Mineral Plant Silicon Manganese Ore Crusher

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Type:Impact Crusher

- Motor Type:AC Motor

- Motor Power:37kw

- Application:Construction

- Materials:Limestone, Dolomite, Shale, Sandst

- Outlet Size:0-25mm

Base Info

- Model NO.:PF

- Inlet Size:1000*700mm

- Condition:New

- Name:Mineral Plant Silicon Manganese Ore Crusher

- Warranty:12 Months

- Model:PF-1007

- Rotor Size:1000*700

- Certification:ISO9001:2015 Ce

- Max Input Size:350mm

- Capacity:15-30 T,H

- Feature:Long Life

- Payment:L,C or T,T

- Weight:5-6t

- Transport Package:Standard Export Packing

- Specification:crushing machine

- Trademark:HENGCHANG

- Origin:China

- HS Code:8474209000

- Production Capacity:100 Sets,Month

Description

Basic Info.

Model NO. PF Inlet Size 1000*700mm Condition New Name Mineral Plant Silicon Manganese Ore Crusher Warranty 12 Months Model PF-1007 Rotor Size 1000*700 Certification ISO9001:2015 Ce Max Input Size 350mm Capacity 15-30 T/H Feature Long Life Payment L/C or T/T Weight 5-6t Transport Package Standard Export Packing Specification crushing machine Trademark HENGCHANG Origin China HS Code 8474209000 Production Capacity 100 Sets/MonthProduct Description

1. Brief Introduction of Mineral Plant Silicon Manganese Ore CrusherImpact Crusher is widely applied in metallurgy, mining, cement, chemical, refractory, highway constructions, water conservancy projects, building waste and sand processing, etc., for the secondary crushing and fine crushing of medium hardness brittle materials such as limestone, dolomite, shale, sandstone, coal, asbestos, graphite, feldspar, quartz, calcite cement, rock salt and other ore-bearing stones, etc.

Modern mining industry needs high crushing ratio crushers, Hengchang new designed PF series impact crushers can meet this particular requirement. It is very common that mining equipment are frequently broken after a long-term use, so our engineering team adopt advanced techniques to make our impact crushers more suitable. If you want to use efficient impact crusher, our PE impact crusher is a smart choice.

2. Main advantages of Mineral Plant Silicon Manganese Ore Crusher

1). High crushing ratio (usually 10%-20%, and maximum 50%-60%).

2). Automatic open-top device.

3). Hydraulic jacking device and hydraulic regulated discharging port.

4). High carrying capacity.

5). Reformative adjusting device.

6). Unique structure & simplified crushing process: convenient for maintaining and operation.

7). High-end fabrication material, so it can work long time.

8). Uniform and nice particle shape/size.

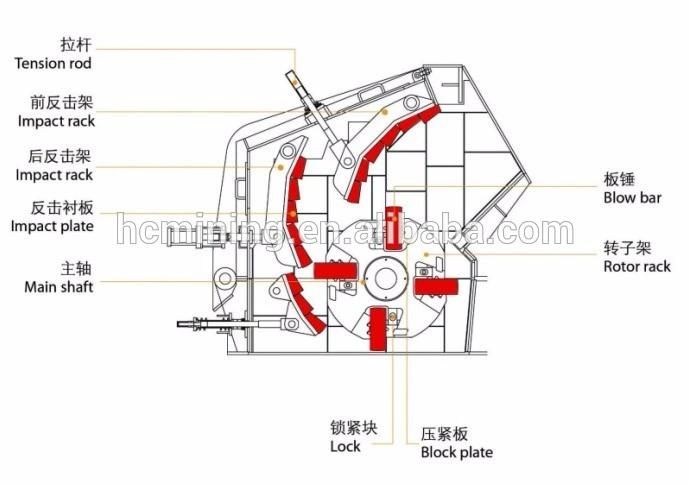

3. Working principle of Mineral Plant Silicon Manganese Ore Crusher

Impact breakers/Impact crushers crush materials with impact force. When PF impact crusher works, materials are crushed by the high-speed impact of the blow bar after they enter the cavity, they will be fed into the impact plates for secondary crushing, then the materials will be shot back to the blow bar again for the third crushing. This movement repeats until the materials are crushed to prospected particle size and finally will discharged from discharging opening. The size and shape of the finished material can be changed by adjusting the gap between the impact rack and rotor support.

Compare to other crushers, our impact crusher has bigger reduction ratio and can fully use the high speed impactenergy of entire rotor.

The ideal entering material granularity of our PF type impact crusher is 100-500mm, the most greatly is not surpass the rating. Users can adjust the hammer head and the impact board and the gap between components according to different requirments on materials granularity.

4. Technical Parameters of Mineral Plant Silicon Manganese Ore Crusher

| Model | Rotor size | Max.input size | Output size | Motor power | Capacity | Weight |

| mm | mm | mm | kw | t/h | kg | |

| PF-0807 | Φ850 x 700 | 300 | ≤25mm accounts for 85% | 30 | 10-25 | 3500 |

| PF-1007 | Φ1000 x 700 | 300 | ≤25mm accounts for 85% | 37 | 15-30 | 6500 |

| PF-1010 | Φ1000 x 1050 | 350 | ≤25mm accounts for 85% | 55-75 | 50-80 | 12100 |

| PF-1210 | Φ1250 x 1050 | 350 | ≤25mm accounts for 85% | 110-132 | 70-120 | 14000 |

| PF-1214 | Φ1250 x 1400 | 400 | ≤25mm accounts for 85% | 132-160 | 130-180 | 18500 |

| PF-1315 | Φ1300 x 1500 | 500 | ≤25mm accounts for 85% | 160-200 | 180-260 | 23500 |

| PF-1320 | Φ1320 x 2000 | 500 | ≤25mm accounts for 85% | 300-350 | 300-350 | 26500 |

5. Pre-sale service:

Freely provide project designing, process designing, select suitable equipment for you.

6. Order execution service:

Provide equipment layout draw, foundation draw and detail equipment manauls. Timely report you the manufacturing schedule and related photos for keep monitoring.

7.. After-sales service:

Dispatch engineer to the site to guide installation, debugging and training operators. Installation and operation workers are offered if you need.

8. Our company

Gongyi Hengchang Metallurgy Building Material Equipments plant is a professional manufacturer specializing in the production of mineral beneficiation equipments, sand and stone crushing equipments, briquetting equipments, coal preparation equipments, drying and calcining equipments, cement plant equipments and compound fertilizer equipments.

9.Contact us

If you want to know more details, please contact me!!

Website:http://hcmining.en.made-in-china.com

Tel: +86-0371-86160152

Amanda