Weighing Feeder

Blackstone International Company Limited- Type:Feeder

- Voltage:220,380,440

- Weight:<1T

- Material:Carbon Steel

- Material Feature:Fire Resistant

- Certification:ISO9001:2000

Base Info

- Model NO.:Weighing feeder

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Multi Color

- Customized:Customized

- Condition:New

- Transport Package:Naked

- Specification:Standard seaworthy packing

- Trademark:OEM

- Origin:China

- HS Code:8479820090

- Production Capacity:100 Pieces Per Month

Description

Basic Info.

Model NO. Weighing feeder Energy Saving Energy Saving Warranty 1 Year Color Multi Color Customized Customized Condition New Transport Package Naked Specification Standard seaworthy packing Trademark OEM Origin China HS Code 8479820090 Production Capacity 100 Pieces Per MonthProduct Description

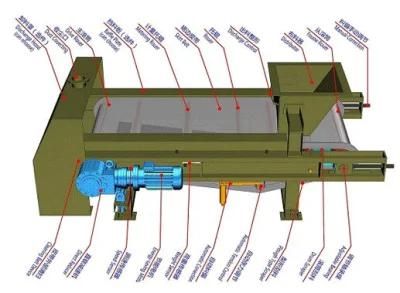

Weighing feeder

[Introduction] An automatic quantitative feeding equipment.

[Capability] 1-6000 TPH

[Application] It can be widely used in ferrous metal, non-ferrous metal and non-metallic mineral processing plants.

Advantages

Accurate measurement

Because the material is transmitted to the load sensor through the belt, the characteristics of the belt will affect the force of the load sensor, thus affecting the measurement accuracy. Through the belt dynamic monitoring sensor, combined with the software to compensate the impact of the belt on the load sensor, the purpose of improving the measurement accuracy is achieved.

Measurement is more stableThe distance of metering section is lengthened, the time of force acting on material is lengthened, which is more conducive to metering and improves the stability of metering, and fundamentally solves the influence of material unbalanced load on metering.

Structure

The metering pump is the main feeding equipment of NC Reagent Feeder. It assembles the dosing box, mixer, level gauge, safety valve, check valve, pressure gauge, filter, buffer, pipeline, valve, base, escalator, automatic monitoring system and power control system on a common platform according to the technological process, forming a module, that is, the so-called skid-mounted combined unit.

Technical Parameter

Model | Accuracy % | Feeding Capacity tph | Inclination Angle | Number of weighing sensors | Number of weighing idlers |

ICS-14A | ±0.125 | 1-6000 | ≤6° | 4 | 4 |

ICS-17A | ±0.25 | 1-6000 | ≤17° | 2 | 4 |

ICS-17B | ±0.25 | 1-6000 | ≤17° | 2 | 2 |

ICS-20A | ±0.5 | 1-4000 | ≤17° | 1 | 2 |

ICS-20B | ±1.0 | 1-4000 | ≤17° | 2 | 1 |

ICS-30A | ±0.25 | 1-4000 | ≤17° | 2 | 1 |