Professional Tube Grinding Mill Used in Industrial Construction

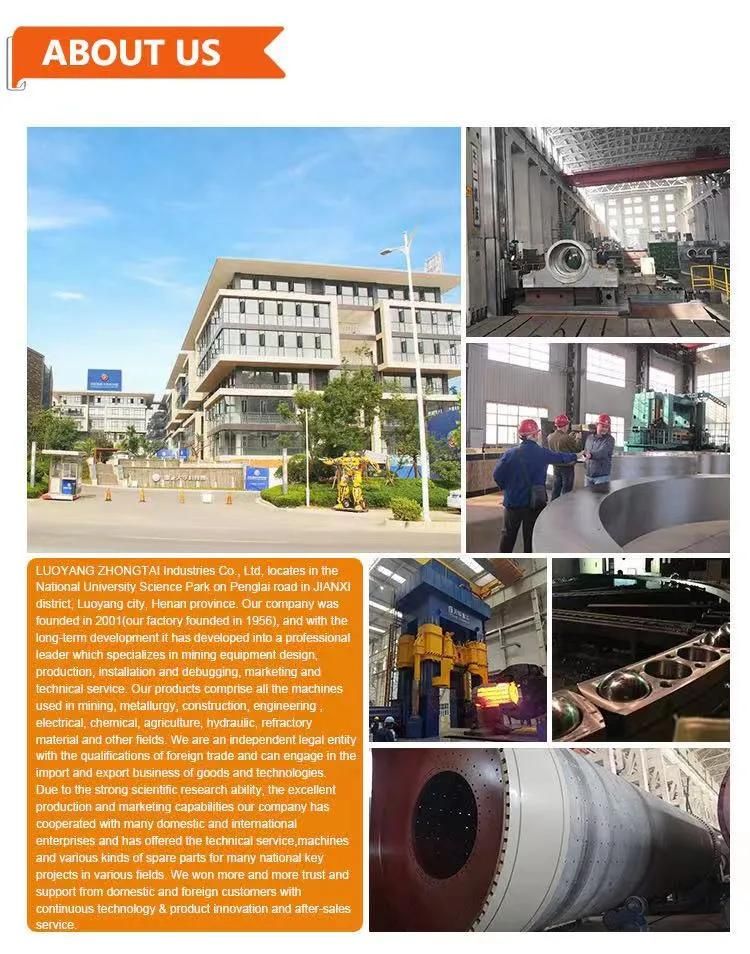

Luoyang Zhongtai Industries Co., Ltd.- Type:Tube Grinding Mill

- Motor Type:AC Motor

- Motor Power:380-4200 Kw

- Rotationl Speed:Tube Grinding Mill

- Application:Construction

- Materials:Tube Grinding Mill

Base Info

- Model NO.:tube grinding mill

- Condition:New

- Warranty:a Year

- After-sales Service:Twenty Four Hour Online

- Application Industry:Tube Grinding Mill

- Output:14-195 Tph

- Weight:49-485 T

- Dimension(L*W*H):2.2X6.5-4.6X14 M

- Transport Package:Simpke Packaging

- Trademark:LYZT

- Origin:Luoyang, Henan

- Production Capacity:500PCS,Year

Description

Tube Grinding Mill:

We have first-rate Tube Grinding Mill research and design team, perfect test and inspection means .

Product Description

Compact and efficient!

ZTIC Tube Mills are space-saving, compact, high on performance and low on maintenance. This is primarily due to the support bearing design and the mill drive used. The mill is shell-supported, mounted on slide shoe bearings at both ends and made completely as a welded design. The mill with the compact drive version features an INTEGRAL DRIVE, whose planetary gear is mounted to the mill flange. ZTIC Tube mills are the result of the most advanced calculation and simulation methods, backed by years of experience. Worldwide we have designed and built more than 1,000 tube mills.

Our driving force

The standard CITIC mill is shell-supported on slide shoes and has a central drive. Torque transmission is effected via the conical discharge end. This cone is welded to the mill shell and has openings for the discharge of material and exhaust gases. The drive flange is connected to the end of the cone. In this way, the drive force is distributed directly and evenly to the mill shell.

All standard types of mill drives can be connected, such as:

Central Drive

INTEGRAL DRIVE

Girth Gear and Pinion Drive

High on performance, low on space requirements: INTEGRAL DRIVE

Our mills for minimum space requirements are mounted on slide shoe bearings and have an INTEGRAL DRIVE. The core of this drive is a two stage planetary gear reducer, which is directly mounted on the end cone. Only one short slide seal at the motor end and a closed oil lubrication system extend the time between oil changes and reduce the risk of entering of dust particles. Installation is fast and easy. No time consuming adjustments. Our INTEGRAL DRIVE is the most economic drive due to its high availability and a mechanical efficiency level of almost 99%.

Specification (diameter×length)

(r/min)

22~28

21~23

24~26

(main bearing type)

(main bearing type)

(main bearing type)

Note: Parameters in the form are only for reference, so for specific ones, customers need to refer to the contract.

Technical Parameters of Raw Mill:

Specification (diameter×length )

(r/min)

(Cantilever drying)

(Cantilever drying)

Note: Parameters in the form are only for reference, so for specific ones, customers need to refer to the contract.

Technical Parameters of Wet Raw Mill:

Specification (diameter×length )

(r/min)

(t)

Note: Parameters in the form are only for reference, so for specific ones, customers need to refer to the contract.

Technical Parameters of Drying Raw Mill:

Specification (diameter×length )

(r/min)

(t)

38~40

46~48

45~48

Note: Parameters in the form are only for reference, so for specific ones, customers need to refer to the contract.

FAQ

FAQ

After Sales Service

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

Our mode of transport is taken according to each country's situation is different transportation, while our packaging, according to the latest customs situation, constantly updated, improved our packaging, we guarantee that you receive it within 3-7 working days to your product.

High quality service :

Best Service with after-sales service and consultation,we have an excellent customer service driven approach to our

business, unlike most sites we are consistently available via sales hotline, email, skype or MSN and always respond to

emails within 30 mins

Pre-Sales Service

• Provide details about the production procedure

• Assign engineers for installation and testing

Sales Service

• Customized solution designs

• Product rendering and steel structure drawing

•successful project examples and visits to our production and R&D base

After-Sales Service

• Two-year quality warranty with lifelong maintenance.

•Free guarantee repair (including labor and material): free repair service during the quality warranty period and reasonable charge for spare parts and maintaining service after the quality warranty period. We will never exempt our responsibilities on product owned defects.

•Responding time: upon receiving user's notification, we ensure 24-hour after-sales technical support.