittal, Tata Group, Pohang Iron and Steel Company, Germany CCE, Japan Chiba , Shanghai Baosteel,Voestalpine and ASGT.