Manganese Steel Wear Parts Spares Blow Bar Flat Plate Hammer Suit Np1415 Impact Crusher

Maanshan City Hyton Heavy Industry Technology Development Co., Ltd.- Certification:CE, ISO 9001:2008

- Surface Treatment:Polishing

- Manufacturing Process:Casting

- Material:High Manganese Steel,High Chrome

- Transport Package:Standard Packing

- Specification:standard size

Base Info

- Model NO.:NP1415

- Trademark:Hyton

- Origin:Maanshan China

- HS Code:84749000

- Production Capacity:30000 Ton Per Year

Description

Blow Bar Application Crusher Certificate ISO9001

Products Pictures

Material Composition

High Manganese Steel Blow Bar: Mn18Cr2 C Si Mn P S Cr 1.20-1.35 Max1.0 16-19 Max0.07 Max0.07 1.5-2.5

Chrome Alloy Steel Blow Bar:High chrome,Medium chrome, lower chromeCr C Na Cu Mn Si P 3.5-4.5 2.5-3.5 / / 0.5-1.0 0.5-1.0 ≤0.15 8.0-1.0 2.5-3.6 4.5-6.5 4.5-6.5 0.3-0.8 1.5-2.2 / 13-18 2.8-3.5 0-1.0 0-1.0 0.5-1.0 ≤1.0 ≤0.16 18-23 2.0-3.3 ≤2.5 ≤1.2 ≤2.0 ≤1.2 ≤0.16 23-30 2.3-3.3 ≤2.5 ≤2.0 ≤1.0 ≤1.2 ≤0.16

Main Models We Supply:

NP1213,NP1313,NP1415,NP1620,NP1520,NP1110,NP13,NP15,LT1213,LT1315

CI121,CI123,CI124,CI125,CI221,CI231,CI222,CI232,CI223,CI233,CI224,CI234,CI225,CI235

I-100,I-100RS,I-120,I-120RS,I-140,I-140RS

HS-2421,HS-2430,HS-3036,HS-3048,HS-4230,HS-5252,HS-5263

APP4354,APP5148,APP5560,APP6384,APP8084,APS4034,APS4054,APS5148,APS5160,APS6084

Note: other model we can produce according to customer's drawings.

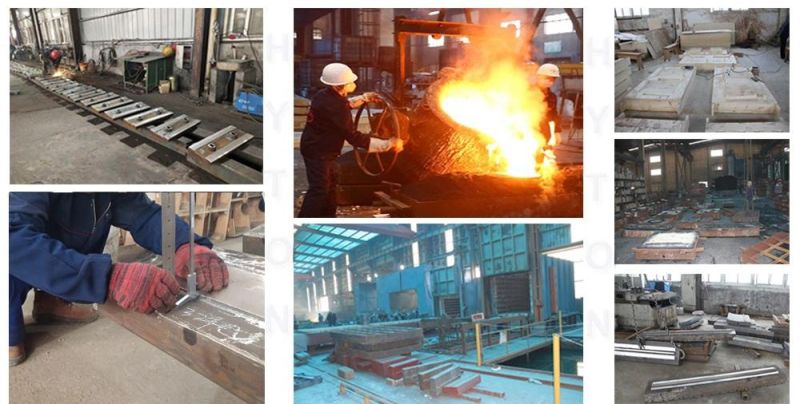

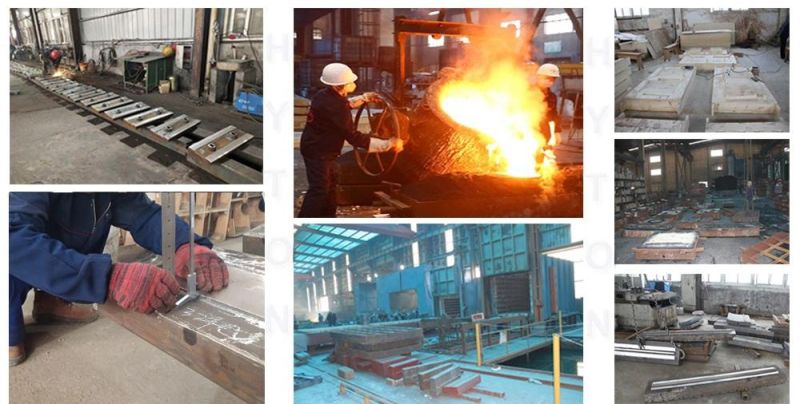

Production Scene

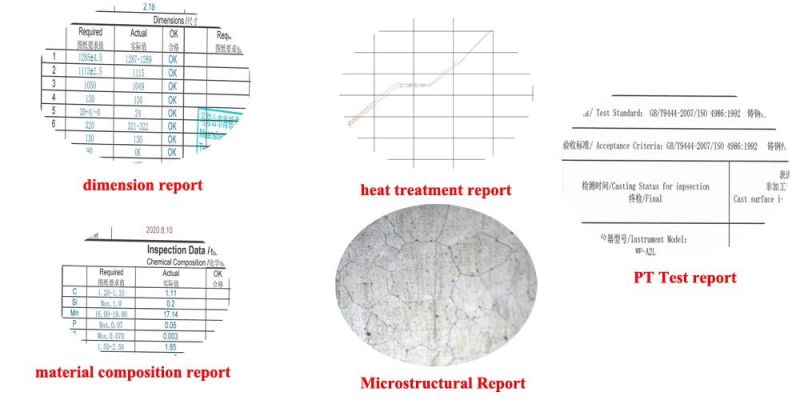

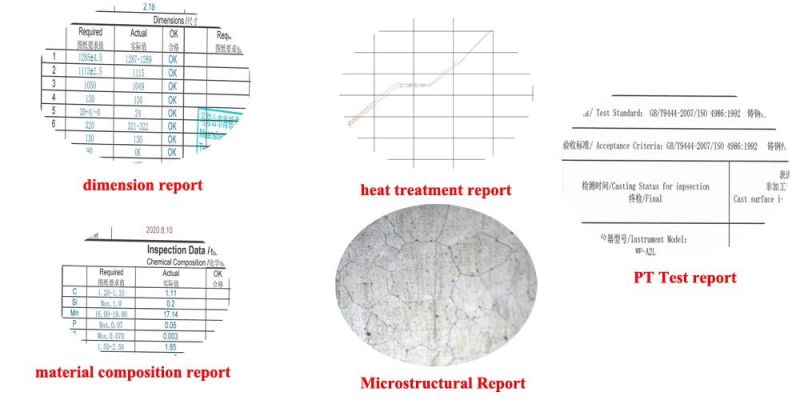

Inspection Reports

We will provide inspection reports for your confirmation before shipment if necessary.

Company Profile

Hyton(Jiangsu) Mechnical Equipment Co.ltd is a leading enterprise in the large-scale engineering machinery wear-resisting casting industry in Jiangsu Province,Nantong City. As a new high-tech enterprise professionally manufacturing wear-resisting casting product Which specialized in manufacturing and research of High manganese and high Chrome wear parts. After ten years of rapid development, Hyton(Jiangsu) has now become a renowned enterprise in China's wear-resisting casting industry; it has become one of the famous supplier of wear parts for crusher and concrete mixer .Established in June 2004, the company is now undertaking a National Torch Program Project, and five of its patented products have been honored as the "New High-Tech Product" of Jiangsu Province two of which have been listed into the New Products Program of Jiangsu Province.The company's wear-resisting casting products have been praised to be the "Famous-brand Products of Jiangsu Province", the company has been appraised as a "Trustworthy" unit of Jiangsu Province for many consecutive years.

Located in the New Material Industrial Park, Nantong City Jiangsu Province. the company covers an area of 90 Square kilometer and currently has more than 300 employees. The company is equipped with lost molding production line and lost casting production line imported from FATA Company in Italy, Inductotherm Vacuum Degassing Furnace(USA), Foseco Casting Technology(U.K), SPECTRO Spectrometer (Germany), the currently most advanced ZZ418A vertical parting flaskless shoot squeeze molding machine Disa production line, horizontal molding line and self-control lost casting production line in China,the most advanced sand treatment system in China,. With three gas trolley heat treatment furnace and pusher-type furnace full-automatic heat treatment production lines, the company can annually produce 30,000 tons of various wear-resisting castings.

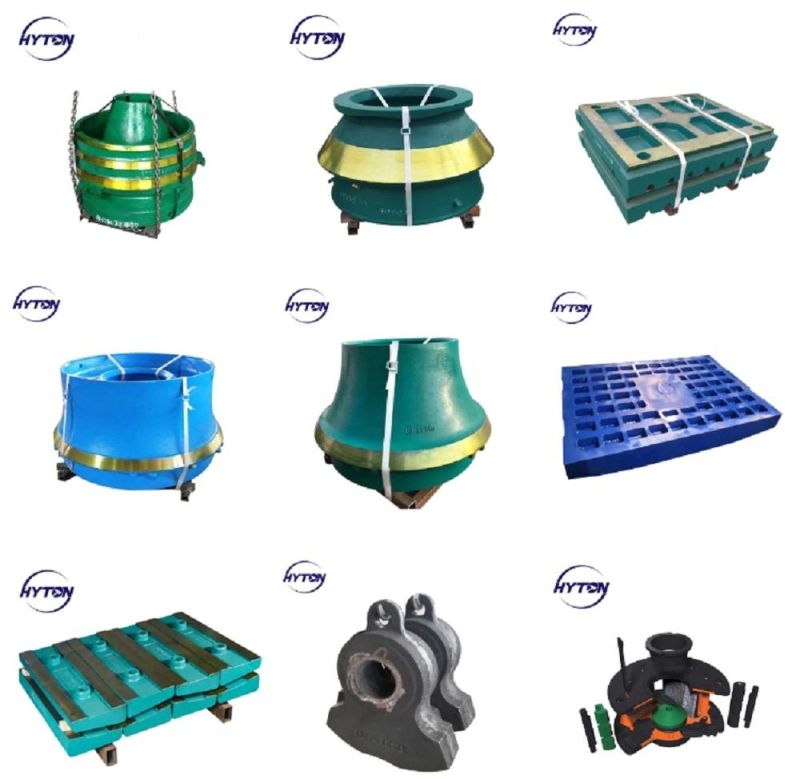

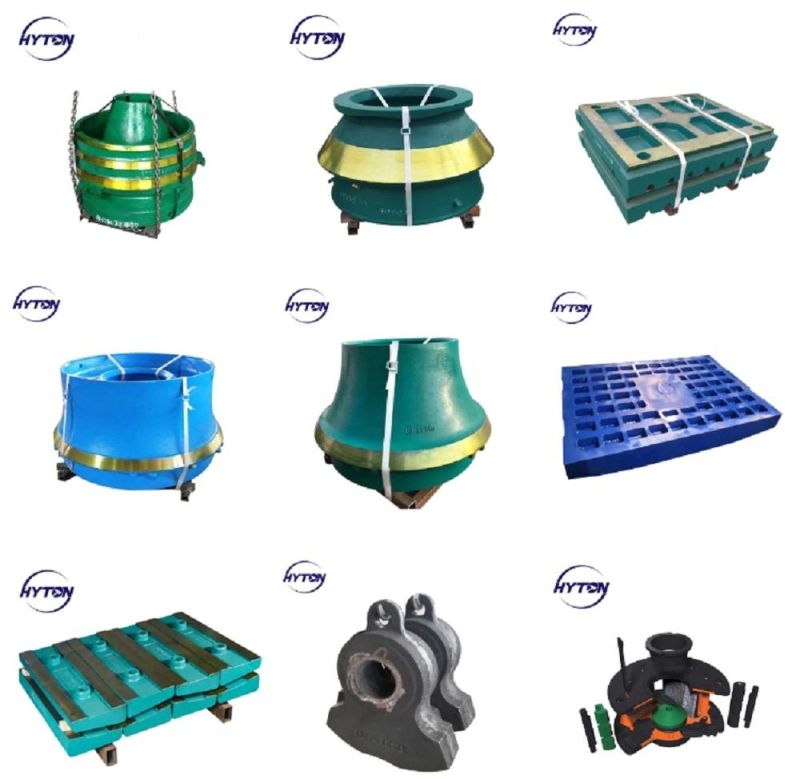

Related Products

Package and Shipment

FAQ

Products Pictures

Material Composition

High Manganese Steel Blow Bar: Mn18Cr2

Chrome Alloy Steel Blow Bar:High chrome,Medium chrome, lower chrome

Main Models We Supply:

NP1213,NP1313,NP1415,NP1620,NP1520,NP1110,NP13,NP15,LT1213,LT1315

CI121,CI123,CI124,CI125,CI221,CI231,CI222,CI232,CI223,CI233,CI224,CI234,CI225,CI235

I-100,I-100RS,I-120,I-120RS,I-140,I-140RS

HS-2421,HS-2430,HS-3036,HS-3048,HS-4230,HS-5252,HS-5263

APP4354,APP5148,APP5560,APP6384,APP8084,APS4034,APS4054,APS5148,APS5160,APS6084

Note: other model we can produce according to customer's drawings.

Production Scene

Inspection Reports

We will provide inspection reports for your confirmation before shipment if necessary.

Company Profile

Hyton(Jiangsu) Mechnical Equipment Co.ltd is a leading enterprise in the large-scale engineering machinery wear-resisting casting industry in Jiangsu Province,Nantong City. As a new high-tech enterprise professionally manufacturing wear-resisting casting product Which specialized in manufacturing and research of High manganese and high Chrome wear parts. After ten years of rapid development, Hyton(Jiangsu) has now become a renowned enterprise in China's wear-resisting casting industry; it has become one of the famous supplier of wear parts for crusher and concrete mixer .Established in June 2004, the company is now undertaking a National Torch Program Project, and five of its patented products have been honored as the "New High-Tech Product" of Jiangsu Province two of which have been listed into the New Products Program of Jiangsu Province.The company's wear-resisting casting products have been praised to be the "Famous-brand Products of Jiangsu Province", the company has been appraised as a "Trustworthy" unit of Jiangsu Province for many consecutive years.

Located in the New Material Industrial Park, Nantong City Jiangsu Province. the company covers an area of 90 Square kilometer and currently has more than 300 employees. The company is equipped with lost molding production line and lost casting production line imported from FATA Company in Italy, Inductotherm Vacuum Degassing Furnace(USA), Foseco Casting Technology(U.K), SPECTRO Spectrometer (Germany), the currently most advanced ZZ418A vertical parting flaskless shoot squeeze molding machine Disa production line, horizontal molding line and self-control lost casting production line in China,the most advanced sand treatment system in China,. With three gas trolley heat treatment furnace and pusher-type furnace full-automatic heat treatment production lines, the company can annually produce 30,000 tons of various wear-resisting castings.

Related Products

Package and Shipment