Vertical Wet High Intensity Magnetic Separator Whims for Red Ore/ Chrome/ Manganese/ ...

SLon Magnetic Separator Co., Ltd.- Type:Magnetic Separator

- Voltage:Customized

- Weight:>10T

- Material:Stainless Steel

- Material Feature:Conductivity

- Certification:CE, ISO9001:2015

Base Info

- Model NO.:SLon-2500

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Multi Color

- Customized:Customized

- Condition:New

- After-sales Service:Lifetime

- Capacity:100~150t,H

- Ore-Feeding Size:-1.3mm

- Ore-Feeding Concentration:10%~40%

- Water Consumption:160~220m3,H

- Magnetic Field Strength:0.6-1.8t

- Installation:Site Installation

- After-Sale Service:Lifetime

- Transport Package:Seaworthy Packing

- Specification:SLon-2500

- Trademark:SLon

- Origin:China

- HS Code:8474100000

- Production Capacity:20sets,Month

Description

SLon WHIMS for Non-metallic MineralsParameters SLon-2500 SLon-2500 SLon-2500 SLon-2500 SLon-2500 Ring diameter /mm 2500 2500 2500 2500 2500 Ring speed /(r/min) 2.5~3.5 2.5~3.5 2.5~3.5 2.5~3 2.5~3.5 Feed size /(mm),(-74μm%) -1.3(30~100) -1.3(30~100) -1.3(30~100) -1.3(30~100) -1.3(30~100) Feed density/% 10~40 10~40 10~40 10~40 10~40 Slurry throughput /(m3/h) 200~400 200~400 200~400 200~400 150~300 Ore throughput /(t/h) 50~150 50~80 50~80 50~80 30~50 Background field /T 0.6 1/1.1 1.3 1.5 1.8 Rated current /A 1250 1200 1400 1550 2050 Rated voltage /V 33 52 49 65 73 Rated power /kW 41 62 69 100 149 Ring motor /kW 5.5 11 11 11 11 Water pressure /MPa 0.2~0.4 0.2~0.4 0.2~0.4 0.2~0.4 0.2~0.4 Flushing water consumption/(m3/h) 160~220 160~220 160~220 160~220 80~100 Cooling water consumption /(m3/h) 3~4 4~5 6~7 7~8 7~8 Max part weight /t 15 16 17 21 21 Dimensions (L*W*H) /mm 3490×3800×5050 3230×4350×5200 3350×4950×5550 3350×5220×5820 3420×4920×5160 Parameters SLon-2500 SLon-2500 SLon-2500 SLon-2500 SLon-2500 Ring diameter /mm 2500 2500 2500 2500 2500 Ring speed /(r/min) 2.5~3.5 2.5~3.5 2.5~3.5 2.5~3 2.5~3.5 Feed size /(mm),(-74μm%) -1.3(30~100) -1.3(30~100) -1.3(30~100) -1.3(30~100) -1.3(30~100) Feed density /% 10~40 10~40 10~40 10~40 10~40 Slurry throughput /(m3/h) 200~400 200~400 200~400 200~400 150~300 Ore throughput /(t/h) 100~150 100~150 100~150 100~150 65~100 Background field /T 0.6 1/1.1 1.3 1.5 1.8 Rated current /A 1250 1200 1400 1550 2050 Rated voltage /V 33 52 49 65 73 Rated power /kW 41 62 69 100 149 Ring motor /kW 5.5 11 11 11 11 Pulsating motor /kW 11 11 11 11 7.5 Pulsating stroke /mm 0~26 0~26 0~26 0~26 0~26 Pulsating speed /(per/min) 0~300 0~300 0~300 0~300 0~300 Water pressure /MPa 0.2~0.4 0.2~0.4 0.2~0.4 0.2~0.4 0.2~0.4 Flushing water consumption /(m3/h) 160~220 160~220 160~220 160~220 80~100 Cooling water consumption /(m3/h) 3~4 4~5 6~7 7~8 7~8 Max part weight /t 15 16 17 21 21 Dimensions (L*W*H) /mm 5700×3800×5050 5600×4350×5200 5600×4950×5550 5640×5220×5820 4820×4920×5160

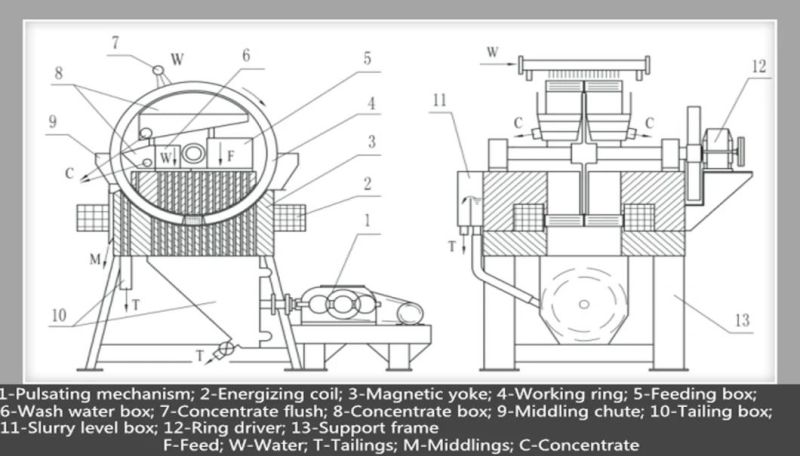

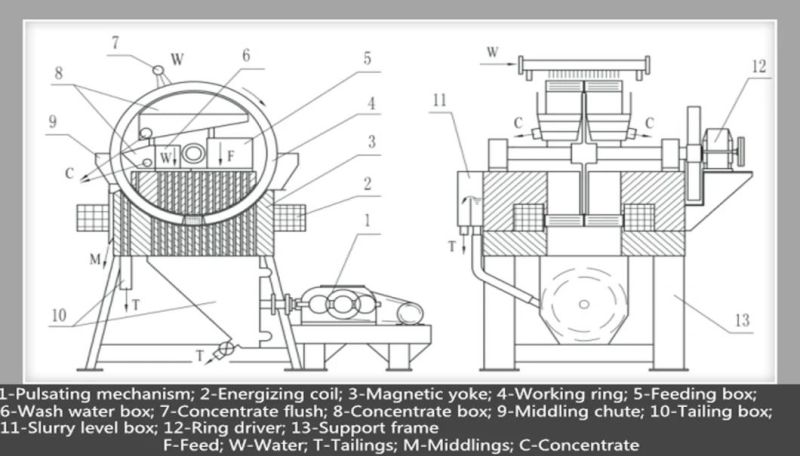

Working Principle:

SLon VPHGMS mainly consists of the energizing coil, magnetic yoke, separating ring, feed and product boxes as shown in Figure. Expanded nets or round bars made of magnetic conductive stainless steel are used as matrix. While a direct electric current follows through the energizing coil, a magnetic field is built up in the separating zone. The ring with matrix rotates clockwise. Slurry from the feed box enters into matrix piles located in the separating zone. Magnetic particles are attracted from slurry onto the surface of the matrix, brought to the top of the ring where magnetic field is negligible, then flushed out into the concentrate box. Non-magnetic particles pass through the matrix and enter the tailing box under the combined force action of slurry pulsation, gravity, and hydrodynamic drag.

As the ring rotates vertically, flushing direction of mags is opposite to that of feed relative to each matrix pile, coarse particles can be flushed out without having to pass through the entire depth of matrix pile. The pulsating mechanism drives slurry in the separating zone up and down, keeping the particles the matrix pile in loose state, so that magnetic particle can be more easily captured by the matrix and nonmagnetic particles can be more easily dragged to the tailing box through the matrix pile. Obviously, opposite flushing and pulsation help to prevent matrix clogging, and pulsating helps to purity magnetic product.

Successful Cases

Being the leader in the industry, SLon's magnetic separator equipment has been widely applied in the field of metallic and non-metallic minerals. Its tracks cover more than 20 countries and regions, including America, Canada, Brazil, Peru, Russia, Korea, India, Iran, Thailand, Philippines, Australia, Sierra Leone and so on. With market holdings of over 4000 machines, SLon has been the largest supplier of magnetic separation equipment in the industry.

Certificates&Patents

SLon always believes that technology is the root of one company. Otherwise, we would risk being an outcast of society with constant change. Therefore, in the past 30 years, SLon has been dedicated to the cutting-edge technology of magnetic separation. Up to now, SLon has been granted 22 invention patents, 39 utility model patents, 4 software copyrights and 65 intellectual property rights in total. At present, there are still 10 patents under substantive examination. It's our commission to introduce the most advanced products and take the lead in the field of electromagnetism.

Package&Delivery

SLon has engaged in export business for over 20 years. We can deal with most of unforeseen circumstances during transportation. Our packages strictly comply with international standards, which ensures that the products are in good condition when you receive them.

Our Service

SLon aims at "100% product qualification, 100% contract performance, 98% equipment operation, 100% customer satisfaction, and zero customer complaint". To achieve the goal, it has established an advanced quality management system integrating experiment, technological process advice, customized product, installation and commissioning, remote instruction, and regular visit. Whenever and Wherever the magnetic separator equipment goes wrong, its professional team will be sent to your plants as soon as possible. It's high quality and excellent service that SLon persists in.

Experiment Photos

Exhibition Photos

Exhibition Photos

Company Profile

To be fully adapted to the fast-paced world, continuous technology innovation is essential. Upon its establishment, SLon has always focused on the key technology that matters the most. It owns one of the world's best R&D teams dedicated to high intensity magnetic separation, whose staff includes 117 highly educated researchers, designers and engineers. With the unremitting efforts for years, SLon possesses a number of products and patented technology, and has successively completed many projects at the national level.

To be fully adapted to the fast-paced world, continuous technology innovation is essential. Upon its establishment, SLon has always focused on the key technology that matters the most. It owns one of the world's best R&D teams dedicated to high intensity magnetic separation, whose staff includes 117 highly educated researchers, designers and engineers. With the unremitting efforts for years, SLon possesses a number of products and patented technology, and has successively completed many projects at the national level.

Dr XiongDahe, as the founder and leader of SLon professional team, was born in July 1952. From 1982 to1988, he studied in Jiangxi Institute of Metallurgy and Central South University of Technology, majoring in mineral processing machinery. Later, he has served as deputy director of Ganzhou Nonferrous Metallurgy Research Institute, and chairman and general manager of SLon Magnetic Separator Limited. As the Inventor of Vertical Pulsating High Gradient Magnetic Separator(VPHGMS), he has never stopped the research on magnetic separation over the past 30 years. His research isn't more than just theory, and focuses on practical application, which has realized the breakthrough of vertical pulsating high gradient magnetic separation technology from theoretical research to large-scale industrial application. Besides, a series of advanced processing equipment with independent intellectual property rights, have significantly promoted the comprehensive utilization level of weak magnetic ores and non-metallic mineral resources, such as iron ore, titanium, iron oxide ore, manganese ore, tungsten, tantalum niobium and rare earth. All of this have not only made great contribution to the development of mineral processing in China, but also created remarkable economic and social benefits.

Up to now, Dr XiongDahe has put forward more than one hundred studies and papers at home and abroad. He has successively undertook over 20 national and provincial major scientific research projects, and obtained three national patents, one national award, 13 scientific and technological progress at ministerial and provincial level, and three at national level. In 2014, he has been received cordially by state leaders. Besides, XiongDahe has awarded a lot of honorary titles by the state and all levels of organizations, such as the "national excellent science and technology workers", "national May 1st labor medal", "model workers in Jiangxi province", "special nonferrous corporation model worker", "top ten outstanding youth in Jiangxi province", "national outstanding contribution expert", "enjoying special government allowances" and "jiangling elite of science and technology award".

FAQ

Q:Why do you choose SLon as your mineral consultant?

A: 1)Specialty: In the past 20 years, SLon has specialized in magnetic separation. It serves 3000+ concentrators around the world processing 30+ minerals;

2)Innovation: SLon owns one of the world's best R&D teams dedicated to cutting-edge technology;

3)One-stop service: SLon integrates experiment, technological process advice, customized product, installation and commissioning gudiance, remote instruction, and regular visit.

Q: Factory or Trading Company?

A: SLon is an intergrated set of factory and trading company established in 2001.

Q: How can I get an efficient & suitable quotation in time?

A: Before quotation, we need to ensure the specific model of machines. We have to konw the minerals, mineral features, material size, processing capacity, magnetic filed intensity and other technical parameters. If you have done mineral test before, please kindly show the reports to us. According to all of these factors, we'll introduce the most suitable machines to you and provide customized service.

Q: Can I send the mineral samples to you for testing? How much does it cost?

A: Of course. SLon owns the provincial key laboratory. Our technical engineers are all experienced in both processing technology design and mineral separation. You're always welcome to send samples for the mineral test to see the actual effects running on our machines. Most of all, it's totally free of charge.

Q: How long is the warrenty of your magnetic separators?

A: SLon provide one-year period warrenty and lifetime after-sales service.

If you are interested in our machines, please feel free to chat with us or leave the messages. We'll reply you within 24 hours. Looking forward to your inquiry.

Working Principle:

SLon VPHGMS mainly consists of the energizing coil, magnetic yoke, separating ring, feed and product boxes as shown in Figure. Expanded nets or round bars made of magnetic conductive stainless steel are used as matrix. While a direct electric current follows through the energizing coil, a magnetic field is built up in the separating zone. The ring with matrix rotates clockwise. Slurry from the feed box enters into matrix piles located in the separating zone. Magnetic particles are attracted from slurry onto the surface of the matrix, brought to the top of the ring where magnetic field is negligible, then flushed out into the concentrate box. Non-magnetic particles pass through the matrix and enter the tailing box under the combined force action of slurry pulsation, gravity, and hydrodynamic drag.

As the ring rotates vertically, flushing direction of mags is opposite to that of feed relative to each matrix pile, coarse particles can be flushed out without having to pass through the entire depth of matrix pile. The pulsating mechanism drives slurry in the separating zone up and down, keeping the particles the matrix pile in loose state, so that magnetic particle can be more easily captured by the matrix and nonmagnetic particles can be more easily dragged to the tailing box through the matrix pile. Obviously, opposite flushing and pulsation help to prevent matrix clogging, and pulsating helps to purity magnetic product.

Successful Cases

Being the leader in the industry, SLon's magnetic separator equipment has been widely applied in the field of metallic and non-metallic minerals. Its tracks cover more than 20 countries and regions, including America, Canada, Brazil, Peru, Russia, Korea, India, Iran, Thailand, Philippines, Australia, Sierra Leone and so on. With market holdings of over 4000 machines, SLon has been the largest supplier of magnetic separation equipment in the industry.

Certificates&Patents

SLon always believes that technology is the root of one company. Otherwise, we would risk being an outcast of society with constant change. Therefore, in the past 30 years, SLon has been dedicated to the cutting-edge technology of magnetic separation. Up to now, SLon has been granted 22 invention patents, 39 utility model patents, 4 software copyrights and 65 intellectual property rights in total. At present, there are still 10 patents under substantive examination. It's our commission to introduce the most advanced products and take the lead in the field of electromagnetism.

Package&Delivery

SLon has engaged in export business for over 20 years. We can deal with most of unforeseen circumstances during transportation. Our packages strictly comply with international standards, which ensures that the products are in good condition when you receive them.

Our Service

SLon aims at "100% product qualification, 100% contract performance, 98% equipment operation, 100% customer satisfaction, and zero customer complaint". To achieve the goal, it has established an advanced quality management system integrating experiment, technological process advice, customized product, installation and commissioning, remote instruction, and regular visit. Whenever and Wherever the magnetic separator equipment goes wrong, its professional team will be sent to your plants as soon as possible. It's high quality and excellent service that SLon persists in.

Experiment Photos

Exhibition Photos

Exhibition Photos

Company Profile

To be fully adapted to the fast-paced world, continuous technology innovation is essential. Upon its establishment, SLon has always focused on the key technology that matters the most. It owns one of the world's best R&D teams dedicated to high intensity magnetic separation, whose staff includes 117 highly educated researchers, designers and engineers. With the unremitting efforts for years, SLon possesses a number of products and patented technology, and has successively completed many projects at the national level.

To be fully adapted to the fast-paced world, continuous technology innovation is essential. Upon its establishment, SLon has always focused on the key technology that matters the most. It owns one of the world's best R&D teams dedicated to high intensity magnetic separation, whose staff includes 117 highly educated researchers, designers and engineers. With the unremitting efforts for years, SLon possesses a number of products and patented technology, and has successively completed many projects at the national level.Dr XiongDahe, as the founder and leader of SLon professional team, was born in July 1952. From 1982 to1988, he studied in Jiangxi Institute of Metallurgy and Central South University of Technology, majoring in mineral processing machinery. Later, he has served as deputy director of Ganzhou Nonferrous Metallurgy Research Institute, and chairman and general manager of SLon Magnetic Separator Limited. As the Inventor of Vertical Pulsating High Gradient Magnetic Separator(VPHGMS), he has never stopped the research on magnetic separation over the past 30 years. His research isn't more than just theory, and focuses on practical application, which has realized the breakthrough of vertical pulsating high gradient magnetic separation technology from theoretical research to large-scale industrial application. Besides, a series of advanced processing equipment with independent intellectual property rights, have significantly promoted the comprehensive utilization level of weak magnetic ores and non-metallic mineral resources, such as iron ore, titanium, iron oxide ore, manganese ore, tungsten, tantalum niobium and rare earth. All of this have not only made great contribution to the development of mineral processing in China, but also created remarkable economic and social benefits.

Up to now, Dr XiongDahe has put forward more than one hundred studies and papers at home and abroad. He has successively undertook over 20 national and provincial major scientific research projects, and obtained three national patents, one national award, 13 scientific and technological progress at ministerial and provincial level, and three at national level. In 2014, he has been received cordially by state leaders. Besides, XiongDahe has awarded a lot of honorary titles by the state and all levels of organizations, such as the "national excellent science and technology workers", "national May 1st labor medal", "model workers in Jiangxi province", "special nonferrous corporation model worker", "top ten outstanding youth in Jiangxi province", "national outstanding contribution expert", "enjoying special government allowances" and "jiangling elite of science and technology award".

FAQ

Q:Why do you choose SLon as your mineral consultant?

A: 1)Specialty: In the past 20 years, SLon has specialized in magnetic separation. It serves 3000+ concentrators around the world processing 30+ minerals;

2)Innovation: SLon owns one of the world's best R&D teams dedicated to cutting-edge technology;

3)One-stop service: SLon integrates experiment, technological process advice, customized product, installation and commissioning gudiance, remote instruction, and regular visit.

Q: Factory or Trading Company?

A: SLon is an intergrated set of factory and trading company established in 2001.

Q: How can I get an efficient & suitable quotation in time?

A: Before quotation, we need to ensure the specific model of machines. We have to konw the minerals, mineral features, material size, processing capacity, magnetic filed intensity and other technical parameters. If you have done mineral test before, please kindly show the reports to us. According to all of these factors, we'll introduce the most suitable machines to you and provide customized service.

Q: Can I send the mineral samples to you for testing? How much does it cost?

A: Of course. SLon owns the provincial key laboratory. Our technical engineers are all experienced in both processing technology design and mineral separation. You're always welcome to send samples for the mineral test to see the actual effects running on our machines. Most of all, it's totally free of charge.

Q: How long is the warrenty of your magnetic separators?

A: SLon provide one-year period warrenty and lifetime after-sales service.

If you are interested in our machines, please feel free to chat with us or leave the messages. We'll reply you within 24 hours. Looking forward to your inquiry.