Tungsten Carbide Drill Bits Button Bore Well Bit

Myloo Carbide Tool Ltd.- After-sales Service:Online or Site

- Surface Treatment:Polishing

- Manufacturing Process:Sintering

- Material:Tungsten Carbide

- Hardness:90.5 - 91.0hra

- S.T.R.:1800 - 2000MPa

Base Info

- Density:14.90g,cm3

- Grain Size:1.0 - 1.6μm

- Usage:Mining,Quarry,Aggregates

- Experience:18 Years

- Custom-Make:Supported

- Transport Package:Standard

- Specification:MT6Z

- Trademark:Myloo

- Origin:Zigong, China

- HS Code:820900

- Production Capacity:400-500tons,Year

Description

Basic Info.

Density 14.90g/cm3 Grain Size 1.0 - 1.6μm Usage Mining/Quarry/Aggregates Experience 18 Years Custom-Make Supported Transport Package Standard Specification MT6Z Trademark Myloo Origin Zigong, China HS Code 820900 Production Capacity 400-500tons/YearProduct Description

Tungsten Carbide Drill Bits Button bore well bit

OEM &ODM are highly welcomed upon your drawing or sample.

Tungsten has high plasticity, a low rate of evaporation, a high melting point, a strong electron emission ability.

It has the highest melting point of all the elements and melts at 3422ºC.

Why Do Our Carbide Tips Perform Much Better Than The Others?

Except standard grade, we custom-make Grade of the carbide by analyzing customer's local/site working

conditions (e.g. feed size, type, gradation, hardness, screen size, etc).

That means we customize the grade from the first step mixing raw materials, control the temperature and

pressure when sintering, and finally use different welding techniques to make our wear parts suitable for

certain working condition.

Our Factory is located in ZIGONG City(China Tungsten Carbide Production Base), Sichuan Province.

The quality stability of carbide bar is the core for crusher wear parts. How to prolong it's life span is what we

care most.

Our Standard Carbide Grade

Grade: MT6Z

Hardness: 90.5 - 91.0HRA

S.T.R.: 1800 - 2000Mpa

Density: 14.90g/cm3

Grain size: 1.0 - 1.6μm

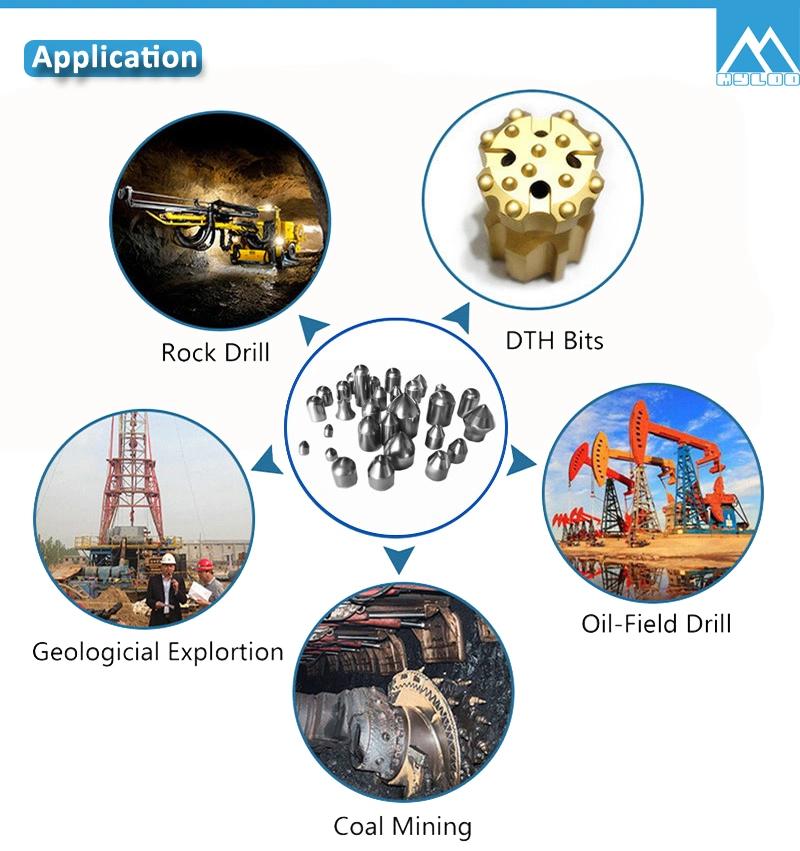

Application:

-For finishing of cast iron and nonferrous metal.-The finishing& semi-finishing of cast iron and nonferrous metals and also for the machining of manganesesteel and hardening steel.-Suitable for the roughing of cast iron and light alloys and also for the milling of cast iron and low-alloy steel.-Suitable for the finishing and semi-finishing of steel and cast steel, and for the milling of steel and cast steel.-Suitable for steel, cast steel, manganese steel, grey cast iron, medium cutting speed and feed rate by half

finishing and semi-finishing end mills.1. for finishing of cast iron and nonferrous metal.-The finishing& semi-finishing of cast iron and nonferrous metals and also for the machining of manganese

steel and hardening steel.-Suitable for the roughing of cast iron and light alloys and also for the milling of cast iron and low-alloy steel.-Suitable for the finishing and semi-finishing of steel and cast steel, and for the milling of steel and cast steel.-Suitable for steel, cast steel, manganese steel, grey cast iron, medium cutting speed and feed rate by half

finishing and semi-finishing end mills.

Q&A:

1. Why You Say Your Tungsten Carbide Tips Have Much Better Performance?

-Coarse enough of grain size to be favorable for welding, especially in cold weather.

- Lower Cobalt without broken, longer wear-resistance.

We never stop finding better grade with much longer wear-resistance to save clients' cost. Now we are testing

new grade with coarse grain size for Europe market, it works well. Also we are making another 3 kinds of new

grade to test and compare with current grade. If it goes well, next step we will try to test it for America market first.

2.How You Control the Quality of The Carbide Tips?

-Much strict control on scrap carbide to ensure stable quality of carbide powder.

All is from qualified carbide rods with grain size 0.8-1.0um, like end mill, reamer, drills. Other carbide

manufacturers usually use carbide drill bits or anvil with grain size 1.2/1.6/2.0 mixed.

-Our special creative sintering process to ensure uniform grain size 2.4um.

Carbide manufacturers usually sinter it by Intermediate Frequency Furnace with temperature 1500ºC, that the

heat-difference can be 70-80ºC causing non-uniform grain size. We use Vacuum Sintering Furnace with "secret"

temperature without heat-difference to ensure uniform grain size 2.4um.

3.Do You Accept OEM&ODM?

Yes, for sure, we can cutomize the grade and shape upon your drawings or samples. Such as, make the grain coarse or add

more cobalt to increase its hardness. Make balance on hardness and toughness.