Falcon Centrifugal Concentrator for Gold Processing Plant

Jiangxi Hengchang Mining Machinery Manufacturing Co., Ltd.- Type:Gravity Separator

- Voltage:220V,380V,440V

- Weight:1100kg

- Material:Manganese Steel and Stainless Steel

- Material Feature:Wear-Resistant, Anti-Corrosion

- Certification:ISO9001:2008, ISO9001:2000, CE, SGS

Base Info

- Model NO.:STLB 60 Falcon Centrifugal Concentrator

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Can Be Customized According to Customer Requiremen

- Customized:Can Be Customized According to Customer Requiremen

- Condition:New

- Feeding Density:0-50%

- Feeding Size:0-5mm

- Capacity:8-12tph

- Dimension:1820*1450*1700mm

- Power:4kw

- Transport Package:by FCL or LCL

- Specification:Standard

- Trademark:Hengchang Falcon Centrifugal Concentrator

- Origin:Jiangxi Province China

- HS Code:8474100000

- Production Capacity:1000 Sets Per Year

Description

Basic Info.

Model NO. STLB 60 Falcon Centrifugal Concentrator Energy Saving Energy Saving Warranty 1 Year Color Can Be Customized According to Customer Requiremen Customized Can Be Customized According to Customer Requiremen Condition New Feeding Density 0-50% Feeding Size 0-5mm Capacity 8-12tph Dimension 1820*1450*1700mm Power 4kw Transport Package by FCL or LCL Specification Standard Trademark Hengchang Falcon Centrifugal Concentrator Origin Jiangxi Province China HS Code 8474100000 Production Capacity 1000 Sets Per YearProduct Description

Falcon Centrifugal Concentrator For Gold Processing Plant

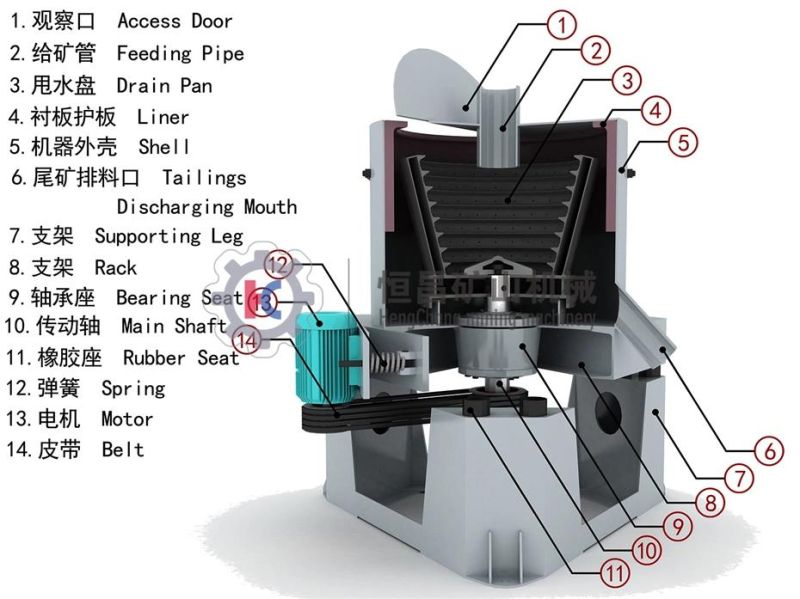

Falcon Centrifugal Concentrator For Gold Processing Plant Hengchang Falcon Centrifugal Concentrator is a kind of gold gravity equipment. It can be used not only for placer gold mining, but also for hard rock mining to recover the natural gold, replacing amalgamation. It is also used to recover gold from the old tailings.

Five models are available. Application shows that the recovery can be as high as 90%, especially for the case in recovering the natural gold in lode ore with 65% of the ore having a milling size of 0. 074mm, the recovery for the natural gold is expected up to 98%, For that natural gold of 0.004mm in particle size, the recovery is 97%. The cleaning up cycle is 1~4 hours, and the upgrade ratio is up to 1,000 times. The equipment is patented in China.

Five models are available. Application shows that the recovery can be as high as 90%, especially for the case in recovering the natural gold in lode ore with 65% of the ore having a milling size of 0. 074mm, the recovery for the natural gold is expected up to 98%, For that natural gold of 0.004mm in particle size, the recovery is 97%. The cleaning up cycle is 1~4 hours, and the upgrade ratio is up to 1,000 times. The equipment is patented in China.Operation of Centrifugal Concentrator

Before starting the preparation and check:1. According to the instructions of motor required for the preparation and check before use.

2. Check the equipment whether the anchor is stable.

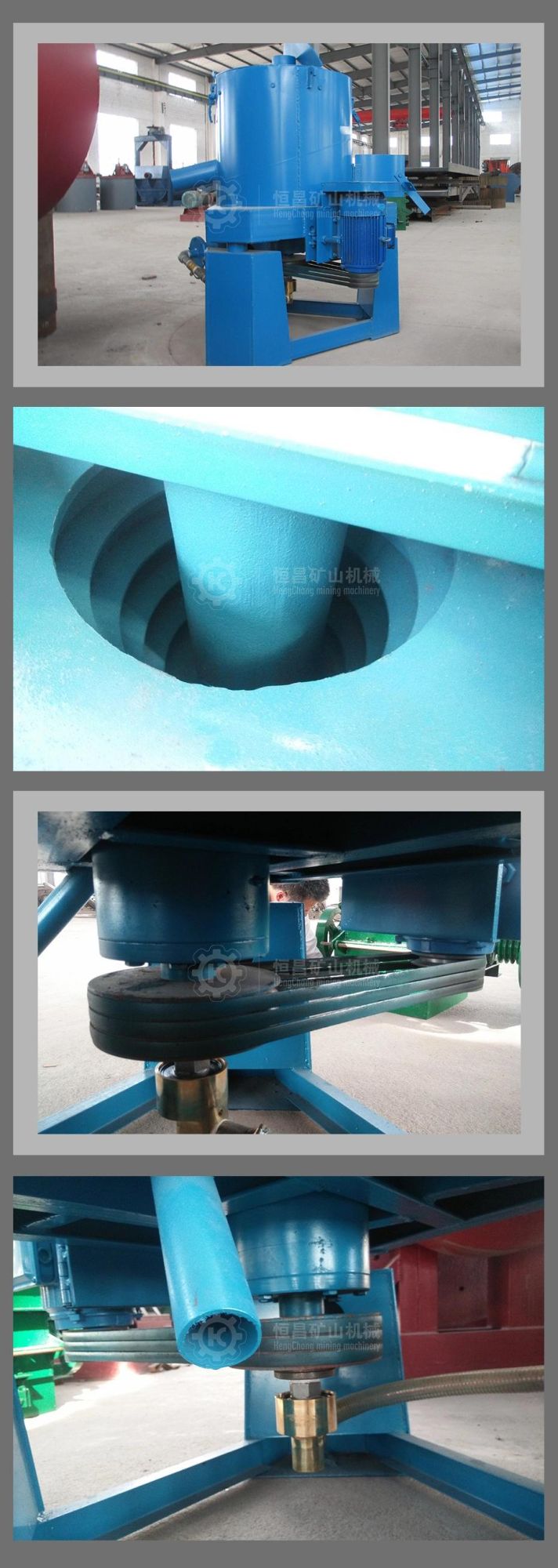

3. Check the state of V-belt tension and adjust appropriately (factory test machine has made adjustments)

4. Check the equipment without interference of moving parts, manual turning checks.

5. Check the discharge port (10) is closed.

Start-Up of Falcon Centrifugal Concentrator

After the above five ready to check , turn the power to start the motor, check motor rotation direction and equipment requirements are the same, whether the interference of moving parts, and then turn on the power, make the equipment into normal operation.Equipment work note for Falcon Centrifugal Concentrator

1 monitor the stability and current by use of conventional motor.2 watch every moving parts without exception condition,.

3 pay attention to slurry ratio, try to adjust it in time.

4 intervals for a period of time, open the peephole on the cover, observation of inner sleeve

Stop of Falcon Centrifugal Concentrator

The equipment need clean up concentrates per normal work shift. Before stop, first stop feed mine, then stop the equipment, wait for equipment is stationary, unscrew the drain plug concentrate outlet , the ore concentrate into the ore tank (prepared in advance) can be. Cleaning concentrate time to 15 to 20 minutes. Then, tighten drain plug, the next cycle of operation.If meet special condition, need to temporary shutdown, must first stop to feed mine, then stop backwash water, and then go down.But the downtime should not be too long, too long to prevent resolve within the set of grid sand compaction. (if required downtime long, you need to clean the concentrate first, hen shutdown.) In addition, when you open again after temporary shutdown, need feed slurry first, and then give backwash water, to void the loss of gold particles.

Main Technical Parametera of Flcon Centrifugal Concnetrator

Model | STL-20 | STL-30 | STL-60 | STL-80 | STL-100 |

Capacity (t/h) | 0.2-0.6 | 2-3 | 10-20 | 35-45 | 60-120 |

Feeding size (mm) | 0-3 | 0-4 | 0-6 | 0-6 | 0-6 |

Feeding density (%) | 0-50% | 0-50% | 0-50% | 0-50% | 0-50% |

Backwash water (t/h) | 1.5-2 | 4-6 | 10-15 | 17-25 | 40-60 |

Output(kg/time) | 2-3 | 10-20 | 30-40 | 60-70 | 70-80 |

Motor power (kw) | 0.75 | 1.5 | 5.5 | 11 | 18.5 |

Revolution ® | 800 | 600 | 460 | 400 | 360 |

Pressure water (Mpa) | 0.04 | 0.12 | 0.25 | 0.35 | 0.4 |

Dimension (mm) | 790x785x790 | 1180x1140x1250 | 1970x1670x1750 | 2300x1800x2200 | 2500x2000x2400 |

Weight (kg) | 145 | 400 | 1300 | 2000 | 2500 |