Automatic Control System Hydraulic Cone Crusher

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Type:Cone Crusher

- Motor Type:AC Motor

- Motor Power:22kw

- Application:Mine

- Materials:Limestone

- Outlet Size:18-48mm

Base Info

- Model NO.:hpt-500

- Inlet Size:300×1300mm

- Condition:New

- Name:Manganese, Iron, Chromium Mining Hydraulic Cone Cr

- Keywords:Cone Crusher

- Color:Customization

- Material:Carbon Steel

- Transport Package:Nude Packing

- Specification:2.3*1.5*2.5m

- Trademark:hc

- Origin:China

- Production Capacity:2000,Year

Description

630(850)C2 Coarse 300 32 495-1050 M Medium 265 25 470-950 F1 Fine 220 17 385-730 F2 Extra Fine 150 14 310-600 F3 Extra Fine 90 10 260-550

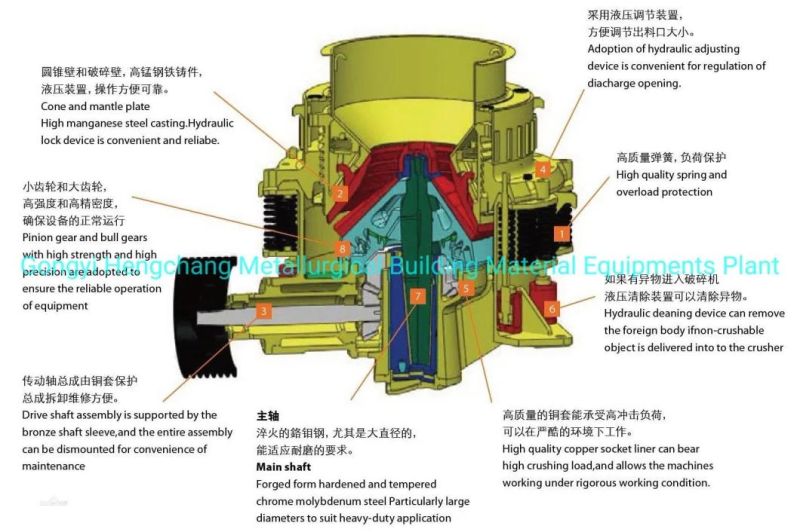

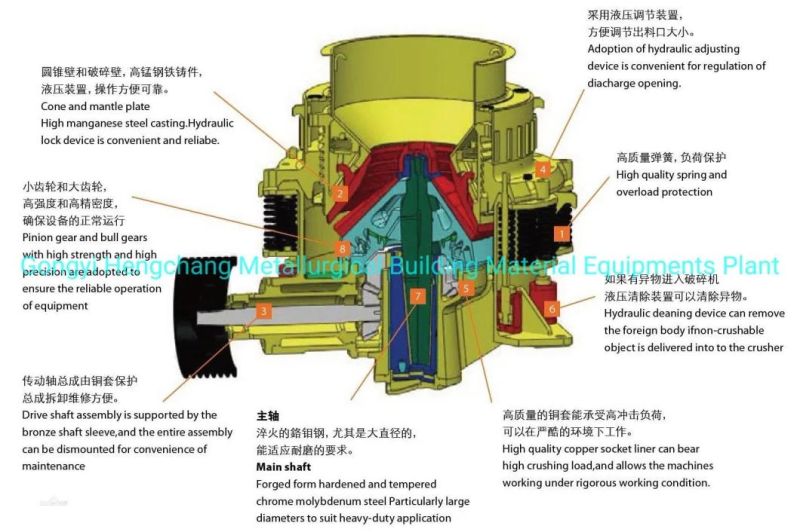

working principle

The multi-cylinder cone crusher is a typical crushing device for medium and fine crushed hard materials. When working, the moving cone makes a swinging motion along the inner surface. Near the fixed cone, the material is crushed by the extrusion and bending of the moving cone. When the moving cone is offset, the broken material falls from the bottom of the cone due to gravity. The crushing and discharging processes are successively performed sequentially along the inner surface. The lock protection cylinder is composed of a plurality of lock protection cylinders, an over-iron protection accumulator, a buffer accumulator group and a pipeline. The locking protection cylinder mainly functions as iron protection and cleaning the crushing chamber. Each two hydraulic cylinders are equipped with a buffer accumulator. When the normal crushing is used, the adjusting ring jumps due to a few hard materials during the buffering.

The multi-cylinder hydraulic cone crusher is realized by hydraulic device because of its insurance, adjustment and locking. Therefore, it has the following characteristics like the single-cylinder hydraulic cone crusher: it is convenient to adjust the discharge port, and the overload factor is small when passing through non-broken objects. It is easy to take out non-broken objects that are clogged in the crushing chamber. Production practice shows that this hydraulic cone crusher has good performance. However, compared with a single cylinder, the crusher has a complicated structure and a manufacturing man-hour is higher than a single cylinder.

The spring hydraulic cone crusher has a hydraulic system to adjust the size of the crusher discharge port, and the hydraulic system can effectively ensure the safe operation of the equipment. When there is foreign matter in the crushing chamber, the hydraulic system can automatically lower the moving cone. When the foreign matter is discharged, the system automatically resets the falling moving cone. Re-maintain the original discharge port position and continue to work.

(1) Increase the eccentric moment and improve the processing capacity;

(2), speed up, increase power, increase the fineness of crushing;

(3), raise the moving cone selection center, optimize the cavity design;

(4) Thickening of the lining plate to extend the life;

(5), the hydraulic motor replaces the hydraulic push rod device, and the fixed cone assembly is removed in 10 minutes;

(6) High production and mineral content;

(7), the key components are made of high-strength materials, and the weight is increased appropriately, and the reliability is higher.

working principle

The multi-cylinder cone crusher is a typical crushing device for medium and fine crushed hard materials. When working, the moving cone makes a swinging motion along the inner surface. Near the fixed cone, the material is crushed by the extrusion and bending of the moving cone. When the moving cone is offset, the broken material falls from the bottom of the cone due to gravity. The crushing and discharging processes are successively performed sequentially along the inner surface. The lock protection cylinder is composed of a plurality of lock protection cylinders, an over-iron protection accumulator, a buffer accumulator group and a pipeline. The locking protection cylinder mainly functions as iron protection and cleaning the crushing chamber. Each two hydraulic cylinders are equipped with a buffer accumulator. When the normal crushing is used, the adjusting ring jumps due to a few hard materials during the buffering.

The multi-cylinder hydraulic cone crusher is realized by hydraulic device because of its insurance, adjustment and locking. Therefore, it has the following characteristics like the single-cylinder hydraulic cone crusher: it is convenient to adjust the discharge port, and the overload factor is small when passing through non-broken objects. It is easy to take out non-broken objects that are clogged in the crushing chamber. Production practice shows that this hydraulic cone crusher has good performance. However, compared with a single cylinder, the crusher has a complicated structure and a manufacturing man-hour is higher than a single cylinder.

The spring hydraulic cone crusher has a hydraulic system to adjust the size of the crusher discharge port, and the hydraulic system can effectively ensure the safe operation of the equipment. When there is foreign matter in the crushing chamber, the hydraulic system can automatically lower the moving cone. When the foreign matter is discharged, the system automatically resets the falling moving cone. Re-maintain the original discharge port position and continue to work.

(1) Increase the eccentric moment and improve the processing capacity;

(2), speed up, increase power, increase the fineness of crushing;

(3), raise the moving cone selection center, optimize the cavity design;

(4) Thickening of the lining plate to extend the life;

(5), the hydraulic motor replaces the hydraulic push rod device, and the fixed cone assembly is removed in 10 minutes;

(6) High production and mineral content;

(7), the key components are made of high-strength materials, and the weight is increased appropriately, and the reliability is higher.