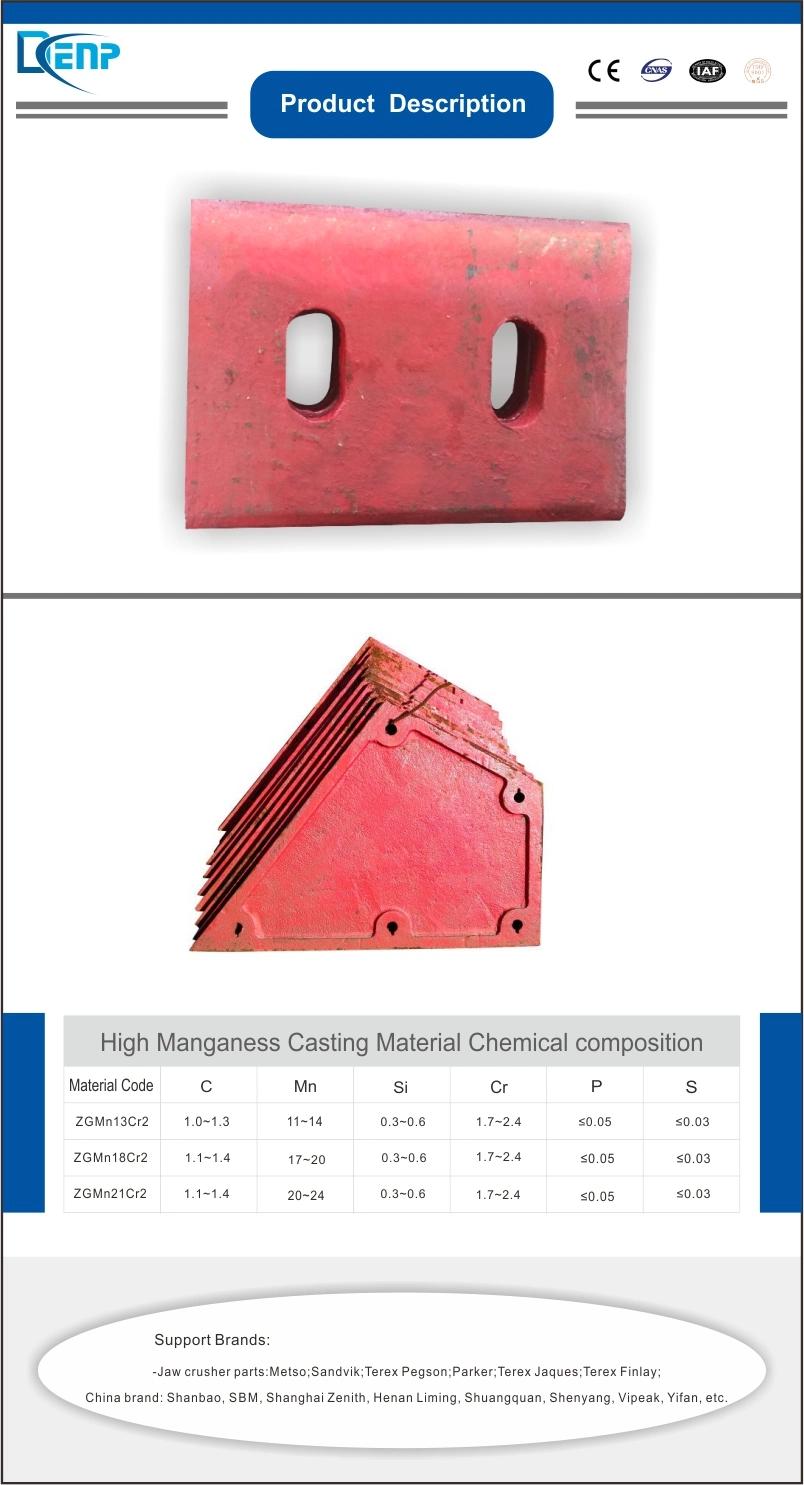

High Manganese Side Plate with Chrome Used by Jaw Crusher

Shenzhen DENP Industrial Co., Ltd.- Certification:ISO 9001:2000, ISO 9001:2008

- Standard:GB, ASTM

- Surface Treatment:Polishing

- Manufacturing Process:Casting

- Material:High Manganese

- Hardness:180-220hb

Base Info

- Model NO.:Shanbao

- Mn Content:13%Mn

- Package:Wooden Tray or Iron Pallet

- Usage:Jaw Crusher

- Transport Package:Wooden Tray

- Specification:GB

- Trademark:DP

- Origin:China

- HS Code:84742090

- Production Capacity:5000t,Y

Description

Basic Info.

Model NO. Shanbao Mn Content 13%Mn Package Wooden Tray or Iron Pallet Usage Jaw Crusher Transport Package Wooden Tray Specification GB Trademark DP Origin China HS Code 84742090 Production Capacity 5000t/YProduct Description

High Manganese Side Plate with Chrome Used to Jaw CrusherSide plate is the wear parts of jaw crusher. We use high manganese steel with chrome as the material to make sure best quality Jaw Crusher Side Plate.

When stones or mineral ores are fed to crushing cavity, many of they will impact the two sides of main-frame of jaw crusher, as a result, the main frame may be abraded without any protection. While, side plate / liners can prevent it from being abraded well when they are installed and extend the service-life of jaw crusher greatly.

DENP Industrial is expert of Jaw Crusher Side Plate. We get very good reputation from our customers feedback in the past 10 years. And we make sure all the Jaw Crusher Side Plate export by DENP Industrial in stable quality in high level.

As primary crushing unit, jaw crusher is most popular crusher unit in the whole crushing plant. DENP Industrial focus on various jaw crusher side plate in stock for customers to choose. We can supply jaw plate, side plate, toggle plate, toggle seat, adjustment seat, swing jaw, shaft, bearing, V-belt, bolts&nuts, and so on. And our jaw die match most of Chinese brand crushers such as Shanbao, SBM, Zenith, Liming, DongMeng, FTM, Yifan, Vipeak and so on.

Also we can match the parts number for famous crusher brand in International such as Metsoo/Sandvik/Terex/Symons and so on. You welcome to visit us choose your ideal wear parts for your crushers.

| Material | C | Mn | Si | Cr | P | S |

| Mn13Cr2 | C:1.0~1.3 | Mn:11~14 | Si:0.3~0.6 | Cr:1.7~2.4 | P:≤0.05 | S:≤0.03 |

| Mn18Cr2 | C:1.1~1.4 | Mn:17~20 | Si:0.3~0.6 | Cr:1.7~2.4 | P:≤0.05 | S:≤0.03 |

| Mn21Cr2 | C:1.1~1.4 | Mn:20~24 | Si:0.3~0.6 | Cr:1.7~2.4 | P:≤0.05 | S:≤0.03 |

FAQ:

Is your company an OEM factory or a trading company?

We are the manufacturer of wear parts for crushers to provide wear-resistant parts to many well-known enterprises at home and abroad. Welcome to visit our factory, we will become your excellent supplier.

Quality?

Stable high-end products,DENP brand parts are high-quality products.

Shipment?

Try to ensure delivery a 20GP within 40 days. If the order is particularly urgent, it depends on the production plan at the time.

Payment?

30% T/T advanced and the balance of 70% T/T before shipping.

How much is the remaining capacity of your plant?

On the one hand, we are working hard to increase the actual production capacity to reach the theoretical capacity target of 10,000 tons per year. On the other hand, we are adjusting the production plan to try to meet the demand for quality distributors like you.

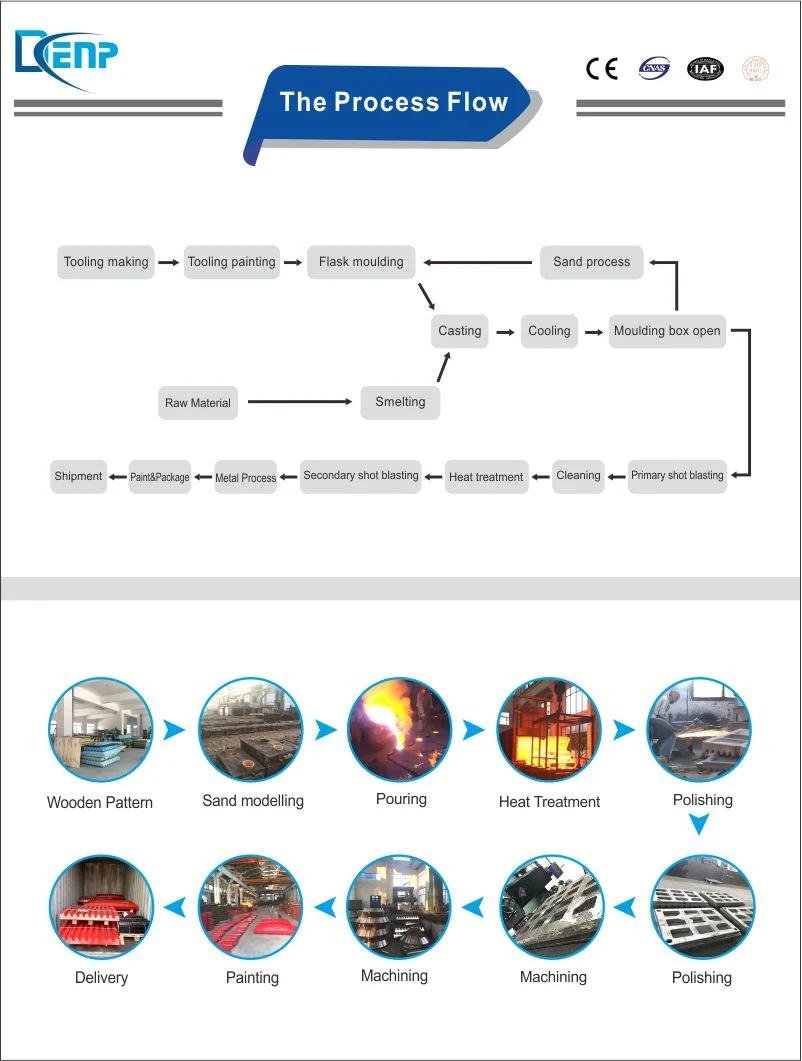

Why do you use a fine sand recycling system in your factory? How is your surface treated to ensure a good appearance?

The fine sand recycling system ensures that we always use the highest quality fine sand and cooperate with two shot blasting treatments to minimize the appearance defects and give our customers a better sensory experience.

It is difficult to produce for small items (products below 100kg) and the delivery period is long.

Our main products are 200kg-6000kg. The cost of small parts is high, and small parts are generally used to help customers piece together a container. Because there is no special equipment for small parts, it needs to be put together according to the production plan and other products, so the production cycle will be a bit long.

Please inform the nearest airport or train station from your factory.

Airport: YIWU AIRPORT(45 minutes by car); Train station: JINHUA RAILWAY STATION (25 minutes by car)