ISO Quality Gold Ore Small Ball Mill Ball Mill Grinder

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:15KW

- Rotationl Speed:20-22r,min

- Application:Mine

- Materials:Gold

Base Info

- Model NO.:YMQ900*2100

- Condition:New

- Machine Motor Type:AC Motor

- Machine Type:Ball Mill

- Machine Rotationl Speed:21-23r,Min

- Application Materials:Gold, Silver, Lead, Zinc

- Machine Motor Power:15kw

- Machine Condition:New

- Quality Certificate:ISO: 9001: 2001

- Spare Parts:Supply in Whole Life

- Power:15kw

- Capacity(T/H):1-50 Ton,Hour

- Transport Package:Standard Shipment Package

- Specification:ISO9001

- Trademark:HC

- Origin:China Henan

- HS Code:8474209000

- Production Capacity:20 Sets,Month

Description

Advantages of ISO Quality Energy Saving Gold Ore Small Ball Mill1 20 years' original manufacturer 2 High efficiency, Stable performance 3 ISO 9000; 2008 certified 4 Easy to operate, low maintaince

Description

Ball Mill save energy and high capacity is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grind-able materials

Features

1) Gold ore processing machine is an efficient tool for grinding many materials into fine powder;

2) The gold ore processing machine is used to grind many kinds of mine and other materials, or to select the mine;

3) Gold ore processing machine is widely used in building material, and chemical industry.

4) There are two ways of grinding: the dry way and the wet way.

5) Gold ore processing machine can be divided into tabular type and flowing type according to different expelling mine

6) To use the gold ore processing machine, the material to be ground is loaded into the neoprene barrel that contains grinding media.

7) As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

8) The longer the ball mill runs, the finer the powder will be.

9) Ultimate particle size depends entirely on how hard the material you're grinding is, and the time how long the ball mill runs.

10) Our ball mills have been used to grind glass, powder food products, create custom varnishes, make ceramic glaze, powder various chemicals

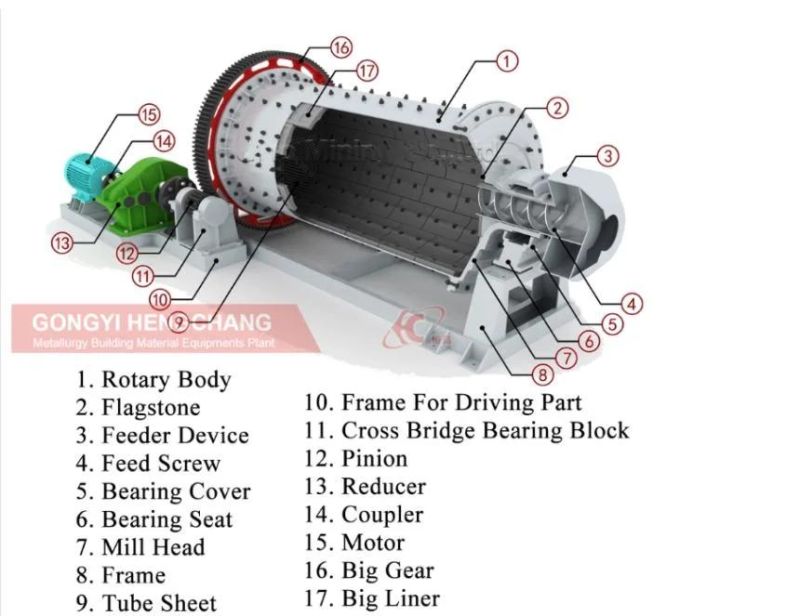

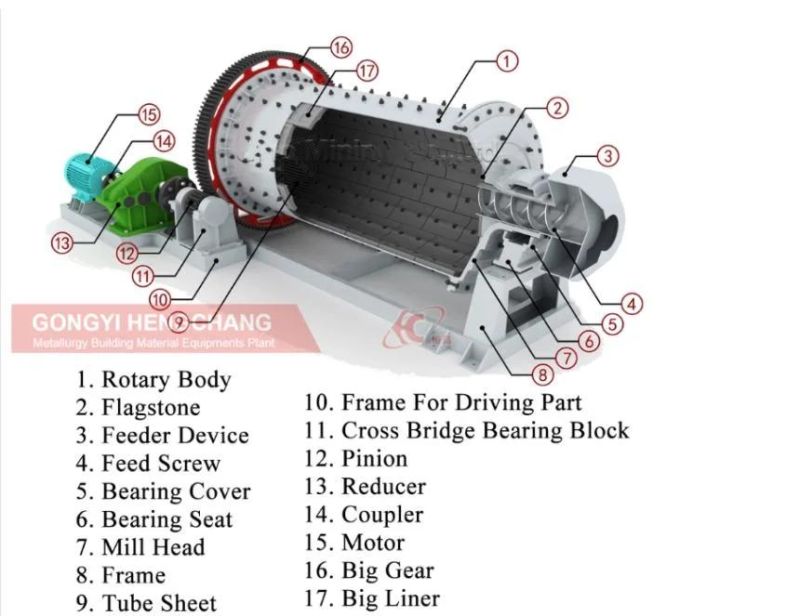

Working Principle of ball mill:

The ball mill is horizontal cylindrical rotation device, driven by brim gearwheel. There are two chambers and grid of ball mill. Material goes into the first chamber through the feeding inlet. Inside the first chamber, there are stage liners and ripple liners as well as steel balls. The ball mill shell rotates so as to generate electricity, and this force brings ball to a certain height and then balls drop down by gravity, the impact is the grinding force to the material. After the primary grinding, materials go into the second chamber through segregate screen. In ball mill second chamber, there are flat liners and steel ball. After the secondary grinding, material is discharged from the discharging mouth. Then the whole grinding process is ended.

Technical data

Model

Rotate Speed (r/min)

Max.

ball No

(t)

Feed size(m)

Output size(mm)

Capacity(t/h)

Power

(kw)

Weight

(t)

YMQ750×1800

39

1.0

0-15

0.075-0.3

0.3-0.8

11

3.5

YMQ900×2100

37.8

1.5

0-15

0.075-0.3

0.8-2.1

15

5.2

YMQ1200×2800

37

5.2

0-20

0.075-0.3

1.2-6.2

30

10

YMQ1500×3500

29.7

8.0

0-25

0.075-0.3

2.8-9

75

17

YMQ1500×4500

29.7

9.5

0-25

0.075-0.3

2.8-10

90

20

YMQ1830×3600

25

11.5

0-25

0.075-0.3

5.2-25

130

28

YMQ1830×4500

25

16.5

0-25

0.075-0.3

5.2-30

155

32

YMQ2100×3600

24.6

17.4

0-25

0.075-0.3

6.5-40

180

41

YMQ2100×4500

24.6

22.5

0-25

0.075-0.3

6.5-42

210

46

YMQ2400×3600

22.4

23

0-25

0.075-0.3

7.2-92

210

65

YMQ2400×4500

22.4

28.5

0-25

0.075-0.3

7.2-95

245

72

YMQ2700×3600

20.7

40

0-25

0.075-0.3

12-145

320

80

YMQ2700×4500

20.7

50

0-25

0.075-0.3

12-155

380

90

Description

Ball Mill save energy and high capacity is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grind-able materials

Features

1) Gold ore processing machine is an efficient tool for grinding many materials into fine powder;

2) The gold ore processing machine is used to grind many kinds of mine and other materials, or to select the mine;

3) Gold ore processing machine is widely used in building material, and chemical industry.

4) There are two ways of grinding: the dry way and the wet way.

5) Gold ore processing machine can be divided into tabular type and flowing type according to different expelling mine

6) To use the gold ore processing machine, the material to be ground is loaded into the neoprene barrel that contains grinding media.

7) As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

8) The longer the ball mill runs, the finer the powder will be.

9) Ultimate particle size depends entirely on how hard the material you're grinding is, and the time how long the ball mill runs.

10) Our ball mills have been used to grind glass, powder food products, create custom varnishes, make ceramic glaze, powder various chemicals

Working Principle of ball mill:

The ball mill is horizontal cylindrical rotation device, driven by brim gearwheel. There are two chambers and grid of ball mill. Material goes into the first chamber through the feeding inlet. Inside the first chamber, there are stage liners and ripple liners as well as steel balls. The ball mill shell rotates so as to generate electricity, and this force brings ball to a certain height and then balls drop down by gravity, the impact is the grinding force to the material. After the primary grinding, materials go into the second chamber through segregate screen. In ball mill second chamber, there are flat liners and steel ball. After the secondary grinding, material is discharged from the discharging mouth. Then the whole grinding process is ended.

Technical data

Model

Rotate Speed (r/min)

Max.

ball No

(t)

Feed size(m)

Output size(mm)

Capacity(t/h)

Power

(kw)

Weight

(t)

YMQ750×1800

39

1.0

0-15

0.075-0.3

0.3-0.8

11

3.5

YMQ900×2100

37.8

1.5

0-15

0.075-0.3

0.8-2.1

15

5.2

YMQ1200×2800

37

5.2

0-20

0.075-0.3

1.2-6.2

30

10

YMQ1500×3500

29.7

8.0

0-25

0.075-0.3

2.8-9

75

17

YMQ1500×4500

29.7

9.5

0-25

0.075-0.3

2.8-10

90

20

YMQ1830×3600

25

11.5

0-25

0.075-0.3

5.2-25

130

28

YMQ1830×4500

25

16.5

0-25

0.075-0.3

5.2-30

155

32

YMQ2100×3600

24.6

17.4

0-25

0.075-0.3

6.5-40

180

41

YMQ2100×4500

24.6

22.5

0-25

0.075-0.3

6.5-42

210

46

YMQ2400×3600

22.4

23

0-25

0.075-0.3

7.2-92

210

65

YMQ2400×4500

22.4

28.5

0-25

0.075-0.3

7.2-95

245

72

YMQ2700×3600

20.7

40

0-25

0.075-0.3

12-145

320

80

YMQ2700×4500

20.7

50

0-25

0.075-0.3

12-155

380

90