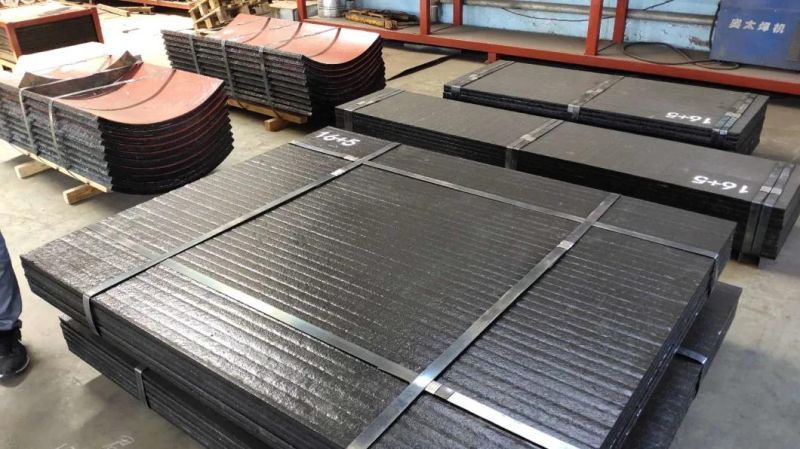

High Chromium Alloy Hardfacing Plate

JINAN LIT INDUSTRY CO., LTD.- Certification:CE, ISO 9001:2000, ISO 9001:2008

- Standard:AISI, ASTM, DIN

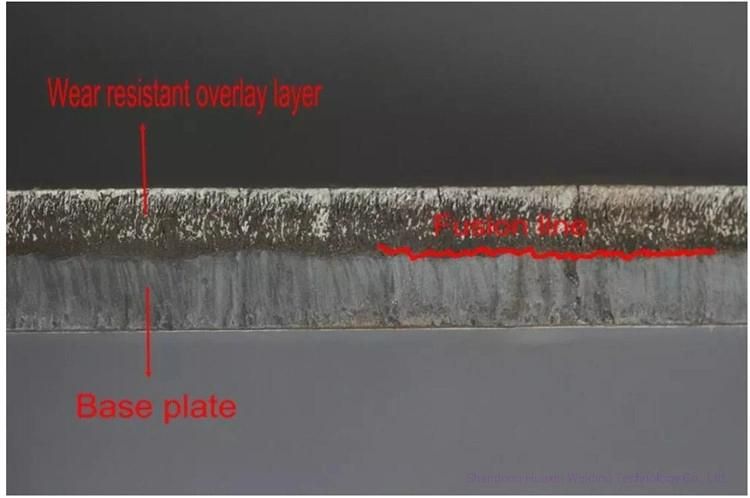

- Surface Treatment:Hardfacing, Cladding, Coated, Chromium Carbide

- Manufacturing Process:Overlay Welding

- Material:Alloy Steel

- Hardness:HRC58-65

Base Info

- Microstructure:Carbide (Cr7c3)Volume Fraction Above 50%

- Base Metal:Q235 or Q345

- Coated Layer Surface:Smooth, No Obvious Roughness

- Transport Package:Seawhorthy

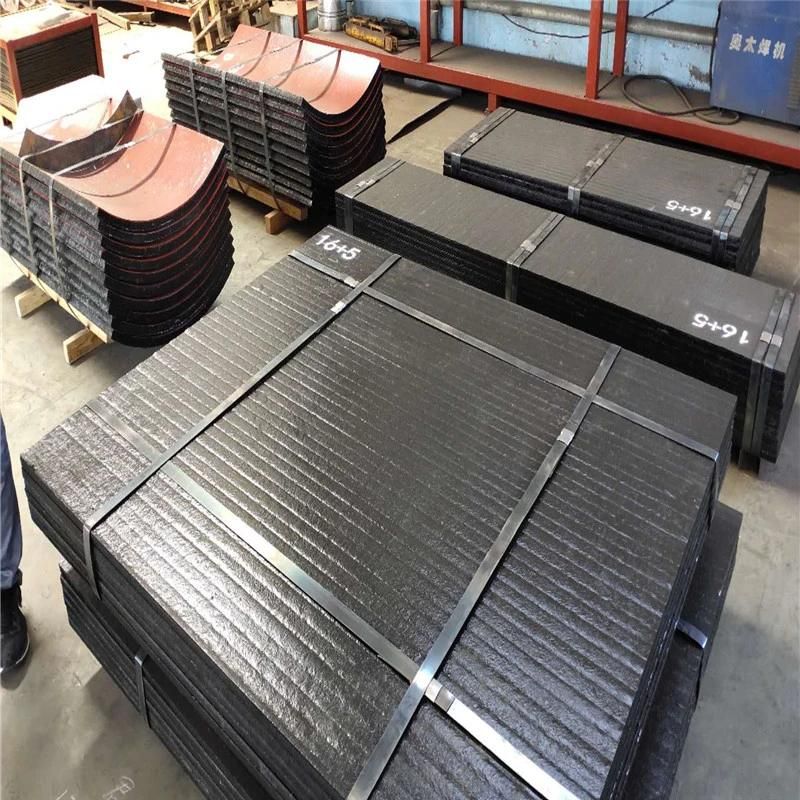

- Specification:3+3,4+4,5+5,6+4,6+5,6+6,8+4,8+5,8+8,10+10,12+12,16

- Trademark:HUAXIN

- Origin:China

- HS Code:72109000

- Production Capacity:10000tonne,Year

Description

High chromium alloy hardfacing plate

Hardness

Wear deposite 3mm: HRC 52-58, 4mm: HRC 56-60 ,5mm: HRC 58-62,

6mm: HRC 58-62, 8mm: HRC 58-62, 10mm: HRC 60-62, 12mm: HRC 60-63

C : 4.3-4.8% Cr : 23-30% Mn : 0.8-1.1% Mo: 0.08-0.18 Ni:0.08-0.15

Other Metal elements : Micro

Feature

12-20 times higher than common plate

5-10 times than low alloy steel plate

2-3 times than high chromium cast iron plate

Our Advantages:

Extend service life and improve efficiency of the equipment.

Reduce maintenance cost and time.

Reduce working intensity of service department

Reduce overall cost.

Applicant: Conveyors, Crushers, Skirtboards, Chutes, Hoppers, Feeders, Haul Truck Bed Liners, Screens

Hardness ranges from 58-62 HRC based on weld thicknes

Advantage Features:

1) High wear performance: the property of wear resistance is much higher than the heat resistant steel and casting wear-resistant cast iron, abrasion resistance is also significantly higher than the wearing layer that relying on spray welding or thermal spraying to produce.

2) Strong Shock Resistance: strong shock resistance and crack resistance, that suitable for vibration, hard shock working conditions.

3) Easy Processing: made in standard sizes, which had light weight, convenient and flexible processing.

4) Better Cost Performance: a better cost performance 2-3 times than ordinary materials, the per unit area cost only the a half of using the same kind of ingredients by hand electrode surfacing.

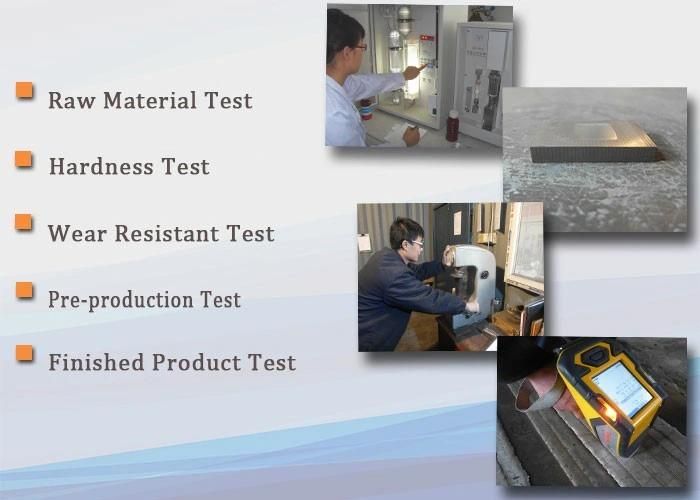

Strict Quality Control: No matter what thickness of the wear plates, the wear resistant layers are uniformly straight. Could be processed the wear resistant composite plates with thinness of 4mm (2mm +2 mm).

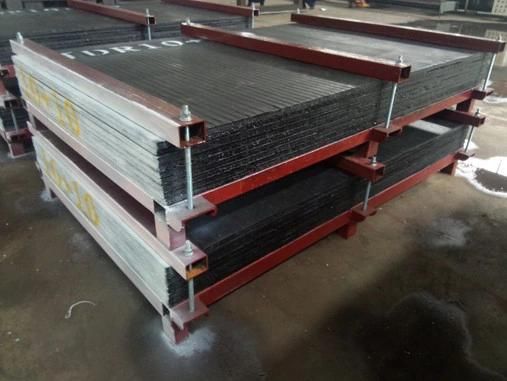

Package&Shipment:

Wear plates are packed in seawhorthy wooden boxes/angle iron frame or customized package.

Q: Why choose us?

A: We are one leading professinal company with over 13 years experiences of wear resistant plate design and operation, provide personalized processing services.

Q: Can you send the sample to the buyer?

A: Yes, samples are free, you are welcomed to get free samples. But you need pay for the courier charges.

Q: What about you delivery time?

A: 7-15 days after we received deposit, according to the quantity and the products level.

Q: Do you have your own factory?

A: Yes, we have our own factory, so we can control the product quality effectively and give prime price to our clients. Welcome you to China for learning more of wear plates.

Q: Can you produce the products as required?

A: Yes, customized products are accepted. You need note us what you need on size, steel name, steel number, MOQ.