Professional Superfine Mesh Mica Powder Shredder

Zhejiang LEAP Pulverization Equipment Co., Ltd.- Type:Roller Mill

- Motor Type:AC Motor

- Motor Power:30KW

- Rotationl Speed:295r,Min

- Application:Mine

- Materials:Mica

Base Info

- Model NO.:ACJ-650

- Condition:New

- Main Material:Carbon Steel or 304 Stainless Steel

- Bearing:FAG

- Spare Parts:Available

- OEM&ODM:Available

- Certificate:ISO9001,Ce,TUV,SGS

- Transport Package:Wooden Pallet

- Specification:ISO9001

- Trademark:OEM

- Origin:China

- HS Code:8479820090

- Production Capacity:50 Set,Month

Description

parameter

(wood chips 150~600)

FAQ

1.What material you want to grind,is it dry, what is the size of feed material?

2.What capacity you expect? (kg/h)

3.What mesh or mm or micron(size) of the powder you want ?

4.What voltage you want ? For example,380V 50Hz, 3P ..

We know that a good and satisfying powder grinding mill manufacturer and supplier should not only provide high quality products,but also complete customer services.

We provide the following services:

Technical support

Upon receiving the deposit,we will offer the following technical services:

1.Design for your production line flow and equipment layout,free of charge;

2.Provide foundation drawings of customer-ordered grinding mills and drawing of related parts,etc;

3.Technical parameters of peripheral equipment will be supplied

4.Free technical suggestions on adjusting of equipment layout and application

5.Equipment upgrading(customers need to pay the cost);

Quality assurance

1.Strictly conforming to ISO9001-2000 quality management system.

2.Strict control from purchasing inspection,process inspection to final proofing;

3.Establish several QC departments to execute quality control regulations;

4.Detailed quality control examples;

1)Complete files for quality control and quality feedback.

2)Strict inspection for the components of our grinding mills,to assure products free of damage and avoid rust-eaten and paint peeling off later on.

3)Only qualified components will be assembled and total equipment must be inspected completely before sales.After sales service

1.We will send our technician to the site for guiding equipment installation and commissioning

2.During the installation and commissioning,we offer operator training service

3.The quality assurance date is one year after commissioning,and after that, we will collect the cost if provide repairing for your equipment.

4.Maintenance for equipment failure caused by improper handling(appropriate cost will be collected).

5.We offer the components with favorable price and perdurable maintenance.

6.If equipment repairing is needed after quality assurance date is expired,we will collect maintenance cost.

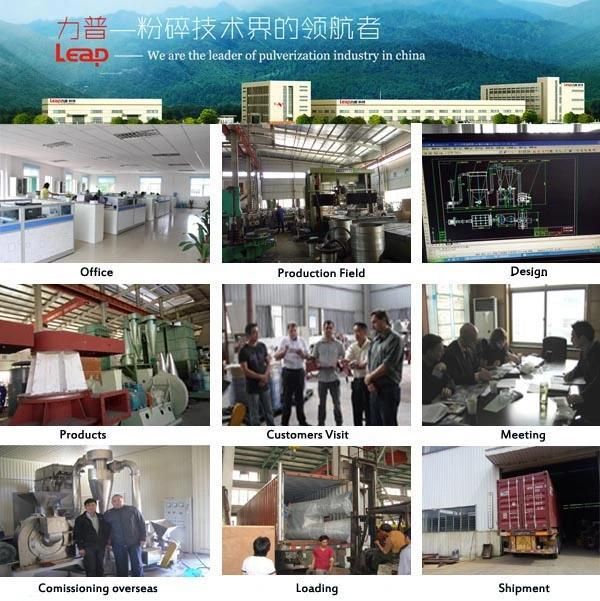

Welcome to visit our factory !