Dr580 Drill Bits Drilling Tools Apply to Sandvik Drilling Machine Parts

Maanshan City Hyton Heavy Industry Technology Development Co., Ltd.- Certification:CE, ISO 9001:2008

- Standard:ASTM

- Surface Treatment:Polishing

- Manufacturing Process:Casting

- Material:Cast Steel

- Transport Package:Standard Packing

Base Info

- Specification:standard size

- Trademark:Hyton

- Origin:Maanshan China

- HS Code:84749000

- Production Capacity:300 PCS Per Year

Description

Basic Info.

Specification standard size Trademark Hyton Origin Maanshan China HS Code 84749000 Production Capacity 300 PCS Per YearProduct Description

DR580 Drill Bits Drilling Tools Apply To Sandvik Drilling Machine parts

The rock drill works according to the principle of impact crushing. When working, the piston makes high frequency reciprocating motion and continuously impacts the brazing tail. Under the action of impact force, the rock is crushed and drilled into a certain depth by a sharp wedge-shaped bit, forming a dent. When the piston retreats, the braze rotates at a certain angle, the piston moves forward, and when the brazing tail is impacted again, a new dent is formed. The fan-shaped rock blocks between the two notches are sheared by the horizontal force generated on the bit. The piston continuously impacts the drill tail and continuously inputs compressed air or pressure water from the central hole of the drill to discharge the slag out of the hole, which forms a circular drill hole with a certain depth.

Hyton's Drill Rock Tools can be perfectly matched with the world famous brand such as Atlas Copco, Sandvik, Ingersoll-Rand and other well-known manufacturers′ Drill rigs and they are widely applied to varies of areas including blast holes, earthwork projects, mineral exploration, water-well, construction, geo-thermal exploration,mainly include : DTH Hammer , DTH Bit , Drill Rod , Taper Button Bit , Thread Button Bit , Shank Adapter and etc .

Generally, the light duty rock drill usually use 7 taper or smaller taper angle, the heavy duty rock drill mainly use 11, 12 taper angle.

Tapered button bits

- Type: Tapered button bits

- Size: Hex.19mm, 22mm, 25mm

- Diameter: 30-45mm.

- Taper: degree 4°46′ 6°, 7°, 11°, 12°

- Package: in wooden case or in carton.

- Productivity: 10000pcs/ month

Our tapered bits include both cross and button designs.

11°, 12° Taper button bit with hot zinc-coating

Tapered drill rod

Steel grade: Sandbar 64 or Sandbar 20 or C253, 55SiMnMo

Size: Hex.22mm, Hex.25mm

Taper: 4°46′, 6°, 7°, 11°, 12°.

Length: 0.4m-10m

Package: in wooden case or in bundles.

Productivity: 20000MT / month

Main Features :

1.20 years experience ,all parts can suit the crusher well.

2.Hyton guarantee the 100% replace the original parts.

3.Certified by ISO system certification .

4. Large amount of stock for customer with competitive price.

5. OEM service available.

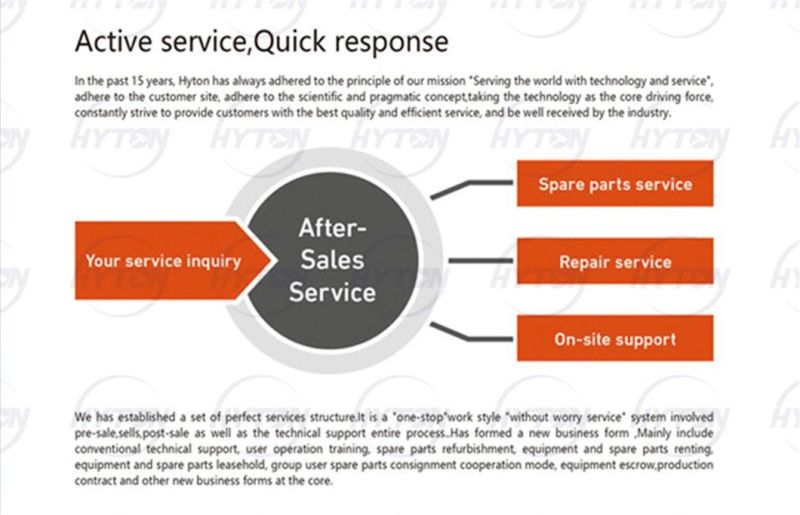

Hyton's Guarantee to all of our customers :

All of the castings finish must go along with the Metal Inspection and Dimension Inspection .

Hyton will always have the responsibility of all the products from hyton in the market , will service a "24+3"service rules (After get the request from customer , The after-service department of hyton myst supply the feedback solution within 24 hours ,and must get Consistent scheme amd solve the promblem within 3 days .

Hyton have a professional after-service team can promise service all over the world ,service including the Installation Guide ,Measurement at site ,Inspection and etc .

After goods packaged well , we need only 1 day ship good to shanghai port ,which means that most of the spare parts you bought from Hyton ,it will get your port within 30 days all around the world if ship by sea.