OEM High Quality Top Type Cutler Hammer Breakers Excavator 13 Ton Hydraulic Breaker

Shandong Jingyuan New Materials Technology Co., Ltd.- After-sales Service:24 Hours Online

- Warranty:One Year

- Certification:CE

- Surface Treatment:Polishing

- Manufacturing Process:Casting

- Material:Stainless Steel

Base Info

- Model NO.:Breaker

- Name:Hydraulic Breaker

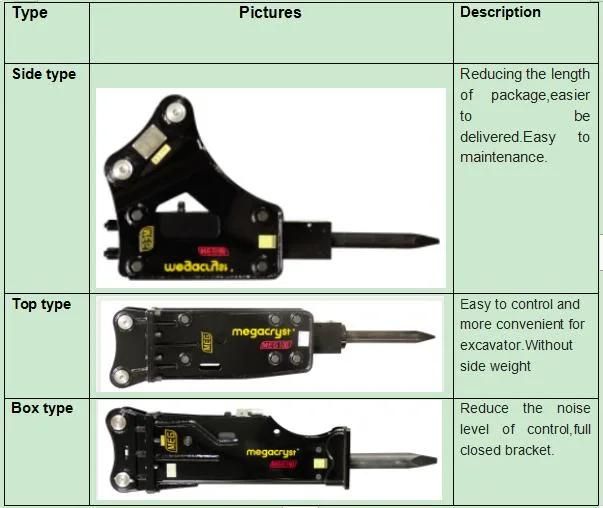

- Type 1:Top Type

- Type 2:Side Type

- Type 3:Box Type

- Colour:OEM

- Transport Package:Wooden Cases

- Specification:2000*1000*1000mm

- Trademark:megacryst

- Origin:China

- HS Code:84122100

- Production Capacity:50000PCS Per Year

Description

Basic Info.

Model NO. Breaker Name Hydraulic Breaker Type 1 Top Type Type 2 Side Type Type 3 Box Type Colour OEM Transport Package Wooden Cases Specification 2000*1000*1000mm Trademark megacryst Origin China HS Code 84122100 Production Capacity 50000PCS Per YearProduct Description

1.Product description:Hydraulic breakers are mainly for construction of roads,bridge and mines,construction of ditchs and asphalt pavements,coal mine,quarry and broken stone,quarry and asphalt pavements.There are lots of kinds,firstly,Soosan type,such as MEG45,MEG53,MEG68 MEG75,MEG85,MEG100,MEG140,MEG155,MEG165,MEG175MEG185,MEG 195...Secondly,Furukawa type,such as 15G,20G,30G,40G...They are mainly for different markets.For the chisels,there are for types to choose.moil.wedge,blunt and cone.They are for different uses.

2.Product types:

3.Specification:

| Contents | Model | MEG40 | MEG45 | MEG53 | MEG68 | MEG75 | MEG85 | MEG100 | MEG125 |

| Body Weight | Kg Ibs | 53 117 | 68 150 | 86 189 | 151 333 | 212 467 | 280 617 | 471 1037 | 618 1361 |

| Total weigh(Side/Top/Slience) | kg | 70/72/102 | 92/92/126 | 155/155/152 | 258/338/356 | 332/407/448 | 557/635/731 | 753/858/999 | 1275/1306/1369 |

| Length(Side) | mm inch | 940 37 | 1053 41.46 | 1170 46.06 | 1415 55.71 | 1480 60.41 | 1735 68.31 | 1994 78.5 | 2285 90 |

| Width (side) | Mm inch | 176 6.93 | 215 8.46 | 229 9.02 | 295 11.61 | 295 11.61 | 412 16.22 | 390 15.35 | 480 18.9 |

| Operating Pressure | Kg/cm² psl bar | 90-120 1280-1700 88-117 | 90-120 1280-1700 88-117 | 90-120 1280-1700 88-117 | 110-140 1562-1988 108-137 | 120-150 1704-2130 118-147 | 130-160 1846-2272 128-157 | 150-170 2130-2414 147-166 | 150-170 2130-2414 147-166 |

| Hydraulic flow range | I/min Gal/min | 15-25 4-7 | 20-30 5-8 | 25-50 6.6-13.2 | 40-70 10.5-18.5 | 50-90 13.1-23.6 | 60-100 15.8-26.3 | 80-110 21.1-29.1 | 90-120 23.7-31.7 |

| Impact frequency | bpm | 800-1400 | 700-1200 | 600-1100 | 500-900 | 400-800 | 400-800 | 350-700 | 350-650 |

| Diameter of hose | mm inch | 12.7 1/2 | 12.7 1/2 | 12.7 1/2 | 12.7 1/2 | 12.7 1/2 | 19.05 3/4 | 19.05 3/4 | 25.4 1 |

| Diameter of Tool | mm inch | 40 1.57 | 45 1.77 | 53 2.08 | 68 2.68 | 75 2.95 | 85 3.35 | 100 3.94 | 125 4.92 |

| Suitable Carrien | ton | 0.8-2.5 | 1.2-3.0 | 2.5-4.5 | 4-7 | 6-9 | 7-14 | 10-15 | 15-18 |

| Contents | Model | MEG135 | MEG135F | MEG140 | MEG140A | MEG150 | MEG155 | MEG165 | MEG175 |

| Body Weight | Kg Ibs | 845 1860 | 858 1888 | 927 2042 | 960 2114 | 1095 2412 | 1305 2874 | 1443 3178 | 1935 4262 |

| Total weigh(Side/Top/Slience) | kg | 1653/1847 /1893 | 1680/1880 /1930 | 1774/2059 /2011 | 1809/2094 /2046 | 2221/2383 /2460 | 2569/2737 /2960 | 2752/3157 /2917 | 3912/4472 /3904 |

| Length(Side) | mm inch | 2367 93.19 | 2367 93.19 | 2414 95.04 | 2414 95.04 | 2519 99.17 | 2367 93.19 | 2816 110.9 | 3176 125.04 |

| Width (side) | Mm inch | 500 19.68 | 500 19.68 | 500 19.68 | 500 19.68 | 590 23.23 | 500 19.68 | 590 23.23 | 670 26.38 |

| Operating Pressure | Kg/cm² psl bar | 160-180 2272-2556 157-176 | 160-180 2272-2556 157-177 | 160-180 2272-2556 157-178 | 160-180 2272-2556 157-179 | 160-180 2272-2556 157-180 | 160-180 2272-2556 157-176 | 160-180 2272-2556 157-182 | 160-180 2272-2556 157-183 |

| Hydraulic flow range | I/min Gal/min | 130-150 34.3-39.6 | 145-180 38.3-47.5 | 120-180 31.7-47.6 | 120-180 31.7-47.6 | 150-190 39.6-50.2 | 130-150 34.3-39.6 | 200-260 52.8-68.69 | 210-290 55.5-76.6 |

| Impact frequency | bpm | 400-800 | 360-460 | 350-500 | 350-500 | 350-700 | 400-800 | 250-400 | 200-350 |

| Diameter of hose | mm inch | 25.4 1 | 25.4 1 | 25.4 1 | 25.4 1 | 25.4 1 | 31.75 1¹/4 | 31.75 1¹/4 | 31.75 1¹/4 |

| Diameter of Tool | mm inch | 135 5.31 | 135 5.31 | 140 5.51 | 140 5.51 | 150 5.91 | 155 5.31 | 165 6.5 | 175 6.5 |

| Suitable Carrien | ton | 18-25 | 18-25 | 18-26 | 18-26 | 27-35 | 18-25 | 30-45 | 30-45 |

4.Chisel type:

| Chisels type | Pictures | Working site |

| Moil type |  | Being applicable to construction of roads,bridge and mines |

| Wedge type |  | Being applicable to construction of ditches and asphalt |

| Blunt type |  | Being applicable to coal mine,quarry and broken stone |

| Cone type |  | Being applicable to quarry and asphalt pavements |

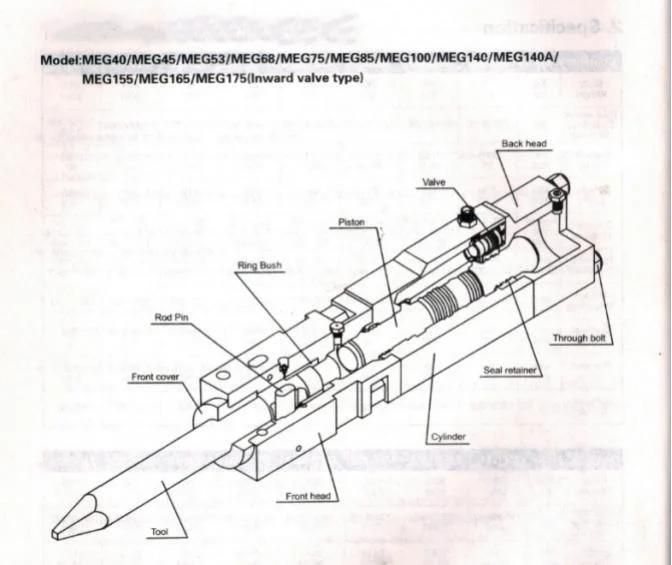

6.Strubture and working principle:

1) Cylinder

1) CylinderThis contains the moving pistion which strikes the tool. The seals for both ends of the piston are also located in the cylinder. The seals for the upper end of the piston are located in a removable seal retainer while the seals for the lower end of the pasion are located in provers machined directly into the cylinder.

2) Piston

The piston transfers impact power to the tool. generated by hydraulic power.

3) Seal retainer

The seal retainer has oil seals th seal Nitrogen(N2) gas in back head, and to prevent hydraulic oil leakage.

4) Valve

The valve controls reciprocates piston action with hydraulic fluid distribution.

5) Front head assembly

This retains the tool, using the tool pins.By removing these pins, the tool can be changed.

6) Ring Bush

This guides the tool,Ring Bush limits the uppermost position of the toolIt is consumable parts,which should be checked for wear limits. If needed,they should be repalced.

7) Tool

This transfer piston ompact power to the objects.We recommend that various tool shaps according to working circumstance.

8) Rod Pin

This is installed on the front head, and prevents the tool from coming off.

9) Back head assembly

This contains the cushion chamber charged with nitrogen(N) gas that is compressed during upward strokes of the piston, and serves to provide maximum absorption of piston recoil, effciency storing this energy for the next blow

10) Through bolts

These are used to assemble the front head, the cylinder and the back head. They have to be constantly tightened to specified torque. Inspect the bolts for loosening, and re-tighten them weekly.

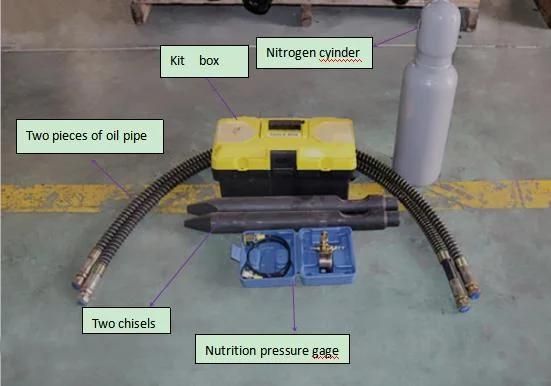

7.Spare parts for free with the breaker and the Packing

8.Product line:

9.Our Exhibition:

9.Our Exhibition:

10.Our certificate:

11.COMPANY BRIEFS:

11.COMPANY BRIEFS:

Shandong Jingyuan New Materials Technology Co.,Ltd,established in 2000,is mainly engaged in research and development of rubber floor,rubber track and PU binder.After the development of 17 years,the company enjoys good reputation in industry and the products are popular in domestic and foreign markets.In 2011,the company bought a large number of advanced equipments and absorbed a large number of outstanding staff to build a new factory supplying hydraulic hammers and related parts.

We are a top ranked led lighting products exporter, and has customers in over 60 countries throught the Europe, Asia, South America, Latin America and Middle East. We are committed to creating outstanding products backed by friendly, responsible excellent service to delight our esteemed loyal customers around the world.With best service.With your trust and support,the company will become stronger and can meet your demands better.

12.Company Advantages:

1. Big production capacity, fast delivery.

2. Strict QC inspecting rules: all products must be 100% inspected before delivery.

3. OEM/ODM services are available

4. 24 hours online service.

5. Prompt quotation for your inquiry

6. Quality,reliability and long product life.

7. Professional manufacturer offers competitive price.

8. Diversified rich experienced skilled workers.

13.FAQ:

Q1: Are you a factory or trading company? Where is your company located?

A1: We are a factory 100%, not trading company. Our company is located in Weifang, Shandong Province,China

Q2: What is the warranty for our lamps?

A2: We have 3 years warranty for our lamps

Q3: How do you ensure the quality

A3: We are working with four QC processes to guaranty the quality: 1 .For raw materials; 2. During the half of production; 3.Final test before delivery; 4. Selects inspection of the packaged products

Q4: How to do if any quality problems from our reason in the warranty time?

A4: First, take pictures or videos as proof and send to us, and then we will replace new ones for free.

Q5: OEM OR ODM accepted?

A5: Yes, we can do OEM & ODM, logo on the breaker or package both is available.

Q6: Can we get support if we have our own market position?

A6: Please inform us your detailed market demand, we will discuss and propose helpful suggestion for you, to find the best solution for you.

Q7: What's your MOQ? Can I order small quantity for testing at first order?

A7: For new client, we accept small order for building mutual trust and long-term business relationship.

Q8: What is your shipping method suggested?

A8: Small package via courier such as DHL,Fedex,UPS,EMS; Bigger package by Air shipment; Big package via Vessel.

Q9: How many days will samples be finished? And how about the mass production?

A9: Generally 7-15 days for samples making. The leading time of mass production will depend on the quantity.

Q10. What's the payment method you accept?

A10: T/T, Western union.

Q11: Can i visit your company?

Welcome to visit our factory and it is our great pleasure