Chromium Carbide Hardfacing Overlay Wear Plates for Liners

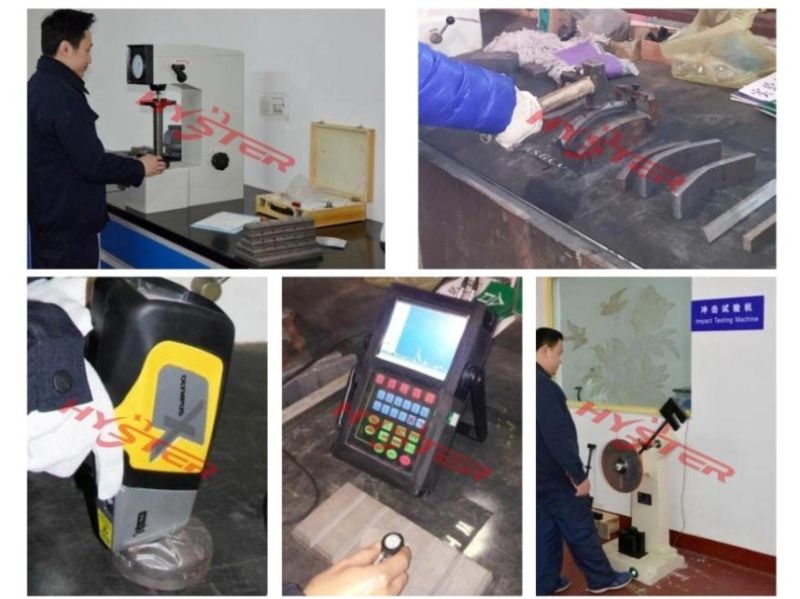

Hunan Hyster Material Technology Co., Ltd.- Certification:ISO 9001:2008

- Standard:ASTM

- Surface Treatment:Shot Blast

- Manufacturing Process:Casting

- Material:Chromium Carbide

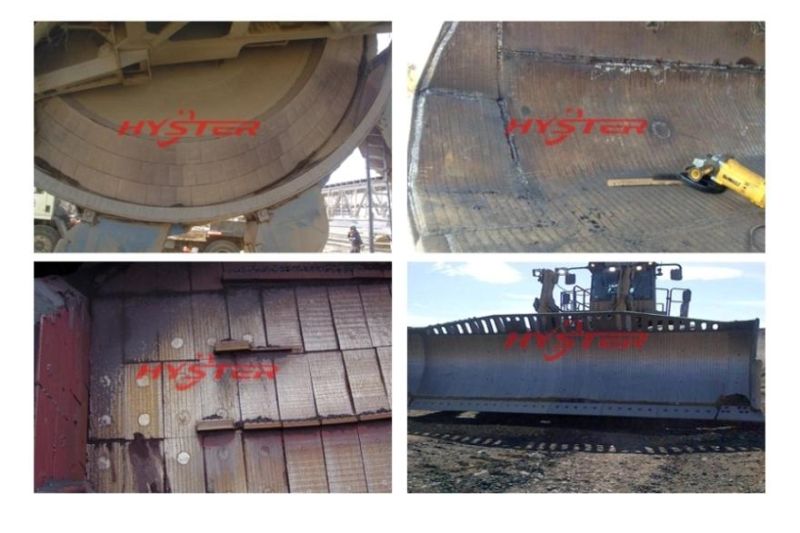

- Application:Ore Mining Wear Protection

Base Info

- Transport Package:Export Crate & Pallet

- Trademark:Hyster

- Origin:China

- Production Capacity:1000 Tons,Year

Description

Basic Info.

Transport Package Export Crate & Pallet Trademark Hyster Origin China Production Capacity 1000 Tons/YearProduct Description

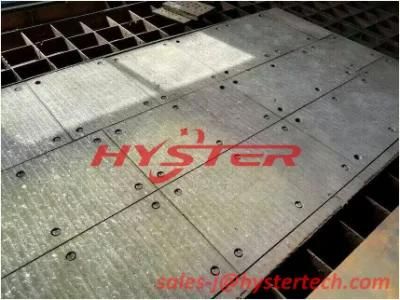

MaterialOverlay Wear Plate is welded by Chromium Carbide overlay on a mild steel backing plate. Manufactured by our independent developed welding machine, Overlay Wear Plate has excellent performance in abrasion resistance.

Chemical Composition

C: ≥3.5%

Cr: ≥23%

Backing plate: Standard SS400 or equivalent stainless steel or other material upon request

Mechanical Property

Hardness: HRC 58~62

Tolerance: ±1mm

Heat Resistance: Max. 350ºC

Microstructure: Mixture of high volume hexagonal shaped Chromium Carbide in tough austenitic and martensitic matrix. Volume Fraction Primary Carbides: 30%

Penetration to the Base Metal: 1.5mm

Cold Forming: Min. Radius: 150mm (for 6+4)

Cutting: Plasma (from backing plate side) / Laser Cutting / Water Jet Knife

Product Series

Chocky Bars Wear Buttons Wear Donuts

Standard Wear Bars Micro-Ledges Wear Plates

Rock Box Liners Skid Wear Bars Shaped Wear Bars

Wafer Strips Grizzly Bars Elbow Wear Bars

Shredder Hammer Tips Knife Edges Overlay Wear Plates

Applications

Ash Liners Elbow Bucket & Lips

Duct Classifier Mine Car Liners

Ore Chutes Slag Chutes Extension Ring

Grizzly Bars Sinter Breaker Bars Green Walt Crushers

Blast Furnace Bell & Burden Sinner Plant Drag Liners

Chute & Hopper Liners Fan Blades & Housings Cyclones

Discharge Funnels Dredge Pump Side Plates Cement Kilns

Vibrator Pan Feeder Liner Conveyor Casings Steel Plant

Specifications of Overlay Wear Plates

| Standard Overlays | Weight Sq/m (kg) | Standard Sheet Size (mm) | Overall Thickness |

| 4 ON 4 | 62 | 1500×3000 / 1200×2400 | 8 |

| 4 ON 6 | 77 | 1500×3000 / 1200×2400 | 10 |

| 6 ON 6 | 92 | 1500×3000 / 1200×2400 | 12 |

| 5 ON 8 | 100 | 1500×3000 / 1200×2400 | 13 |

| 6 ON 8 | 108 | 1500×3000 / 1200×2400 | 14 |

| 5 ON 10 | 116 | 1500×3000 / 1200×2400 | 15 |

| 9 ON 10 | 146 | 1500×3000 / 1200×2400 | 19 |

| 10 ON 10 | 157 | 1500×3000 / 1200×2400 | 20 |

| 12 ON 12 | 162 | 1500×3000 / 1200×2400 | 24 |

| 17 ON 12 | 222 | 1500×3000 / 1200×2400 | 29 |

Hunan Hyster Material Technology Co., LTD.

Founded in 1995, Hyster is a professional manufacturer & exporter of Bi-metallic Wear Blocks & Plates, Wear Pipes, Chocky Bars, Wear Buttons (white iron vacuum brazed onto mild steel, 63HRC/700BHN), Chromium Carbide Overlay Wear Plates, Ni-Hard Castings/Plates, Tungsten Carbide Castings for Mining, Quarrying, and other heavy industries.