Vertical Mill Raymond Mill Used in Industrial Construction

Luoyang Zhongtai Industries Co., Ltd.- Type:Vertical Mill

- Motor Type:AC Motor

- Motor Power:110-6600kw

- Rotationl Speed:Cement Vertical Mill

- Application:Construction

- Materials:Cement Vertical Mill

Base Info

- Model NO.:Raymond vertical mill

- Condition:New

- Warranty:a Year

- After-sales Service:Twenty Four Hour Online

- Raymond Mill:Stone Raymond Mill,Limestone Raymond Mill

- Model:3r-6r

- Particle of Finished Product(mm):0.125- 0.044

- Material Fine Degree(T):0.5-120

- Rotate Speed of Central Shaft (R/Min):82-280

- Inner Diameter of Pulverzing Ring (mm):495-1770

- Transport Package:Simple Packaging

- Trademark:ZTIC

- Origin:Luoyang, Henan

- Production Capacity:500PCS,Year

Description

raymond mill

Raymond mill is used for grinding more than 280 kinds of materials whose Mohs hardness is less than 9.3 such as the barite, limestone, kaolin and slags, etc.

Features:

Small covering area, strong completenes

The granularity of the finished products is even

Smooth transmission and reliable operation

The abradability of the whole machine is high

Features

The Raymond mill is used for grinding more than 280 kinds of materials whose Mohs hardness is less than 9.3 such as barite, limestone, kaolin and slags, etc in the mining, metallurgical industry, chemical engineering and building material for high fine powder generation and processing. The product size is adjustable in the range of 80-325 mesh.

Structural Advantages of Raymond Mill

1. Driving system of main frame adopts airtight gearing and pulley to guarantee the smooth drive and reliable operation.

2. The whole plant is a vertical structure of strong systematic characteristic, so it occupies small area. The crushing of raw material, grinding and packing is an independent production system.

3. The electric control system is controlled centralizedly, so the automaticity is high, the people is not needed in the operating room.

4. Main parts of the whole plant are made of cast and steel of high quality. The subtle technics ensures the durability of whole plant.

5. Compared with other milling plants, its passing ratio achieves 99%, which is what other mill can not reach.

Model

0.044

0.044

0.044

0.044

0.044

0.044

0.044

0.044

4-132

4-75

4-37

8-30

8-22

8-18.5

8-15

6-7.5

4-132

4-75

4-37

4-22

4-15

4-15

4-11

2-5.5

4-11

4B-7.5

4a-5.5

6-2.2

6-2.2

6-202

6-2.2

6-1.1

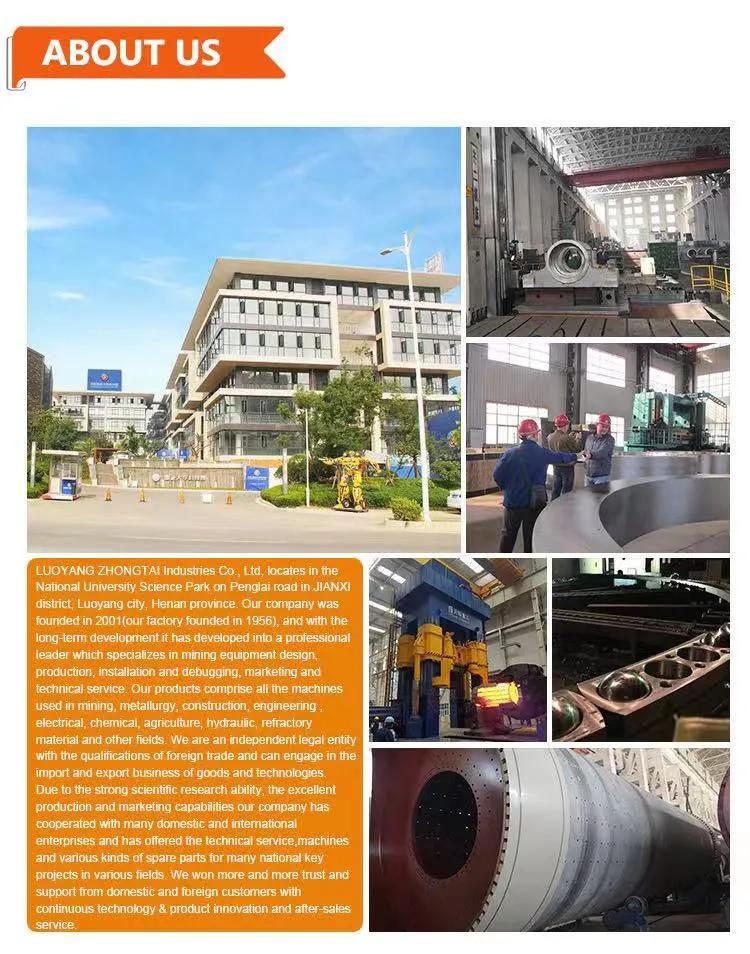

Company Information

FAQ

FAQ

After Sales Service

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

ZTIC's Field Service Engineers are trained specifically in the CITIC brand group products but are capable of undertaking the servicing of other OEM brands.

Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time.

ZTIC also has an extensive capability in supplying all you consumable and electrical/ mechanical spare part needs.