Large Capacity Grain Bucket Elevator Price for Rice Mill

Henan Excellent Machinery Co., Ltd.- Type:Vertical Conveyor

- Structure:Fully Sealed Structure

- Material:Carbon Steel,Stainless Steel

- Material Feature:Sturdy and Durable

- Certification:ISO9001:2008, CE

- Energy Saving:Energy Saving

Base Info

- Model NO.:TDG

- Warranty:12 Months After The Completion of Commissioning

- Color:According to Customer Requirements

- Customized:Customized

- Condition:New

- After-sales Service:Online Support, Field Service

- Handling Capacity:10-1841 M3,H

- Bucket Width:200,250,315,400,500,630,800,1000,1250,1600mm

- Bucket Speed:0.5,0.8,1.0,1.2,1.34,1.5,1.68,1.86 M,S

- Bucket Volume:1.9-502 L

- Max Lifting Height:80 M

- Bucket Space:200-820 mm

- Filling Factor:75%

- Traction Components:Conveyor Belt , Plate Chain

- Application:Cement,Metallurgy,Grain,Food,Chemical Industry

- Max Material Temperature:250ºC

- Loading Pattern:Extract , Flow

- Discharge Method:Gravity , Centrifugal+Gravity Hybrid

- Motor Brand:ABB,Siemens,Weg,Chinese Brand

- Reducer Brand:Sew,Flender,Chinese Brand

- Take-up Type:Gravity+Spring , Gravity Type

- Transport Package:Steel Frame + Wooden Box

- Specification:100-1600

- Trademark:EXCT

- Origin:Henan Province, China

- HS Code:8428320000

- Production Capacity:200 Sets,Year

Description

Product Details: Feature: Company Profile:

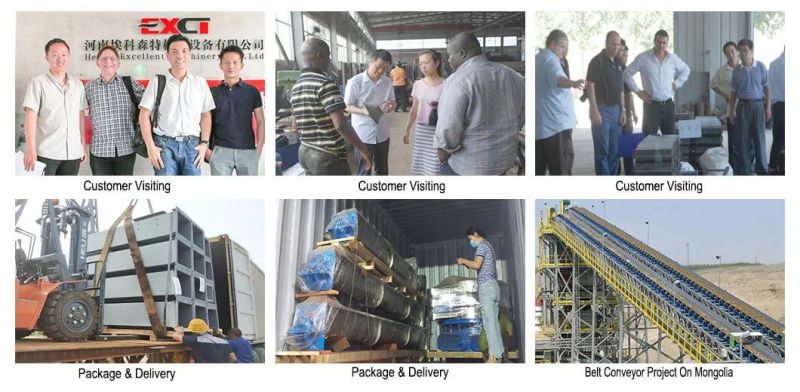

Henan Excellent machinery Co., LTD is a professional bulk material handling equipment manufacturer providing comprehensive solutions to customers worldwide. Our Factory is located in Xinxiang City ( China's city ) and covers an area of about 39,600 square meters. It owns 15,800 square meters of standard heavy-duty industrial plants and more than 140 sets of advanced machining processing, riveting and assembling equipment. EXCT's main products include Mineral Sizers, Vibrating Screen, Belt Conveyor, Bucket Elevator, Apron Feeder, Trough Chain Conveyor, Screw Conveyor, Conveyor Idler and etc. Our product is widely used in mine, port, coal, electric power, metallurgy, building materials, chemicals, food and other fields.

EXCT has a comprehensive international trade service system from marketing promotion to negotiation and cooperation, from domestic one-stop consultation services to localized services in dozens of countries and regions abroad. By the end of 2020, EXCT has delivered reliable products and services to over 2000 customers in 60 countries and regions.

Qualification:

Manufacturing Facilities:

Henan Excellent Machinery Co., Ltd has more than 30 years of production experience and has maintained long-term cooperation with many domestic universities and design institutes, committed to the world's advanced bulk material processing technology research so that our products are in the industry-leading level. EXCT not only owns more than 140 sets of high-end manufacturing equipment such as laser cutting machine, CNC turret punch, automatic production line of the idler, welding robot, CNC planer, and horizontal milling but also has a large number of experienced technical workers to ensure the reliability of product quality.

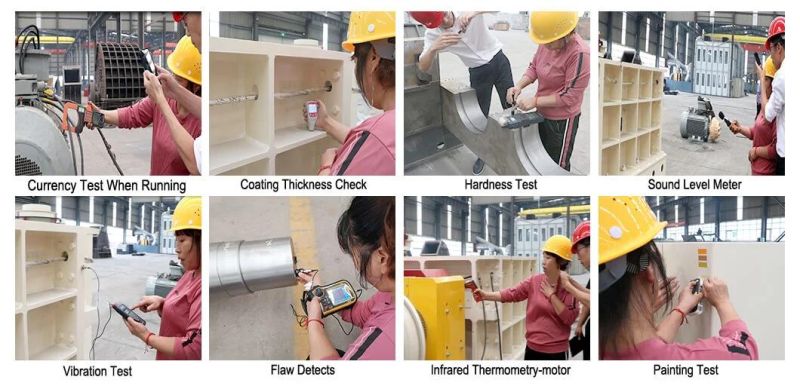

Strict Quality Control:

Complete After-sales service:

1.Free repair and replacement

Within the warranty period, if the equipment malfunctions in the correct use, we will guarantee free repair and replacement of spare parts.

2.Supply spare parts

During the normal service life of the equipment, we will provide spare parts with reliable quality and reasonable price.

3.Remote diagnosis and on-site service

When the equipment malfunctions, our after-sales service engineers can diagnose the equipment by video and guide the on-site operators to troubleshoot the equipment. If the equipment fault still cannot be removed, We will arrange professional after-sales service engineers to remove the fault on site.

Oversea:

EXCT's quality control procedures specify different inspection requirements at different stages. After the production starts, engineers in the quality control department will test and mark the products at different control nodes according to their own detection scope, so as to realize the whole process of quality control tracking.