Dolomite Grinding Ball Mill

Henan Zhengzhou Mining Machinery Co., Ltd.- Type:Grinding Equipment

- Motor Type:AC Motor

- Motor Power:18.5KW

- Rotationl Speed:20-22r,min

- Application:Railway

- Materials:Ore

Base Info

- Model NO.:Various Model

- Condition:New

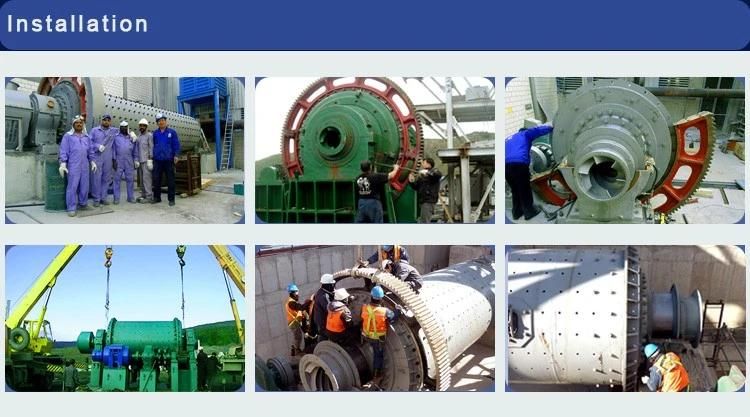

- Installation:Under Our Engineeer′s Guide

- Certificate:ISO9001, ISO14000, CE

- Color:as Your Request

- After Sale Service:for The Whole Using Life

- Model Selected:We Offer

- Design:by Our Excellent Engineers

- Warranty:1 Year

- Spare Parts:Supply for The Whole Year Freely

- Experiences:More Than 50 Years

- Testing:We Offer

- Transport Package:Export Standard Package

- Specification:various

- Trademark:ZK

- Origin:Zhengzhou, Henan, China

- HS Code:8417

- Production Capacity:100 Set,Sets Per Year

Description

Basic Info.

Model NO. Various Model Condition New Installation Under Our Engineeer′s Guide Certificate ISO9001, ISO14000, CE Color as Your Request After Sale Service for The Whole Using Life Model Selected We Offer Design by Our Excellent Engineers Warranty 1 Year Spare Parts Supply for The Whole Year Freely Experiences More Than 50 Years Testing We Offer Transport Package Export Standard Package Specification various Trademark ZK Origin Zhengzhou, Henan, China HS Code 8417 Production Capacity 100 Set/Sets Per YearProduct Description

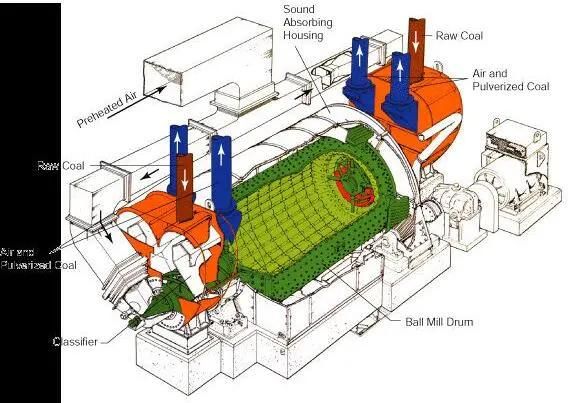

Dolomite Grinding Ball MillDolomite Grinding Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground. The rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the mill. The larger the diameter, the slower the rotation. If the peripheral speed of the mill is too great, it begins to act like a centrifuge and the balls do not fall back, but stay on the perimeter of the mill. The point where the mill becomes a centrifuge is called the "Critical Speed", and ball mills usually operate at 65% to 75% of the critical speed.

Dolomite Grinding Ball Mill Application:

Are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced. Various classifiers, such as screens, spiral classifiers, cyclones and air classifiers are used for classifying the discharge from ball mills. Ball mill is an efficient tool for grinding many materials into fine powder. The ball mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in building material, chemical industry, etc. There are two ways of grinding: The dry process and the wet process. It can be divided into tabular type and flowing type according to different forms of discharging material.

Dolomite Grinding Ball Mill Features:

1) Is an efficient tool for grinding many materials into fine powder.

2) The Dolomite Grinding Ball Mill is used to grind many kinds of mine and other materials, or to select the mine

3) Dolomite Grinding Ball Mill is widely used in building material, and chemical industry.

4) There are two ways of grinding: The dry way and the wet way.

5) Dolomite Grinding Ball Mill can be divided into tabular type and flowing type according to differentexpelling mine

6) To use the ball mill, the material to be ground is loaded into the neoprene barrel that contains grinding media.

7) As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

8) The longer the ball mill runs, the finer the powder will be.

9) Ultimate particle size depends entirely on how hard the material you're grinding is, and the time how long the ball mill runs.

10) Our Dolomite Grinding Ball Mill have been used to grind glass, powder food products, create custom varnishes, make ceramic glaze, powder various chemicals.

11) Complet ely enclosed welded design in high-grade steel.

- Direct drive via bearing journal with top-mounted gearbox.

Motor connected to gearbox via a V-belt drive.

- Product discharge via slots located around the periphery of the drum.

Dolomite Grinding Ball Mill Working Principle:

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

| Model | Speed of bucket (r/min) | Weight of ball | Size of feed opening(mm) | size of outputting feed (mm) | Production (t/h) | Power (kw) | Weight (T) |

| 900× 1800 | 38 | 1.5 | ≤ 20 | 0.075-0.89 | 0.65-2 | 18.5 | 3.6 |

| 900× 3000 | 38 | 2.7 | ≤ 20 | 0.075-0.89 | 1.1-3.5 | 22 | 4.6 |

| 1200× 2400 | 32 | 3.8 | ≤ 25 | 0 075-0.6 | 1.5-4.8 | 45 | 12.5 |

| 1200× 3000 | 32 | 5 | ≤ 25 | 0.075-0.4 | 1.6-5 | 45 | 12.8 |

| 1200× 4500 | 32 | 7 | ≤ 25 | 0.075-0.4 | 1.6-5.8 | 55 | 13.8 |

| 1500× 3000 | 27 | 8 | ≤ 25 | 0.075-0.4 | 2-5 | 90 | 17 |

| 1500× 4500 | 27 | 14 | ≤ 25 | 0.075-0.4 | 3-6 | 110 | 21 |

| 1500× 5700 | 27 | 15 | ≤ 25 | 0.075-0.4 | 3.5-6 | 132 | 24.7 |

| 1830× 3000 | 24 | 11 | ≤ 25 | 0.075-0.4 | 4-10 | 180 | 28 |

| 1830× 6400 | 24 | 23 | ≤ 25 | 0.075-0.4 | 6.5-15 | 210 | 34 |

| 1830× 7000 | 24 | 25 | ≤ 25 | 0.075-0.4 | 7.5-17 | 245 | 36 |

| 2200× 5500 | 21 | 30 | ≤ 25 | 0.075-0.4 | 10-22 | 370 | 48.5 |

| 2200× 6500 | 21 | 30 | ≤ 25 | 0.075-0.4 | 14-26 | 280 | 52.8 |

| 2200× 7500 | 21 | 33 | ≤ 25 | 0.075-0.4 | 16-29 | 475 | 56 |

Training & Service

Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design and manufacturer equipment,

according to your special demand.

Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment, training operators

and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warrantee to make sure your machine runs consistently. We always keep certain inventory?level of spare parts, which means the replacements can be shipped to you right away.

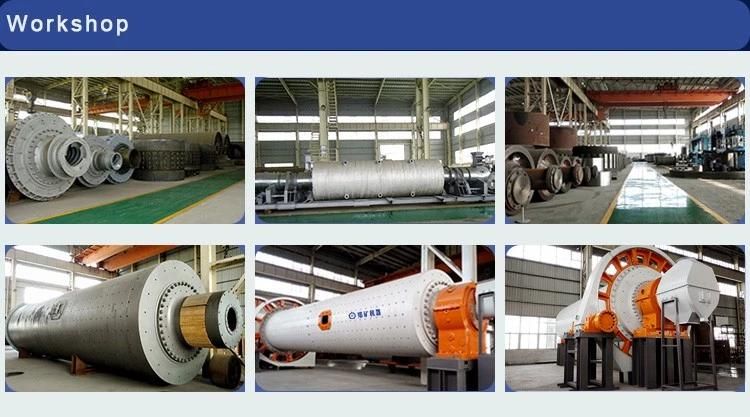

Welcome to visit our company and workshop, we sincerely look forward to cooperating with

you. We will provide you with the most suitable products with the reasonable price.