Dewatering Vibrating Screen Cyclone Separator Spiral Separator Machine

Zhengzhou Zhongjia Heavy Industry Co., Ltd.- Type:Spiral Sand Washer

- Capacity:50-75t,h

- Water Consumption:20-150t,h

- Speed of Screw:38rpm

- Motor Type:AC Motor

- Motor Power:47kw

Base Info

- Model NO.:lx

- Certification:ISO

- Rotation Speed:38rpm

- Screw Diameter:750mm

- Warranty:12 Month After Installation

- After-sales Service:Installation Guide, Spare Part Supplying

- Application:Sand Washer

- Transport Package:Container

- Specification:ZKR1236

- Origin:Henan China

- HS Code:8474100000

- Production Capacity:60 Set,Year

Description

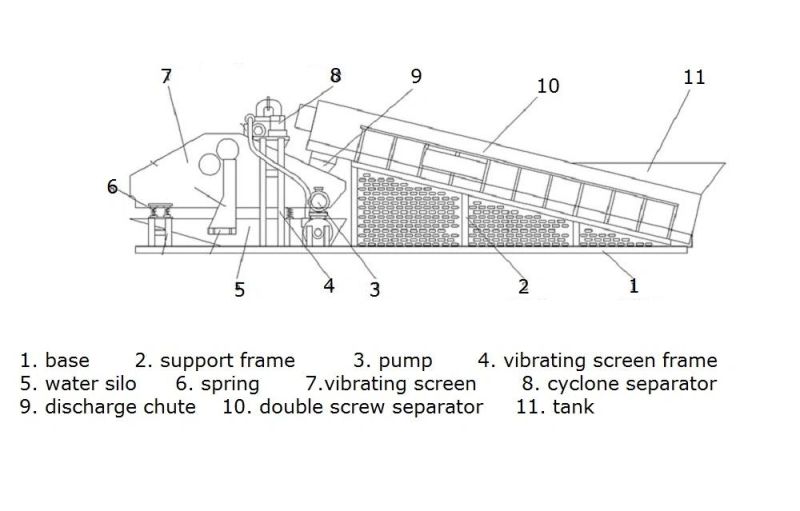

Spiral screen washing machine is an integrated equipment with small floor area, simple operation, large processing capacity and good cleaning effect. Spiral sand washing machine is a multifunctional water sand washing equipment integrating the functions of water sand washing, sand and gravel material dehydration and recovery. The equipment is composed of spiral sand washing machine, dehydration screen and cyclone.

The material is first sent to the inside of the washing box of the spiral sand washer, and the material is pushed to the front end of the discharge port through the blades in the double spiral sand washer, washed with water in the middle, and then passed through the discharge port. The double spiral sand washing machine is a spiral cleaning equipment that uses the spiral principle to push sand and gravel to separate it from water and soil. The other end is equipped with dry tailings discharge. The internal materials fall on the dry tailings discharge. The single-direction excitation force generated by the exciter on the tailings dry discharge screen causes the screen box to move in a reciprocating linear motion. The water falls into the falling water tank through the screen. The falling water tank and the spiral sand washer cleaning tank are connected by pipes. The feed port of the cyclone and the falling water tank are connected by pipes and slurry pumps. The water tank is mostly coarse due to centrifugal sedimentation. The sand particles are discharged through the bottom outflow port of the cyclone, and most of the fine particles are discharged from the overflow pipe to achieve the purpose of separation. The sand settling nozzle of the cyclone is located above the dry tailings screen to form the concentrated material drop of the cyclone. In the structure of dry tailings discharge, the water separated by the cyclone flows into the recovery tank, and the water inside the recovery tank flows into the washing tank of the spiral sand washer, thereby completing the cleaning, grading and dehydration of the materials.

Dewatering screen product overview

| Model | Feed size (mm) | Screw diameter (mm) | Tank length (mm) | Screen size (mm) | Cyclone | Water QTY (m3/h) | Sand QTY (t/h) | Power (kw) | Weight (t) |

| LX09-65-1530J | ≤10 | 920 | 8000 | 1500x3000 | FX300x2 | ≤150 | 50-80 | 47 | 8480 |

| LX09-75-1836D | ≤10 | 920 | 8000 | 1800*3600 | FX350*2 | ≤200 | 60-100 | 56 | 10140 |

| 2LX09-100-2442J | ≤10 | 920 | 8000 | 2400*4200 | FX250*4 | ≤240 | 150-180 | 81 | 16950 |

Service and customers

With the tenet of "Quality First, Customers First", our company specially invites experts from design colleges and universities for technical cooperation, and can provide users with project design, ore identification, small test, and One-stop service including testing, equipment selection, process design, equipment site installation and commissioning. It has provided high-quality equipment for large domestic large-scale concentrators, metal magnesium plants, steel plants and other large-scale projects, is trusted and praised by users serving Panzhihua Iron and Steel, Kunshan Iron and Steel, China Aluminum Group, Three Gorges Water Conservancy and other national key construction projects and thousands of private enterprises.