Industrial Dry Material Conveyor Cleaning Brush Belt Cleaner Roller

JIAOZUO DEBON TECHNOLOGY CO., LTD.- Type:Material Handling Conveyor

- Structure:Belt Conveyor

- Material:Nylon Bristle + Steel Pole + Emd

- Material Feature:Wear Resistant, Durable, High Quality

- Certification:ISO9001:2008, ISO9001:2000, CE, SGS

- Energy Saving:Energy Saving

Base Info

- Model NO.:DB-XQ-I

- Warranty:1 Year

- Color:Multi Color

- Customized:Customized

- Condition:New

- After-sales Service:Provide

- Advantage:23 Years Manufacturer, 11 Year Exportor, Advanced

- Item Name:Industrial Dry Material Conveyor Cleaning Brush Be

- Keyword:Brush Belt Cleaner Roller

- Application:Aggregate, Coal Mine, Sand, Gravel, Dry Material

- Function:Clean Residual Carryback, Remove Sticky Material

- Feature:Wear Resistant Bristle, High Performance Cleaning

- Benefits:Replaceable Brush Bristle, Each Installation

- Install:Under Return Belt

- Description:Keep Conveyors Running Efficiently and Consistentl

- Component:Brush Bristle, Steel Pole, Electric Motor

- Certificates:ISO CE SGS Safety Certificate of Approval for Mine

- Type of Belt Cleaner:Conveyor Brush Belt Cleaner

- Belt Width:500-2000mm

- Material Humidity:<5%

- Handle Material:Dry and Fine Material

- Transport Package:Crate, Wooden Case

- Specification:as required

- Trademark:Jiaozuo Debon

- Origin:China

- HS Code:8431390000

- Production Capacity:500 Sets, Week

Description

Basic Info.

Model NO. DB-XQ-I Warranty 1 Year Color Multi Color Customized Customized Condition New After-sales Service Provide Advantage 23 Years Manufacturer, 11 Year Exportor, Advanced Item Name Industrial Dry Material Conveyor Cleaning Brush Be Keyword Brush Belt Cleaner Roller Application Aggregate, Coal Mine, Sand, Gravel, Dry Material Function Clean Residual Carryback, Remove Sticky Material Feature Wear Resistant Bristle, High Performance Cleaning Benefits Replaceable Brush Bristle, Each Installation Install Under Return Belt Description Keep Conveyors Running Efficiently and Consistentl Component Brush Bristle, Steel Pole, Electric Motor Certificates ISO CE SGS Safety Certificate of Approval for Mine Type of Belt Cleaner Conveyor Brush Belt Cleaner Belt Width 500-2000mm Material Humidity <5% Handle Material Dry and Fine Material Transport Package Crate, Wooden Case Specification as required Trademark Jiaozuo Debon Origin China HS Code 8431390000 Production Capacity 500 Sets/ WeekProduct Description

Why Choose Us:We are professional manufacturer of belt conveyor components and related products. We produce various kinds of belt cleaner, belt sealing skirting, pulley lagging, ceramic rubber liner,etc, to meet different applications, custom size and structure are available.

We will be your reliable partner and supplier.

1. Over 20 years experience in wear products and conveyor accessories.

2. Over 10 years experience in exporting, UK, France, Chile, Canada, USA, Finland, Australia, Russia, Indonesia, Thailand, etc.

3. SGS audited supplier.

4. ISO9001:2015 certified factory.

5. Strict QC/QA makes sure high quality and consistency.

Products Description

Industrial Dry Material Conveyor Cleaning brush belt cleaner roller

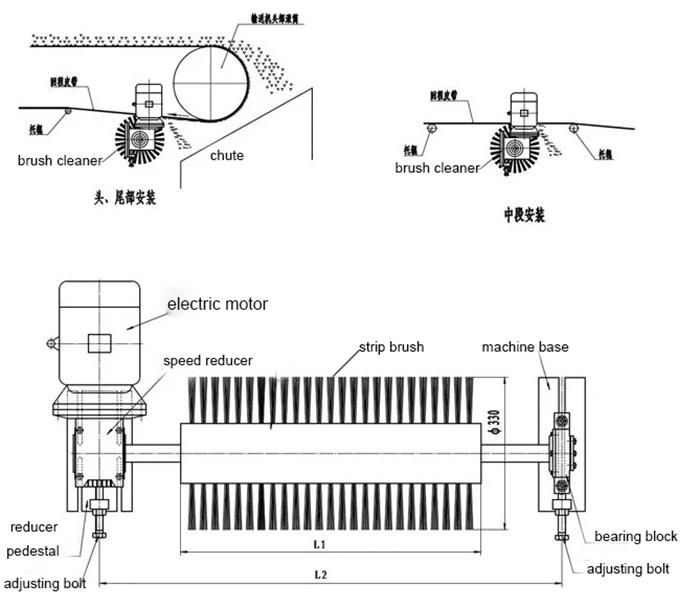

Conveyor brush belt cleaner DB-XQ-I is a motorized brush belt cleaner installed under the return belt of the conveyor, tips of the cylindrical nylon brush touch the belt surface gently. The rotating brush turns in the opposite direction of the belt and brushes away the sticky materials into the funnel.

New brush belt cleaners feature replacement brush strips, total 12 brush strips, easy installation, and you just need remove worn strips and insert new strips.

Application

1. Belt Width: 500~2000(mm)

2. Material humidity: ≤5%

3. Applicable for ribbed, plain, grooved or chevron conveyor belts.

4. Working temperature: -40~90 C

5. Suit for all kinds of belt speed

6. Handled material: dry and fine material

conveyor belt brush cleaner applys to aggregate, sand and gravel, pulp/paper, wood chips, cement, coal, scrap metal, chevron/cleated belts.

Specification and Installation of Industrial Dry Material Conveyor Cleaning Belt Brush Cleaner For Conveyor:

Features of Industrial Dry Material Conveyor Cleaning brush belt cleaner roller:

1. Replaceable brush bristles: Brush strips/bristles are replaceable, just remove worn strips and insert new strips, no need replace whole brush roller, very cost-efficient.

2. Adjustable: easily adjust brush to belt as bristles wear.

3. Spiral brush cleaner uses 1.5mm nylon 66 bristles wrapped in spiral around the hub

4. Custom voltage and power of motor and reducer.

5. Uniquely nylon66 brush bristles-aids in reducing material buidup and clogging

6. Works on mechanically spliced or vulcanized belts

7. Maximum cleaning- spins opposite the belt direction for optimal cleaning

Easy replacement and installation and maintenance.

Food grade brush belt cleaner.

Main Products

PRODUCTS & SERVICES

* Conveyor Systems & Accessories Conveyor Belt Scrapers/Cleaners

* Conveyor Skirting Rubber / Polyurethane

* Ceramic Rubber Wear Liners

* Linings, Coatings, Insulation & Corrosion Protection

* Mill Liners

* Ceramic Rubber Pulley Lagging

* Impact Bed/bars

* Steel Cord Stripper

* Other rubber and polyurehtane products

Company Information

23 Year Manufacturer:

Jiaozuo Debon Technology Co., Ltd., whose former name is Jiaozuo Zhuoer Machinery Manufacturing Co., Ltd, founded in 1996, with 126 employees, including 35 engineers, we are manufacturer specialized in designing and manufacturing Industrial Conveyor Belt Related Products.

11 Year Exportor:

Our products have been exported to many countries: Australia, Chile, USA, Russia, UK, Canada, France, New Zealand, Jordan, South Africa, Indonesia, Thailand, Vietnam, etc., good quality have be approved by our clients.

Our company is certified to ISO 9001:2008 Quality Management System, and rubber lagging products were certified to "SAFETY CERTIFICATE OF APPROVAL FOR MINING PRODUCTS". We are ISO SGS approved manufacturer, SGS audited supplier, ISO9001 certified factory.

Our products are exported to many countries including America, Canada, Australia, Russia, Kazakhstan, Chile Southeast Asia, etc.

We also have good performance and market share in domestic market. Our customers prove the high quality and consistency.

Certificate Industrial Dry Material Conveyor Cleaning brush belt cleaner roller

Industrial Dry Material Conveyor Cleaning brush belt cleaner roller