Bearing Ratainer of Swing Jaw Steel Crusher Part

Qingdao Zhengda Heavy Industry Co., Ltd.- After-sales Service:Shipment Arrangement

- Warranty:1

- Certification:ISO 9001:2000

- Standard:ASTM

- Surface Treatment:Spray-Paint

- Manufacturing Process:Casting

Base Info

- Material:Alloy Steel

- Model NO.:ZD-2-006

- Dia:Max to 1600mm

- Transport Package:Case

- Specification:customizable

- Trademark:ZD

- Origin:Qingdao, China

- HS Code:84749000

- Production Capacity:50000

Description

Basic Info.

Model NO. ZD-2-006 Material Alloy Steel Dia Max to 1600mm Transport Package Case Specification customizable Trademark ZD Origin Qingdao, China HS Code 84749000 Production Capacity 50000Product Description

Basic Info

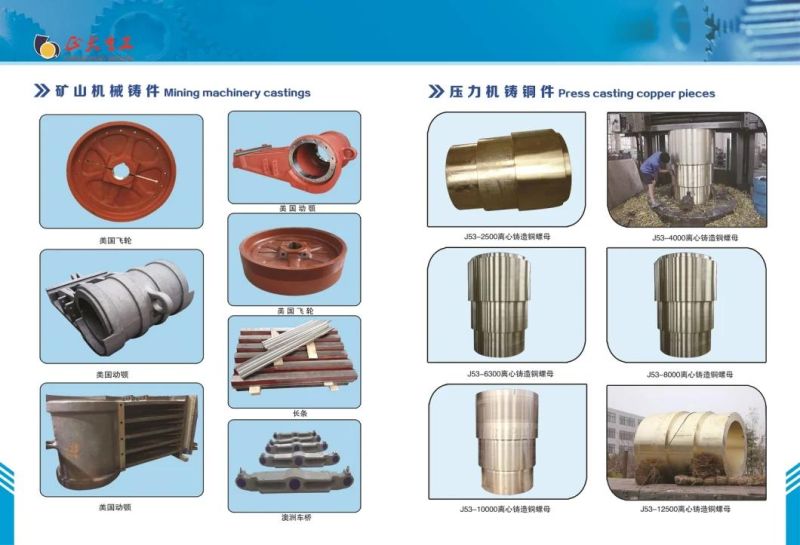

Casting Method: Thermal Gravity Casting

Application: Machinery Parts

Material: Steel

Surface Roughness: Ra12.5

Certification: ISO 9001:2008

Coating: Rust Resistant Coating

Transport Package: Frame or as Your Require

Origin:Qingao, China

Sand Core Type: Resin Sand Core

Machining: CNC Machining

Surface Treatment: Polishing & Machining

Standard: ASTM

Tolerance: +/-0.15mm

Inspection: UT, MT, Laser

Trademark: ZD/ OEM

Specification: DIN, ASTM Standards, et

Weight: 20kg~20T

Applicable device: mill parts

Application: Cement, electricity, Mining, chemical and others

Customizable: Yes

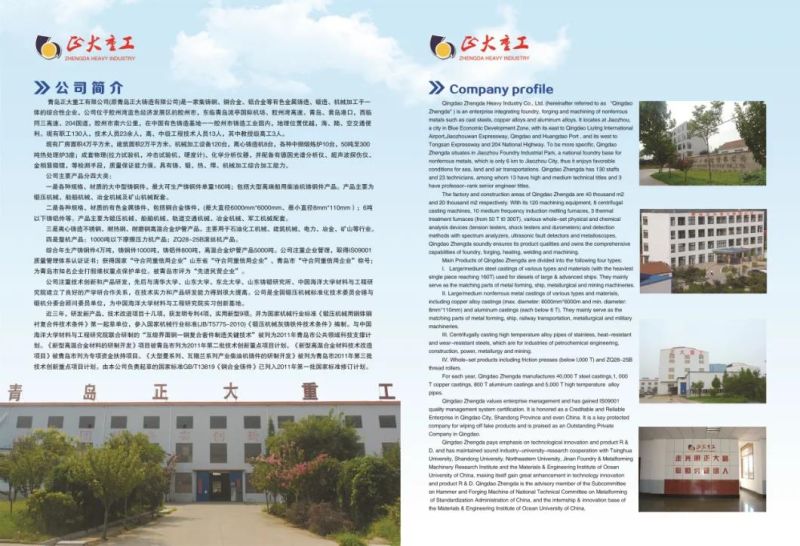

Introduction

Inner oil seal collar is an mechanical component of oil seal, it plays an important role of fixing bearing . It is the core part of rolling bearing.The Oil seal collar works under low speed and heavy load for long time. It will drive parts need to be lubricated with the output parts isolation,so that the oil won't leak. Its reliability is the most important feature. To achieve this feature, it must in good quality .

Advantage

1. Fine material, high level of wear resisting

Qingdao Zhengdao Heavy Industry Co., LTD uses high grade steel to produce the inner oil seal collar, to ensure products' quality. Through the test of practice, it can work well under long-time, heavy load operation with small wear loss.

2. Reasonable structure, good for long-time and stable operation

Removed outside top cover, this design avoids dusts go into bearing box, improves bearing's working life, and secures its work.

Quality Assurance

The fabrication route is governed by the provisions of the implemented Quality System ISO 9001: 2000. The standard documentation ensures the full traceability of every process step:

Manufacturer test certificates according to DIN EN 10.204 § 3.1 including chemical composition, mechanical properties and non-destructive examination;

Dimensional check supported with a "as-built" sketch;

Record of the heat treatment chart;

Oil seal is a mechanical component used to seal oil, it will drive parts need to be lubricated with the output parts iso, so that the oil will not leak.