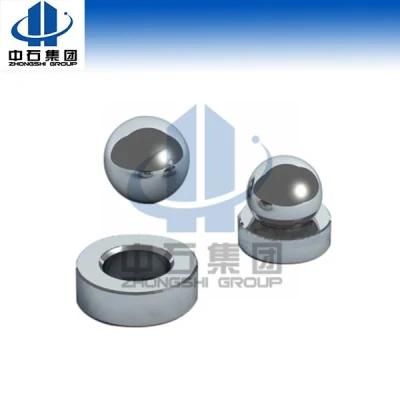

Stellite Valve Balls and Seats for Sucker Rod Pump

Puyang Zhongshi Group Co., Ltd.- Material 1:Stellite

- Material 2:Tungsten Carbide

- Material 3:Stainless Steel

- Material 4:Titanium Carbide

- Certificate:API 11ax

- ODM:Avaialble

Base Info

- Model NO.:API V11-225, API V11-175,API V11-150,V11-250

- Sample:Available

- Drawing:Available

- Transport Package:Wood Package

- Specification:V11-125,V11-175,V11-225,V11-250

- Trademark:zhongshi

- Origin:Henan, China

- HS Code:843143100

- Production Capacity:50000PCS,Year

Description

API No.

Seat Size

Ball Size

V11-106

2"

1-1/4"

V11-225

2-3/4"

1-1/16"

V11-375

3-3/4"

2-1/4"

Features:

1) Castings of main alloys: cobalt-base alloy, nickel -base alloy and stellite alloy

2) Available forms: end product or blank

3) Properties: good resistance against corrosion and oxidation

4) Main application: extensively used in petrochemical industry, marine exploration, heat exchanger and pump

5) Processing: investment casting, sand casting

Materials for Balls and Seats

Symbol

Symbol

Hardness

Material

A1

Stainless Steel

Ball: HRC 58-65

Seat: HRC 52-56

UNS 41000-UNS 44000

B1

Cobalt Alloy, Cast

Ball: HRC 56-63

Seat: HRC 50-56

Cobalt, chromium, and

tungsten alloy

B2

Cobalt Alloy, Powder

Metal

Ball: HRC 53-60

Seat: HRC 51-57

Cobalt, chromium, and

tungsten alloy

C1

Tungsten Carbide

Ball: HRA 88-89

Seat: HRA 88-89.5

Tungsten with Cobalt

binder

C3

Titanium Carbide

Ball: HRA 89-90.5

Seat: HRA 89-90.5

Tungsten and titanium carbide

with cobalt binder

stellite valve seat

1. High strength, high wear resistance, high precision, good temperature resistance and good corrosion resistance.

2. Mainly used for the sealing of valves of oil pumps in petroleum industry's containing wells, viscous oil wells, sea oil wells and high pressure sulfur resistant oil wells, etc.

3. Balls and seats are used with compatible cemented carbide valve seats.

4. The finished surface, tolerance standard have reached the standards of the machine industry: G5, G10, G16, G40 and G100 of JB/T 9145-1999.

5. Precision machined cemented carbide balls of other grades and specifications are also available based on customers` demands.

6. Compatible high precision valve seats can also be made.