Gold Processing Plant Concentrator Washing Machine Drum Washer

Jiangxi Province County Mining Machinery Factory- Power:45 Kw

- Processing Capacity:150-180tph

- Angle of Inclination:=<10 Degree

- Feeding Size:=<230 mm

- Rotation Speed:16 R,Min

- Screen Size:=<50 mm

Base Info

- Model NO.:1800

- Guarantee:1-3 Years

- After-Sales Service:Overseas Engineers Guidance

- ODM&OEM:Accepted

- Mobile&Fixed:Available

- Related Products:Trommel Screen,Shaking Table,Jig Separator,etc.

- Transport Package:Shipping by 1X40′hq or Flat Container

- Trademark:JXSC

- Origin:Ganzhou, Jiangxi

- Production Capacity:200sets,Month

Description

Basic Info.

Model NO. 1800 Guarantee 1-3 Years After-Sales Service Overseas Engineers Guidance ODM&OEM Accepted Mobile&Fixed Available Related Products Trommel Screen,Shaking Table,Jig Separator,etc. Transport Package Shipping by 1X40′hq or Flat Container Trademark JXSC Origin Ganzhou, Jiangxi Production Capacity 200sets/MonthProduct Description

Trommel Scrubber Washing Machine Application

Trommel Scrubber Washing Machine is one of our best selling gravity equipments.It is suitable to wash and sieve all kinds of materials that with sticky clay, such as alluvial gold / tin ore/ tungsten ore/ chrome ore/ coltan ore/ beach sand/ zircon sand/ diamond/iron sand/manganese ore/silica sand/ kaolin clay/ gravel stone,ect.

Below are some on-site photos from our customeres in different countries.

We have professional engineers team to draw flowchart based on customer's gold mine site details.

We supplied full set gold plant: vibrating feeder, trommel scrubber washing machine, gold centrifugal concentrator, sluice box and shaking table.

Trommel Scrubber Washing Machine Introduction

Trommel Scrubber is a main washing equipment in mining industrial, widely used for washing alluvial type/sand type ores and stones that with much sticky clay.It has much good washing effect for clay.

This machine with two parts: drum scrubber and screen. The drum scrubber is for washing ore, screen is for sieving different size particles after washing.

Washing Trommel Scrubber Screen Material

1. Manganese steel: normal material, not easy to replace, 2-3 monthes life time.

2. PU material: wear-resistance, long life time 4-6 monthes, corrosion resistant, splicing technology, replacable, very easy to replace.

3. Stainless steel material : wear-resistance, long life time 4-6 monthes, corrosion resistant, splicing technology, not easy to replace.

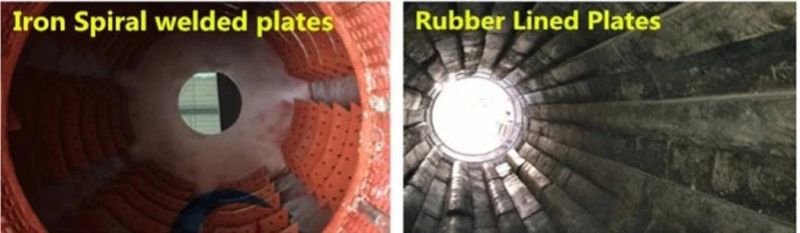

Washing Trommel Scrubber Linning Plate

In order to increase the washing effect, we always put linning plates insider of the drum scrubber part, it can be made of the following two kinds material:

1. Iron material spiral plates: normal material, can't be replaceable, welded inside drum.

2. Natural Rubber lined plates: wear-resistance, long life time, corrosion resistant, fixed with screw, replacable, easy to replace.

Rotary Scrubber Washer Main structure

1. Drum scrubber : For washing the clay.2. Trommel scrubber Inner plate: separating the clay and ores, washing clay to be more clean.

3. Trommel scrubber Sieving screen: for sieving different sizes ores, the screen mesh size& layer quantity & screen materials can be customized according to customer need.

4. Diamond washing trommel scrubber Motor: electric or diesel according to your needs.

5. Carrier rollers: For support the drum

6. Gear, Reduction Box, coupling.

7. Machine Frame: Supporting the reduction box and motor.

Trommel Scrubber Washing Machine Technical Parameters

| Model | Screen Size (MM) | Rotation Speed(R/Min) | Feeding size (mm) | Angle of inclination (degree) | Capacity (T/H) | Power (KW) |

| JXSC-400 | ≤20 | 27.9 | ≤80 | ≤10 | 1-5 | 3 |

| JXSC-600 | ≤25 | 27.6 | ≤80 | ≤10 | 5-10 | 5 |

| JXSC-750 | ≤25 | 27.6 | ≤100 | ≤10 | 10-30 | 7.5 |

| JXSC-900 | ≤25 | 27.6 | ≤100 | ≤10 | 30-50 | 11 |

| JXSC-1200 | ≤25 | 17 | ≤160 | ≤10 | 50-70 | 15 |

| JXSC-1500 | ≤50 | 16 | ≤230 | ≤10 | 70-100 | 30 |

| JXSC-1800 | ≤50 | 16 | ≤230 | ≤10 | 100-150 | 37 |

| JXSC-2100 | ≤50 | 16 | ≤230 | ≤10 | 150-180 | 45 |

Related Products

Packaging & Shipping

Minerals Washing Trommel Scrubber Packing/Loading

1.Gold Washing Scrubber spare parts would be packed in wooden boxes to avoid broken.

2. Gold Washing Scrubber are fixed and loaded in container directly.

Minerals Washing Trommel Scrubber Shipping

1. Gold Washing Scrubber are shipped in Flat Containers by sea.

2. Gold Washing Scrubber can be also shipped by air if customers request.

About us

Jiangxi Shicheng Mine Machinery Factory is an experienced supplier of complete set mining equipments, professional at providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore / Diamond/ Coltan ore / Silica sand / Zircon sand/ Black sand/Chrome ore, ect. As well as complete set small lab mining machines.

Our Core Advantages as below :

1.+30 years history FACTORY at mining machinery

2.Provide engineer team after sales service

3.Provide Complete set mineral processing plant

4.Provide Sample testing service in factory lab for free

5.Provide professional Mining Solution Consulting

JXSC Main products including: trommel screen, trommel scrubber, shaking table, spiral chute separator, jig machine, centrifugal concentrator, sluice box, vibration screen, melting furnace, jaw crusher, hammer crusher, ball mill, flotation machine, spiral classifier. as well complete set small laboratory mining equipments

JXSC Mine Machinery Factory main markets

Africa, South Amercia, Europe , Southeast Asia, Asia,ect. Our cooperated customers cover Mali, Ghana, Sudan , Uganda, Mozambique, Suriname, Zambia, Nigeria, Cameroon, Madagascan, Malasia, Indonesia, Korea, Philippines, Monglia, Singapore, Inida, Iran, Mexico, Brazil, Chile, Peru, Spain, Canada, Austrilia,U.S, UAE,ect.

Our Exhibition

Our service

Pre-Sales Service

*Inquiry and consulting support*Ore sample testing support

*View our Factory

*Design Flowchart

After-Sales Service

* Training how to instal the machine, training how to use the machine.* 1 year warranty

* Engineers available to service machinery overseas.

FAQ

1.How is the quality of your products? (mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

ContactsIf you are interested in our products, please don't hesitate to contact us. You can tell me the following questions, so that we can send you accurate quotation soon, including extra discounts!

1. Which machine do you need? like gold washing machine, spiral chute, vibrating screen, Jig separator, Shaking table, etc.

2. What is your raw material plan to process? like gold ore, diamond ore, tantalite ore or iron ore, etc.

3. The capacity you need? Like 100 tones per hour.

4. Your contact information? Both Email and phone number are essential, we can contact you easier.