Professional Manufacturer of Spiral Sand Washing Machine

Luoyang Zhongtai Industries Co., Ltd.- Type:Bucket Sand Washer

- Capacity:150-200t,h

- Water Consumption:20-60t,h

- Speed of Screw:18rpm

- Motor Type:DC Motor

- Motor Power:7.5KW

Base Info

- Model NO.:sand washing machine

- Certification:ISO

- Rotation Speed:0.8-1.5 r,min

- Wheel Bucket Diameter:2800mm

- Screw Diameter:1000mm

- Warranty:a Year

- After-sales Service:Twenty Four Hour Online

- Sand Washer:Xs Series Wheel Sand Washer

- Total Weight(Kg):8100

- Processing Capacity(T/H):15-200

- Transport Package:Xs Series Wheel Sand Washer

- Specification:XS Series Wheel Sand Washer

- Trademark:ZTIC

- Origin:Luoyang, Henan

- HS Code:8438600000

- Production Capacity:500PCS,Year

Description

Sand Washer: XS Series Wheel Sand Washer

Supply Ability:100 Set/Sets per Month

Certificate:ISO9001:2008

Production capacity:15-200t/h

Feature:Simple structure, stable operation

The XS Series Wheel Sand Washer is the washing equipment for artificial sand, can be divided into two types: XS type and XL type. It can remove the impurities that cover in gravel surface, while undermining the vapor layer which coats sand, so that facilitate dehydration and play an efficient sand washing and cleaning effect, therefore, it is widely used in gravel pits, mining, building materials, transportation, chemical industry, water conservancy and hydropower and concrete mixing station to wash materials.

Working principle:

When sand washing machine is working, the motor drives impeller running slowly through V-belt and reducer; the sand are fed from feed trough to wash tank, then roll driven by impeller and grind each other to remove the impurities that cover in gravel surface and undermine the vapor layer that coats sand, so that facilitate dehydration; meanwhile, add water to form strong currents to timely take away impurities and foreign body of small proportion and discharge them from outlet. The clean gravels are taken away by the blades and poured by the rotation of impeller into the discharge chute to complete the entire cleaning action.

XS Series Wheel Sand Washer Structural features

1, simple structure, stable operation.

2, bearings are separated from water and materials, avoiding machine prematurely causes damage phenomenon due to rust.

3, wide range of application.

4, less material loss, high washing efficiency, can fully meet the requirements of high-grade materials.

5, long service life.

6, less maintenance, greatly reducing the cost.

XS Series Wheel Sand Washer Technical Data

XS2200

XS2600

XS2900

XS3500

Wheel bucket diameter(mm)

2200

2600

2900

3500

Rotation speed(r/min)

1-2

1-2

0.8-1.5

0.8-1.2

Processing capacity(t/h)

15-30

20-50

50-100

120-200

Motor power(kw)

4

5.5

7.5

11

Total weight(kg)

4300

5600

8100

9900

Dimensions (L*W*H) (mm)

3150*1910*2280

3520*2390*2690

3820*2640*3200

4420*2930*3800

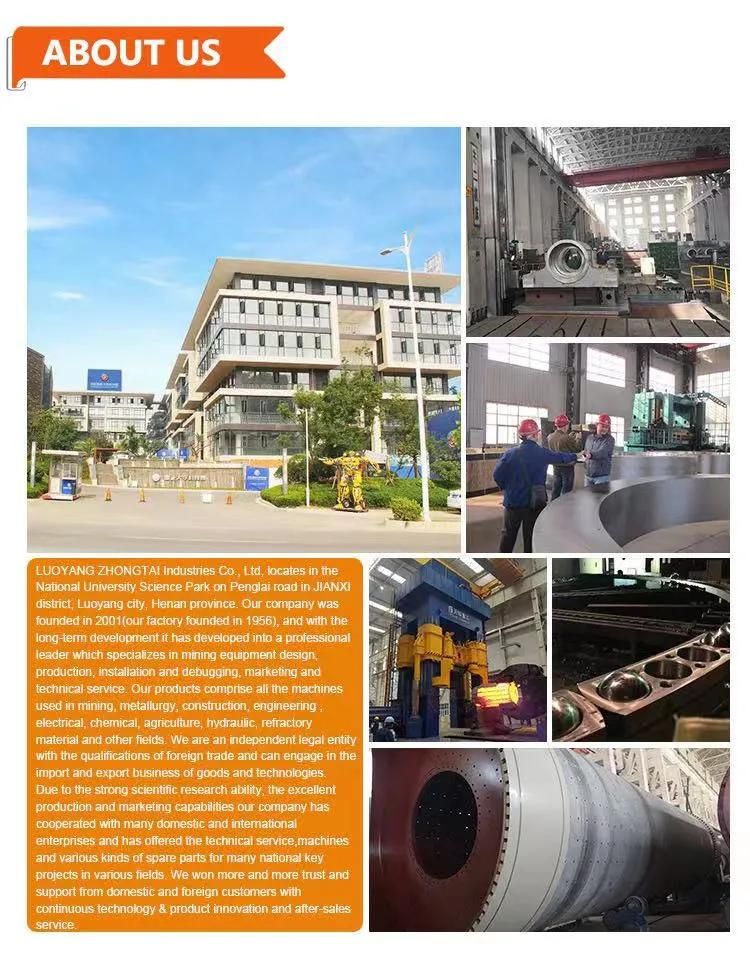

Company Information

After Sales Service

After Sales ServiceFAQ

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time

A: parts lead time 1-2months, machines 2-3months.

Q:Payment terms

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping

Q: Quality warranty?

A: guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: we can supply technical guide for machines running test and parts maintenance if end user needs.