Energy-Saving Mine Roller Press for Grinding of Clinker

Luoyang Zhongtai Industries Co., Ltd.- Type:Cement Roller Press

- Motor Type:AC Motor

- Motor Power:Cement Roller Press

- Rotationl Speed:Hpgr

- Application:Cement Roller Press

- Materials:Cement Roller Press

Base Info

- Model NO.:mine roller press

- Condition:New

- Warranty:One Year

- After-sales Service:on Line 24 Hours

- Roller Press:Cement Roller Press

- Feed Size mm:25,40

- Output Size mm:<2mm 65% <0.08mm 25%

- Capacity:50-1450 Tph

- Transport Package:Standard

- Specification:GM1700-1400

- Trademark:ZTIC

- Origin:Luoyang, Henan

- HS Code:8474202000

- Production Capacity:200PCS,Year

Description

1. The press roller surface adopts hard alloy stud setting-in structure to increase the life time of the roller sleeve

2. Universal coupling-planetary retarder-press roller to consist of shaft flexible drive system

3. Compound structure of non-contact sealing and contact sealing are adopted at the side of the press roller

4. Unique ellipse structure is used for the feeding pipe to make the feeding process smooth

5. Oil spray lubrication system is used for the lubrication of the main bearing

6. The main bearing adopts inner passage fully-sealing structure for cooling

7. The hard alloy welding press roller surface or setting-in surface are available depending on the user's need.

Applicable scope

1. Applicable for the mineral processing industry; it can be installed before the ball mill as pre-milling equipment or consist of mixing grinding system with ball mill.

2. Applicable for oxide pellet industry instead of the common used damp mill.

3. Applicable for building material and fire-proof material industry; successful application for the grinding of clinker, limestone and bauxite.

The principle structure of high-pressure roller mill

High-pressure roller mill is a type of new mineral rock grinding equipment with high efficiency and energy-saving developed based on the lamination crushing principle. The materials enter into the crushing cavity between 2 rollers passing the feeding device with the help of the gravity when working. The material is brought into the cavity continuously. The material is forced to accept the direct pressure from the surface. The 2 rotary rollers will press the material in the crushing cavity solid so that the particles in the group will bear pressure at multiple points. Thus, the material volume weight in the pressing area is 85% of the actual density. The particles are crushed in the group be mutual pressing. Different particle crushing is caused due to different pressures. So the particle size is widely distributed and the piece of material cake is discharged. The material cake contains some sub-particles. There are many cracks in the particles to reduce the particle strength, which is good for the following grinding to reduce the power consumption of the whole milling system significantly.

Type description:

Type

Press roller diameter

(mm)

Press roller width

(mm)

Power(kw)

Feeding particle size (mm)

Product particle size

(mm)

Passing capacity

(t/h)

Weight(t)

90%

10%

70%-80%

GM52-20

520

200

2×90

≤25

26-40

≤3

31

13

GM65-22

650

220

2×110

≤25

26-40

≤3

43

19

GM80-30

800

300

2×132

≤25

26-40

≤3

70

30

GM90-30

900

300

2×150

≤25

26-40

≤3

129

38

GM100-40

1000

400

2×200

≤25

26-40

≤3

192

55

GM100-50

1000

500

2×280

≤25

26-40

≤3

240

60

GM120-60

1200

600

2×355

≤30

26-40

≤3

312

86

GM120-70

1200

700

2×400

≤30

26-40

≤3

403

93

GM120-80

1200

800

2×500

≤30

26-40

≤3

460

98

GM140-80

1400

800

2×550

≤30

26-40

≤3

538

110

GM140-110

1400

1100

2×800

≤30

26-40

≤3

739

133

GM140-140

1400

1400

2×1000

≤30

26-40

≤3

941

156

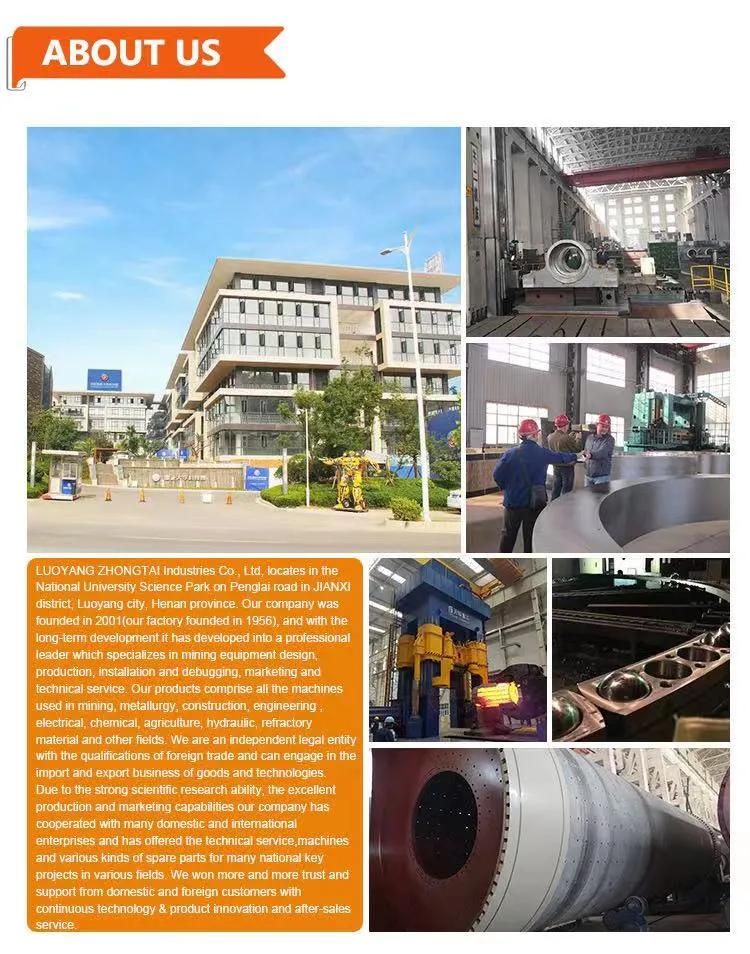

Company Information

FAQ

FAQAfter Sales Service

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS