Wet High Intensity Magnetic Mineral Refining Separator Magnetic Selection Gtlh-2000

Weifang Guote Mining Equipment Co., Ltd.- Type:Magnetic Separator

- Voltage:380V

- Weight:1-50ton

- Material:Stainless Steel

- Material Feature:Sturdy Material

- Certification:ISO9001:2008, ISO9001:2000, CE

Base Info

- Model NO.:GTLH

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:According Requirements

- Customized:Customized

- Condition:New

- Name:Magnetic Separator

- Background Magnetic Field:1.4,1.8t

- Water Consumption:0.75-300m3,H

- Slurry Density:10-40%

- Item:Beneficiation Plant

- Magnetic Field Intensity:1500-2000GS

- Material Size:0-6mm

- Ring Diameter:400-2500mm

- Installation:Technical Guidance

- Date of Delivery:60 Days

- Capacity:1-220 Ton Per Hour

- Power:1.5-75kw

- Advantage:Large Capacity

- Features:Electromagnetic Separator

- Supply Ability:602 Set,Sets Per Year

- Transport Package:Container or According Requirements

- Specification:Magnetic Separator

- Trademark:GUOTE

- Origin:China

- HS Code:8474100000

- Production Capacity:8698set,Month

Description

Basic Info.

Model NO. GTLH Energy Saving Energy Saving Warranty 1 Year Color According Requirements Customized Customized Condition New Name Magnetic Separator Background Magnetic Field 1.4/1.8t Water Consumption 0.75-300m3/H Slurry Density 10-40% Item Beneficiation Plant Magnetic Field Intensity 1500-2000GS Material Size 0-6mm Ring Diameter 400-2500mm Installation Technical Guidance Date of Delivery 60 Days Capacity 1-220 Ton Per Hour Power 1.5-75kw Advantage Large Capacity Features Electromagnetic Separator Supply Ability 602 Set/Sets Per Year Transport Package Container or According Requirements Specification Magnetic Separator Trademark GUOTE Origin China HS Code 8474100000 Production Capacity 8698set/MonthProduct Description

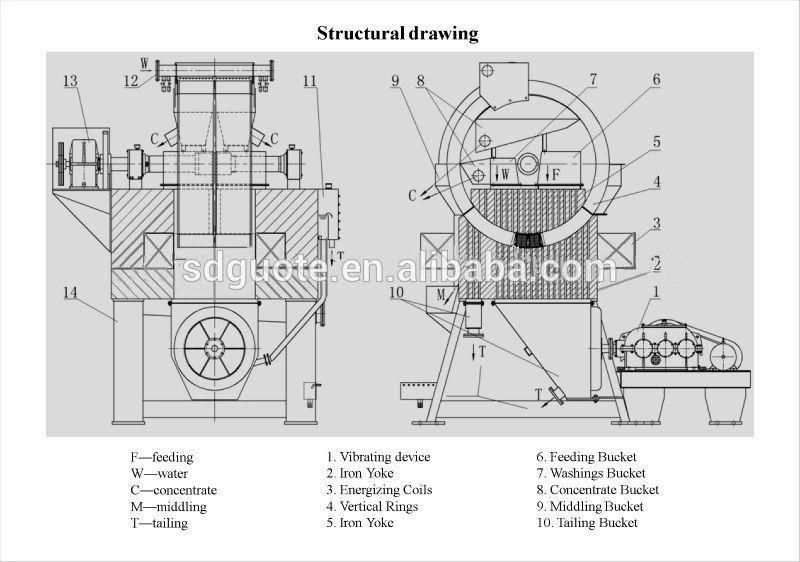

GTLH Vertical Ring High Gradient Magnetic Separator for Non-metallic mineralsA summary:

This product is applicable to 1.2 mm (- 200Mesh 30-100%) of fine non-metallic mineral, such as quartz, feldspar, nepheline ore, kaolin, iron removal purification. Can also be used for red iron ore (hematite, limonite and siderite, etc.), manganese ore, ilmenite, black tungsten, a variety of weak magnetic ore wet separation and black and white tungsten separation, black tungsten and tin separation.

GTLH Series high gradient magnetic separator is a new product developed independently by GUOTE. It combines the characteristics of international advanced high intensity magnetic separators, which is so far the high intensity magnetic separator of best performance and most advanced technology. This product utilizes vertical ring rotation, pulsating beneficiation and high frequency vibrator, and it has no magnetic medium jam problem in flat ring high intensity magnetic separator and flat ring high gradient magnetic separator.

It has the advantages of large beneficiation ratio, high security and convenient operation etc. This product realizes both high beneficiation ratio and high recycle ratio in separating weak magnetic minerals.

Frist ,Features of GTLH series Vertical Ring High Gradient Magnetic Separator:

1.Its separation ring is designed to be vertical,fine ore is discharged by reverse flow and also with separation pulse device .

2.Powerful magnetic force, reliable and Series GTLH Vertical High Gradient Magnetic Separator science performance

3. Simple installation and easy to maintain

4.Collecting and discharging continuously Long-term trouble-free operation

Second ,Application field of GTLH series Vertical Ring High Gradient Magnetic Separator:

1. Updating Ferrous Metals: Martite, Hematite, Siderite, Chromite, Ilmenite, Manganese, Etc.

2. Separating Non-Ferrous Metals: Wolframite and Quartz, Pyrrhotite and Cassiterite, Wolframite and Cassiterite, Limonite Purifying, Scheelite, Wolframite and Garnet, Etc.

3. Recovering Rare Earth: Tantalum and Niobium, Lepidomelane, Monazite, Etc.

4. Brightening Non Metals: Quartz, Feldspar And Kaolin for Ceramics, Sillimanite, Cassiterite, Andalusite, Kyanite for Refractory, and Separating Impurities From Hornblende, Mica, Tourmaline, Garnet, Etc.

Third, Technical parameter of GTLH series Vertical Ring High Gradient Magnetic Separator:

| Model | Ring Diameter (mm) | Feed Particles Size(mm) | Slurry density (%) | Handling Capacity (t/h) | Slurry Throughput (m3/h) | Rated Background Magnetic Field(T) | Energizing Power (KW) | Ring motor Power (KW) | Vibration Motor Power (KW) | Water Supply Pressure (MPa) | Water Consumption (m3/h) | Main Frame Weight (t) | Overall Dimension (mm) |

| GTLH-500 | 500 | -1 | 10~40 | 0.1-0.3 | 0.25-0.5 | 1.1 | 16 | 0.37 | 0.37 | 0.1-0.2 | 0.65-1.4 | 1.5 | 1800*1400*1320 |

| GTLH-750 | 750 | -1 | 10~40 | 0.1-0.5 | 5-10 | 1.1 | 21 | 0.55 | 1.5 | 0.1-0.2 | 1.4-2.5 | 3 | 2000*1360*1680 |

| GTLH-1000 | 1000 | -1.2 | 10~40 | 3.5-7.5 | 12.5-20 | 1.1 | 30.8 | 1.5 | 2.2 | 0.2-0.4 | 8-12 | 6 | 2700*2000*2400 |

| GTLH-1250 | 1250 | -1.2 | 10~40 | 10-20 | 20-50 | 1.1 | 37.8 | 2.2 | 3 | 0.2-0.4 | 20-30 | 14 | 3200*2340*2700 |

| GTLH-1500 | 1500 | -1.2 | 10~40 | 20-30 | 50-100 | 1.1 | 46.2 | 4 | 3 | 0.2-0.4 | 20-30 | 24 | 3600*2900*3200 |

| GTLH-1750 | 1750 | -1.2 | 10~40 | 30-50 | 75-150 | 1.1 | 65.3 | 4 | 4 | 0.2-0.5 | 30-50 | 35 | 3900*3300*3800 |

| GTLH-2000 | 2000 | -1.2 | 10~40 | 50-80 | 100-200 | 1.1 | 78.3 | 5.5 | 7.5 | 0.2-0.4 | 50-100 | 50 | 4200*3550*4200 |

| GTLH-2500 | 2500 | -1.2 | 10~40 | 80-150 | 200-400 | 1.1 | 96.3 | 11 | 11 | 0.2-0.4 | 100-150 | 105 | 5800*5000*5400 |

| GTLH-3000 | 3000 | -1.2 | 10~40 | 150-250 | 350-650 | 1.1 | 103.6 | 18.5 | 18.5 | 0.2-0.4 | 150-250 | 150 | 7600*6500*7200 |

Fourth,Technical features:

1. Vertical Ring Rotation & Pulsating Beneficiation

2. High Frequency Vibration Mechanism

3. Wide Range of Feed Particle Size

4. Multi-Gradient Matrixes & Liquid Level Control System.

These technologies improve the grade of magnetic concentrate and recovery.

5. Frequency Conversion Step-less Adjustment for Rotary Speed & Vibrating Frequency.

6. No Stepper Phenomenon of Rotary Rings

Company Information

Certification

Our customers :

FAQ

1.What main products do you supply?

- Ball mill with air classifying production line

- Quartz Feldspar (galss sand) wet process production line

- High pure sand making machine

- GF Air classifier

- Dust collector

- High gradient vertical ring magnetic separator

- Plate type magnetic separator (Up to 15000GS)

- Drum/Roller type permanent magnetic separator

- GSC series hindered settling machine density separator

- EPC service for whole equipments

2 . Are you a trading company or factory?

- We are professional manufacturer of non-metallic minerals separation equipment , EPC service supplier for engineering/Procurement/Construction ,You are welcome to visit our factory and discuss for further business.

3. Delivery date for my order?

- 5 to 15 days for generally single equipment

- 30 to 45 days for whole production line.

4 .How about your payment methods?

- Generally 30% in advance for down payment and balance paid before shipment

- Accept T/T, Western Union, Cash, L/C at sight. etc.

- Suggest Alibaba as third party for business.

5. How do you handle the shipment for my order?and Packing?

- Its the most economic way to receive your order. Totally seaworthy packing and pallet for delivery.

- Small parts are wooden case packing and inner film proctection

- Big parts are containers for delivery and steel wire/wooden material for stablly fastened and plastic film for protection.

- We could accept customized packing terms.

6. What is your company warranty policy?

- 12 months warranty since machinery in working process or 18 months since the equipment get into shipment.

- Whole life for offering spare parts and technical problems shooting and update.

7. Do you offer any replacement for my order?

- Yes, we will offer you the replacements based on the model and quantity you are going to order.

8. How can I contact to you?

- contact :We could make whole production line or single equipment following different clients requirements.

- For whole process as below:

Firstly, Please offer detailed technical drawing in CAD or requirements. Secondly, we will offer different technical proposals follwing offered drawings or requirements for clients. Thridly make decision for which proposal.At last manufacture whole equirements following techncial proposal and holding test in warehouse. Finally finished equipment/prodcution line offered as turn-key project.

For details, please contact :