BBQ Charcoal Bamboo Charcoal Coconut Husk Briquette Machines

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Pressing Mode:Twin-roller

- Product Shape:Oval Shape

- Motor Type:AC Motor

- Condition:New

- Warranty:12 Months

- Type:Briquette Machines

Base Info

- Model NO.:YQJ

- Model Number:Yyq Series

- After-Sales Service Provided:Engineers Available to Service

- Installation:Engineer Guided

- Application:Coal, Charcoal, Oxide Iron

- Quality Guarantee:1 Year

- Packaging Detail:Usually in Bulk, Can Do Special Packing

- Delivery Detail:Within 30 Days or as Required

- Transport Package:Container

- Specification:ISO9001: 2008

- Trademark:HC

- Origin:Henan, China

- HS Code:84748090

- Production Capacity:1-50 Ton,Hour

Description

Basic Info.

Model NO. YQJ Model Number Yyq Series After-Sales Service Provided Engineers Available to Service Installation Engineer Guided Application Coal, Charcoal, Oxide Iron Quality Guarantee 1 Year Packaging Detail Usually in Bulk, Can Do Special Packing Delivery Detail Within 30 Days or as Required Transport Package Container Specification ISO9001: 2008 Trademark HC Origin Henan, China HS Code 84748090 Production Capacity 1-50 Ton/HourProduct Description

BBQ Charcoal Bamboo Charcoal Coconut Husk Briquette Machines

About the briquette machine manufacturer:

Briquette machine Introduction:

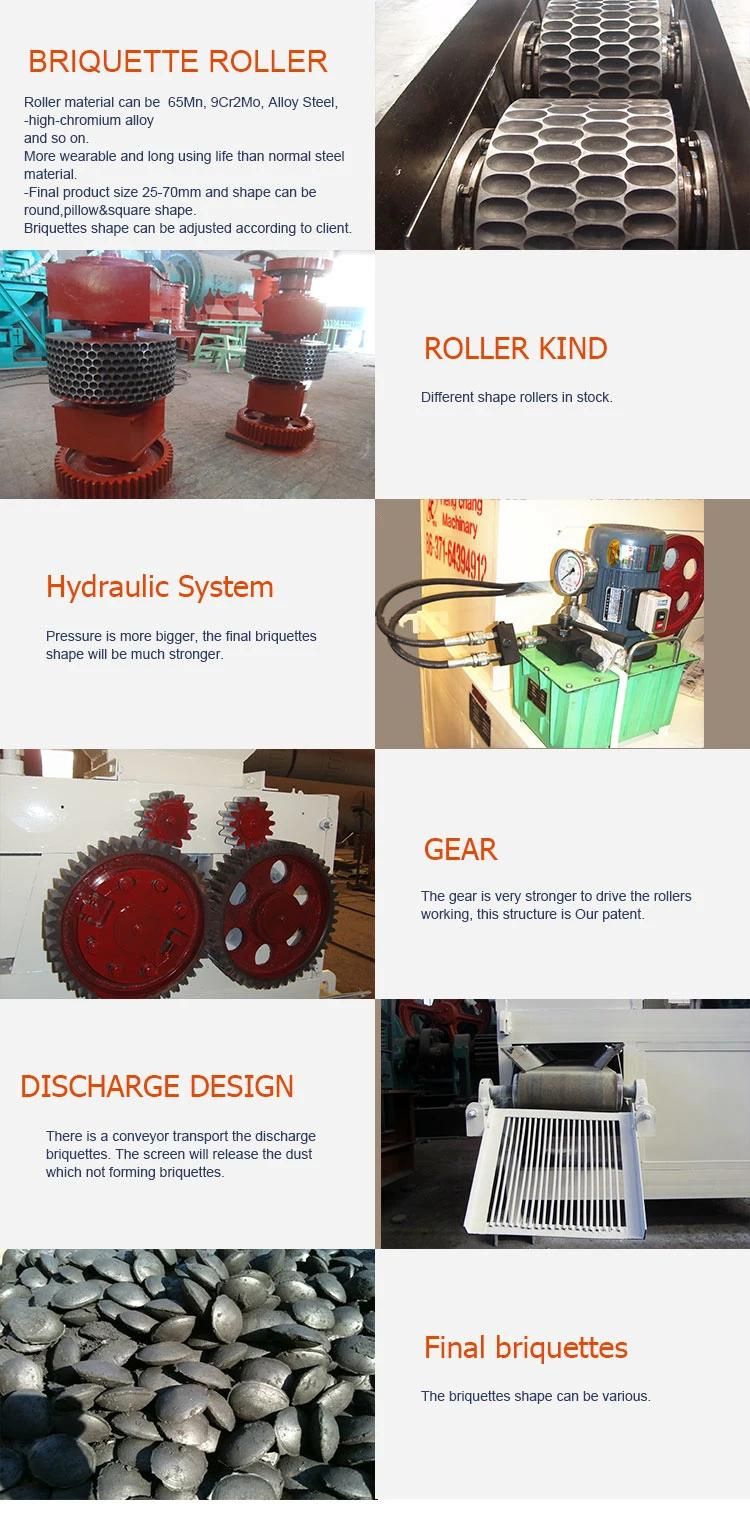

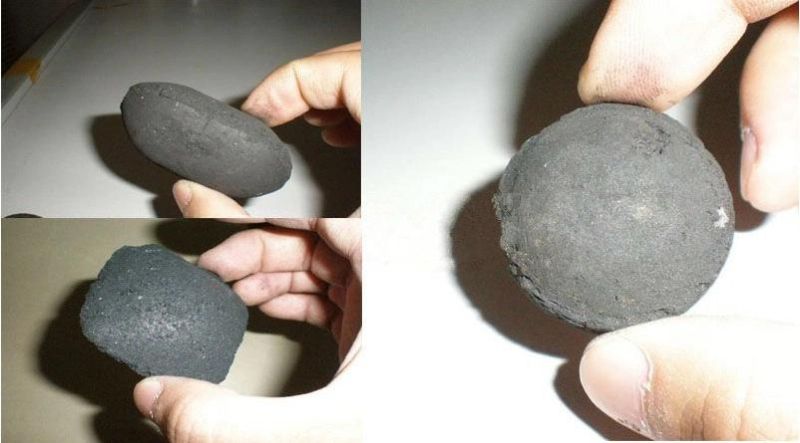

briquette machine briquette making machine is widely used in the briquette making industry, the material it press including the coal, charcoal, metal powder.With the high pressure of 100ton. It surely can press the material into the hard ball.

We are the professional Briquette machine manufacturer in China. we have more that twenty years of experience in making briquette machine. we can provide you the related informations about the briquette machine. Including the following aspects.

1. If you do not know the whole briquette plant operating. It does not matter, we will tell you the whole briquette plant operating principle.

2. Do not worried the machine operating, you can us the sample of the coal, and we can have a free test on the briquette machine.

3. After long time of using, how can i do with the coal briquette machine wearing parts, We can provide you the wearing parts with the factory price.

4. How about the installation of the briquette machine? Do not worried about it, we can provide you the free training about the whole briquette machine operating.

Briquette machine whole plant:

briquette machine briquettes making process can be devided into the following steps: Feeding-- crushing---- mixing------ ball pressing------ drying------final product.

Feeding and crushing: Feed the material into the compound crusher, to crush the material into the very small powder.

Mixing and briquetting: To fully mixing the powder in the dual shaft mixer and add the binder into the powder. Then the fully mixed powder will be feed into the briquette machine.To press the powder into ball shape that you required.

Drying: After the briquettes come out. It contains the humidity. you have to dry the ball become it come to the practical use. we can provide you the horizontal dryer or the vertical dryer to dry the briquettes Briquette machine technical parameter:

Briquette machine technical parameter:

| Model | Roller Dia. (mm) | Roller Width(mm) | Motor Power (kw) | Shaft Speed(r/min) | Reducer Model | Capacity (t/h) | Pressure Form | Roller Material |

| YYQ-476 | 476 | 210 | 22/1.5 | 15 | ZQ500 | 3-6 | Hydraulic Pressure | 65Mn |

| YYQ -476 | 476 | 260 | 30/1.5 | 15 | ZQ650 | 4-8 | Hydraulic Pressure | 9Cr2M0 |

| YYQ -500 | 500 | 300 | 30/1.5 | 15 | ZQ650 | 5-9 | Hydraulic Pressure | 65Mn/9Cr2M0 |

| YYQ -650 | 650 | 336 | 45/1.5 | 15 | ZQ750 | 8-15 | Hydraulic Pressure | 65Mn |

| YYQ -672 | 672 | 275 | 75/1.5 | 13 | ZQ1000 | 8-15 | Hydraulic Pressure | 9Cr2Mo |

| YYQ -750 | 750 | 400 | 55/1.5 | 13 | ZQ850 | 15-20 | Hydraulic Pressure | 65Mn/9Cr2Mo |

| YYQ -850 | 850 | 500 | 75/1.5 | 10 | ZQ850 | 20-30 | Hydraulic Pressure | 65Mn/9Cr2M0 |

| YYQ-1000 | 1000 | 650 | 110/1.5 | 10 | ZQ1000 | 30-50 | Hydraulic Pressure | 65Mn/9Cr2M0 |

Factory:

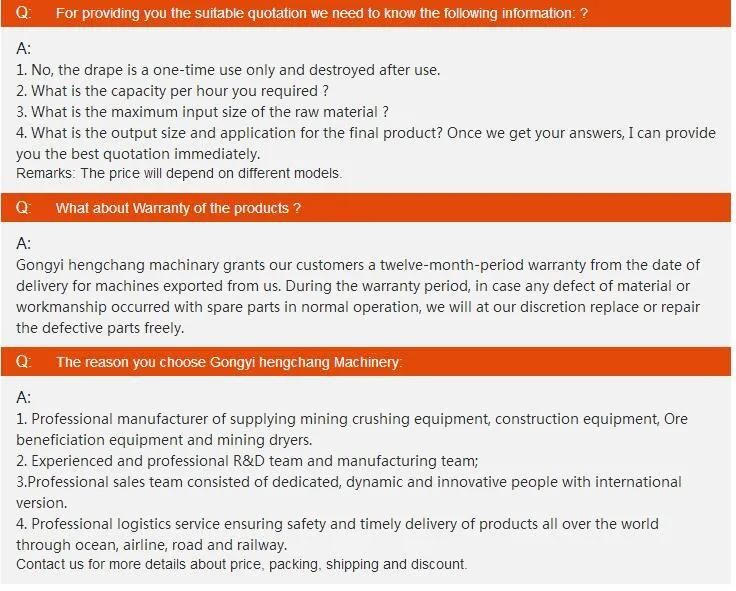

FAQ: