Dragon Large Tug Boat with Two Engines

Weifang Dragon Machinery Technology Co., Ltd.- Type:Tug Boat

- Power Type:Diesel

- Customized:Customized

- Condition:New

- Warranty:One Year

- After-sales Service:One Year

Base Info

- Model NO.:DGWB2022

- Installed Power:700 HP, Single Propeller

- Sailing Speed:20 Knots

- Fuel Transportation Capacity:40 Tons

- Colour:OEM

- Draft:1.0

- Hull:18*6*2

- Main Engine:Famous Brand Engine

- Steel Plate Thickness:8 mm

- Transport Package:Naked Outfit

- Specification:customized

- Trademark:Dragon

- Origin:China

- HS Code:8905100000

- Production Capacity:50 Sets,Year

Description

Main Specifications Length Overall 14.0m Beam Max 4.2m Moulded Depth 1.6m Draft 1.0m Main Engine Cummins, 1 set, 300Hp Standby Generator Sunvim, 1 set, 10kw Supplying Electrcity Steel Plate Thickness Main deck: 6 mm

Front plate: 6 mm

Side plate: 6 mm

Back plate: 6 mm

Bottom: 8 mm New steel plate Power System Main Engine Quantity: 1 set

Brand: Cummins

Model:NT855-M

Power: 300 hp

Cooling: water Driving the propeller through gearbox Gearbox Quantity: 1 set

Brand: Hangzhou Advance

Model: 300

Rated Input Power: 500 kw Deck Layout Towing Post Quantity:1 piece

Diameter:300 mm

Towing Capacity: 200 Kn

Position: end of the boat Bollard Quantity: 4 pairs

Diameter: 150 mm

Height: 350 mm Anchor Crane & Winch Quantity: 1 set

Type: A Frame Crane

Winch Capacity: 4 tons Operating Room Operation Panel: 1 set, arranged all the operation button and switch

Pilot chair: 1 set, adjustable

Magnetic compass: 1 set

Fan: 1 set Ventilation Hole On the engine room and fuel tank Rudder System Steering Gear Quantity: 1 set,

Composition: helm, hydraulic cylinders, hydraulic valves, angle gauge, pull rod. Controlled from the operation cabin through helm Rudder Quantity: 1 piece, action is controlled by steering gear. Propeller Quantity: 1 piece

Diameter: 900 mm

Material: copper alloy

Driving through horizontal shaft The shaft is cooled by moving oil

Manufacturing Ability

Our factory is equipped with all kinds necessary manufacturing facility, including CNC cutting machine, welding robot, digital controlled lathes, machining center, milling machine, grinding machine, punching machine, and surface handling line. With all these facility, we can complete all the kinds of machining work, plate welding, finishing and painting.

After-sale Service

DRAGON customers rely on the unrivalled level of commitment that is offered to them through dedicated and comprehensive life-cycle support services. These help to maximise the equipment's availability and the return on investment, and therefore reduces the total cost of ownership. The cycle can be entered at any of its integrated stages.

DRAGON supplies high-quality and up-to-date training services for the site operation people to ensure that crews operate the dredger in a highly skilled and efficient manner to achieve optimum levels of productivity. DRAGON life-cycle support also allows operators to maintain the durability and reliability of their systems through a range of specialist services.

DRAGON team wants to be prepared for every eventuality and provide limitless logistical support to its customers.This includes attention to system availability with the immediate supply of spare parts and repair of components.With this approach, the complete DRAGON global network of qualified service technicians,sourcing officers and local service offices is available to all customers.

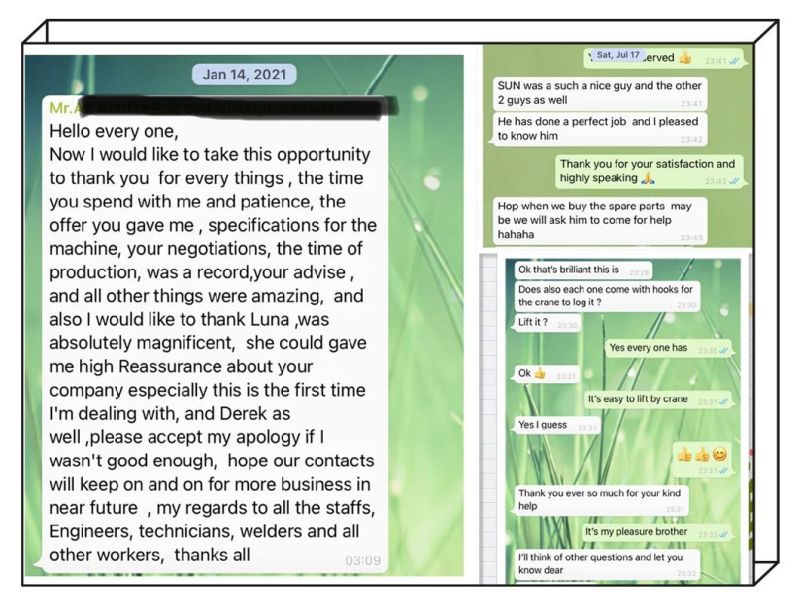

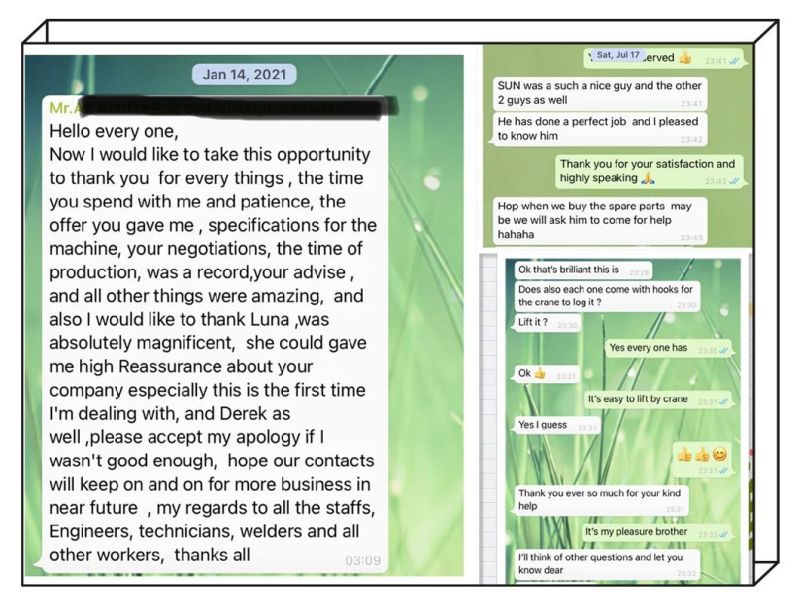

Customer Feedback

Customer Feedback

Why You Choose Dragon Dredger

1. Advanced Design

2. Advanced Equipment and Quality

3. Creative Design and Layout

4. Considerate Service and Training

5. Competitive Price

6. Extended Warranty

7. Performance Guarantee

8. Bring Other Cooperation Opportunities

Other Products

Dragon products scope covers all kinds of dredger, aquqtic weed harvester, amphibious excavator, workboat, backhoe barge, jack-up platform.

FAQ

Q1: Do you have your own factory?

:A1: Yes, our parent company is Weifang Dragon Machinery Technology Co.,Ltd., it is specialized in manufacturing dredgers and amphibious excavators and other machineries.

Q2: Can we visit your factory?

A2: Sure, we sincerely welcome you to visit and check our factory, we would show you around of our workshop.

Q3: Do you also supply the accessories of dredgers?

A3: Yes, we have cooperated companies to supply you the accessories and other spare parts.

Q4: Do you have aftersale service center overseas?

A4: Yes, we have aftersale service center in Nigeria which will cover Africa area and in Bangladesh which will cover Southasia and mideast area.

Q5: Can you costomize the equipment according to client's inquiry?

A5: Yes, we have the design team which can make customized design for clients.

Q6: Will you send engineers to install and debug the machines in client's site?

A6: Yes, we will send 3-4 engineers to client's site for installation and commissioning of the machine.

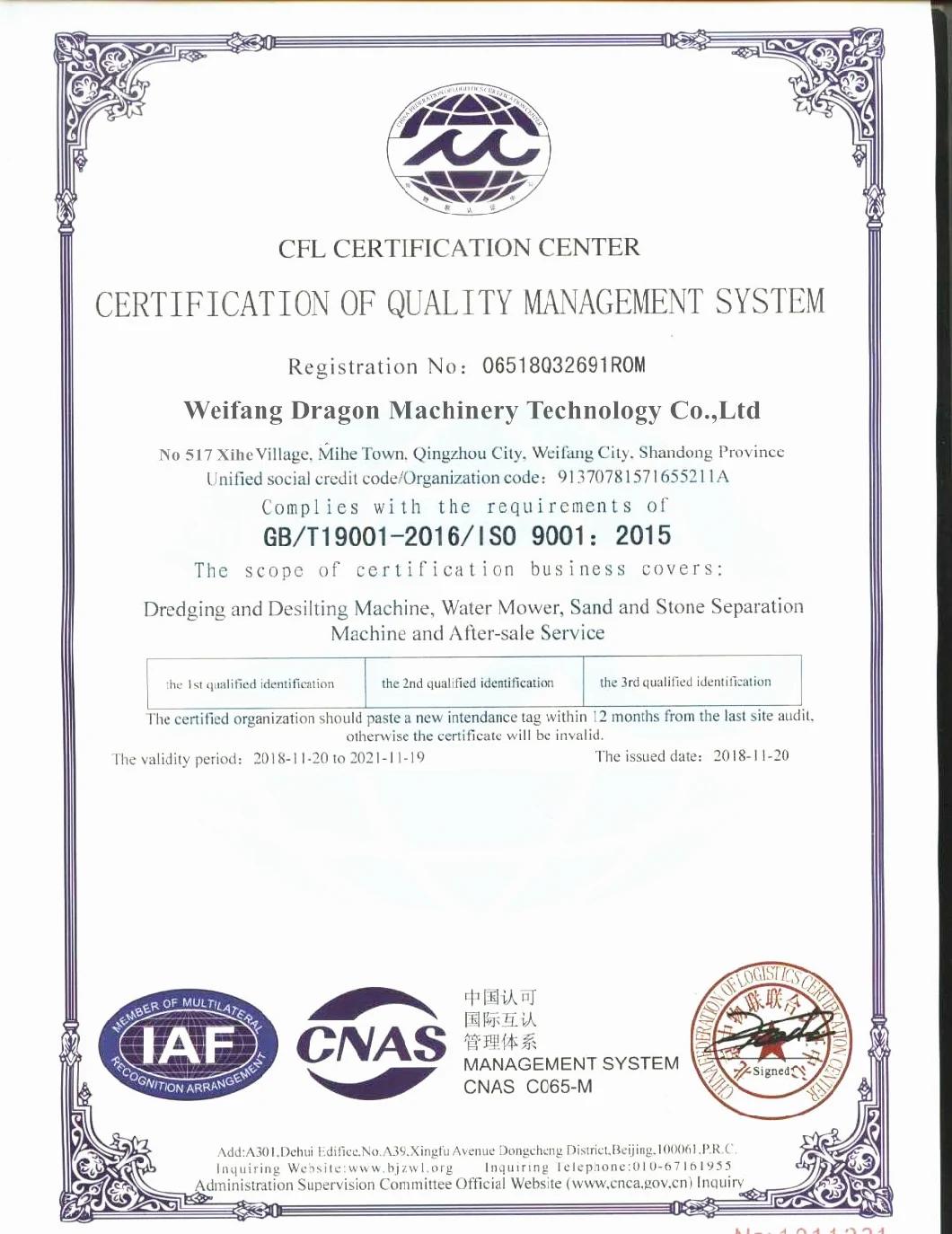

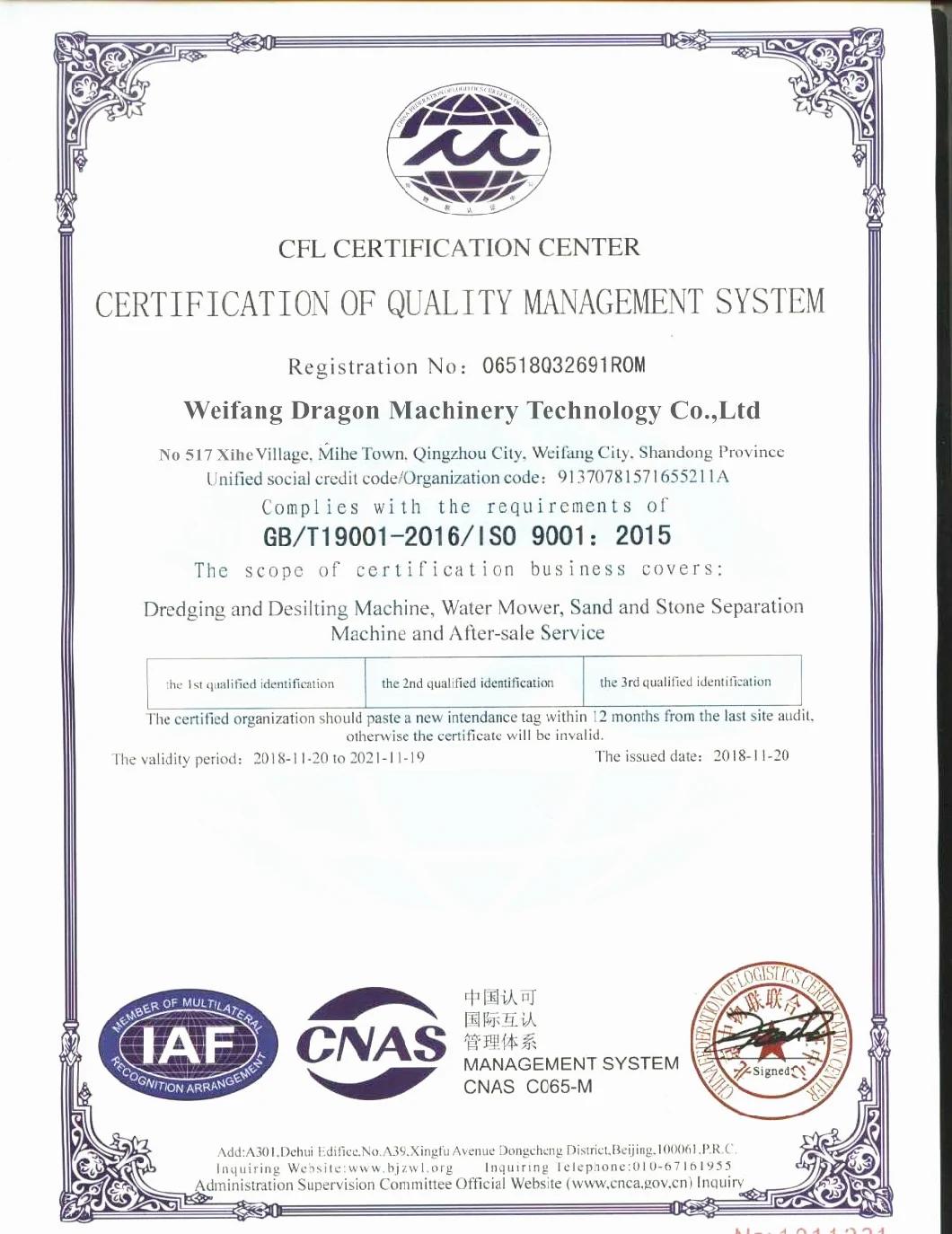

ISO 9001 Certificate

DRAGON MACHINERY IS WELCOMING THE CUSTOMERS FROM ALL OVER THE WORLD.

Front plate: 6 mm

Side plate: 6 mm

Back plate: 6 mm

Bottom: 8 mm

Brand: Cummins

Model:NT855-M

Power: 300 hp

Cooling: water

Brand: Hangzhou Advance

Model: 300

Rated Input Power: 500 kw

Diameter:300 mm

Towing Capacity: 200 Kn

Position: end of the boat

Diameter: 150 mm

Height: 350 mm

Type: A Frame Crane

Winch Capacity: 4 tons

Pilot chair: 1 set, adjustable

Magnetic compass: 1 set

Fan: 1 set

Composition: helm, hydraulic cylinders, hydraulic valves, angle gauge, pull rod.

Diameter: 900 mm

Material: copper alloy

Driving through horizontal shaft

Manufacturing Ability

Our factory is equipped with all kinds necessary manufacturing facility, including CNC cutting machine, welding robot, digital controlled lathes, machining center, milling machine, grinding machine, punching machine, and surface handling line. With all these facility, we can complete all the kinds of machining work, plate welding, finishing and painting.

After-sale Service

DRAGON customers rely on the unrivalled level of commitment that is offered to them through dedicated and comprehensive life-cycle support services. These help to maximise the equipment's availability and the return on investment, and therefore reduces the total cost of ownership. The cycle can be entered at any of its integrated stages.

DRAGON supplies high-quality and up-to-date training services for the site operation people to ensure that crews operate the dredger in a highly skilled and efficient manner to achieve optimum levels of productivity. DRAGON life-cycle support also allows operators to maintain the durability and reliability of their systems through a range of specialist services.

DRAGON team wants to be prepared for every eventuality and provide limitless logistical support to its customers.This includes attention to system availability with the immediate supply of spare parts and repair of components.With this approach, the complete DRAGON global network of qualified service technicians,sourcing officers and local service offices is available to all customers.

Customer Feedback

Customer Feedback

Why You Choose Dragon Dredger

1. Advanced Design

2. Advanced Equipment and Quality

3. Creative Design and Layout

4. Considerate Service and Training

5. Competitive Price

6. Extended Warranty

7. Performance Guarantee

8. Bring Other Cooperation Opportunities

Other Products

Dragon products scope covers all kinds of dredger, aquqtic weed harvester, amphibious excavator, workboat, backhoe barge, jack-up platform.

FAQ

Q1: Do you have your own factory?

:A1: Yes, our parent company is Weifang Dragon Machinery Technology Co.,Ltd., it is specialized in manufacturing dredgers and amphibious excavators and other machineries.

Q2: Can we visit your factory?

A2: Sure, we sincerely welcome you to visit and check our factory, we would show you around of our workshop.

Q3: Do you also supply the accessories of dredgers?

A3: Yes, we have cooperated companies to supply you the accessories and other spare parts.

Q4: Do you have aftersale service center overseas?

A4: Yes, we have aftersale service center in Nigeria which will cover Africa area and in Bangladesh which will cover Southasia and mideast area.

Q5: Can you costomize the equipment according to client's inquiry?

A5: Yes, we have the design team which can make customized design for clients.

Q6: Will you send engineers to install and debug the machines in client's site?

A6: Yes, we will send 3-4 engineers to client's site for installation and commissioning of the machine.

ISO 9001 Certificate

DRAGON MACHINERY IS WELCOMING THE CUSTOMERS FROM ALL OVER THE WORLD.