High Efficient Low Energy Crashing/Crushing Plant with 50-800tph

Shanghai Zenith Mineral Co., Ltd.- Type:Jaw Crusher

- Motor Type:AC Motor

- Motor Power:110kw

- Application:Mine

- Materials:Ore

- Outlet Size:Various According to Different Model

Base Info

- Model NO.:PEW250x1200, PEW400x600, PEW760, PEW860

- Inlet Size:Various According to Different Model

- Condition:New

- Spare Parts Supply:for Whole Year

- After-Sale Service:for Whole Using Year

- Test&Installation:Engineer Assigned

- Export Markets:Global

- Transport Package:Container, Nude Packs, in Bulk

- Specification:ISO9001: 2000

- Trademark:Zenith

- Origin:China

- HS Code:8474209000

- Production Capacity:1000 Set,Year

Description

Basic Info.

Model NO. PEW250x1200, PEW400x600, PEW760, PEW860 Inlet Size Various According to Different Model Condition New Spare Parts Supply for Whole Year After-Sale Service for Whole Using Year Test&Installation Engineer Assigned Export Markets Global Transport Package Container, Nude Packs, in Bulk Specification ISO9001: 2000 Trademark Zenith Origin China HS Code 8474209000 Production Capacity 1000 Set/YearProduct Description

High Efficient Low Energy crashing/crushing plant with 50-800tphcrashing/crushing plant introduction

crashing/crushing plant is easy to install, debug and maintenance, the continuous improvement and refinement has made it the preferred jaw crusher among professionals and customers. Every feature of crashing/crushing plant has been carefully designed to provide superior quality and performance. It is widely used in fields of mining, metallurgical, construction, smelting, hydraulic and chemical industries, etc.

crashing/crushing plant Application:

crashing/crushing plant is often used for coarse and medium crushing operations. It is a high-end product among jaw crushers. It is your choice to efficiently crush hard and strong corrosive materials. crashing/crushing plant has become one of the most popular crushers in fields of highway, railways, airport runways, mining, building materials, silicates, metallurgy, chemical industrial raw materials, etc.

Features of crashing/crushing plant

1. World-level manufacturing technology is adopted, and high-end manufacturing material is used.

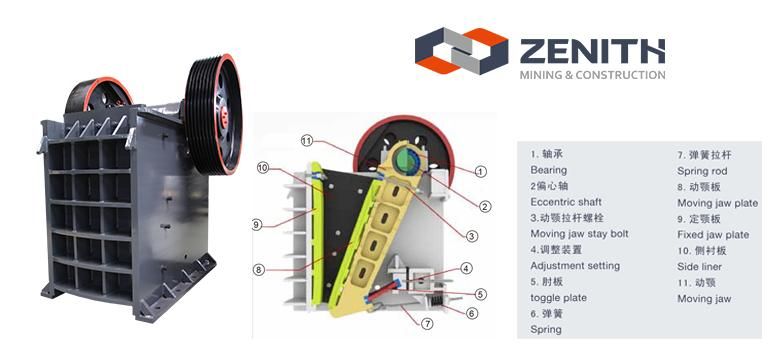

2. More advanced movable jaw assembly makes it more durable. The movable jaw assembly adopts high-quality steel casting, which is driven by two large-sized cast steel flywheels. In addition, the heavy eccentric shaft also adopts forging stock to ensure that crashing/crushing plant has extraordinary reliability.

3. Unitary cast steel structure is adopted by bearing pedestal. The unitary cast steel bearing pedestal makes it comprehensive fit with the crusher rack, which can greatly increase the radial strength of the bearing pedestal while split type bearing pedestal does not have these advantage

4. The strength of crashing/crushing plant is relative high by using finite element analysis technology.

5. The crushing chamber adopts symmetrical V-shaped structure to ensure that the actual width of the feeding mouth is in line with the nominal width of the feeding mouth.

6. The adjustment of the discharging mouth is quicker and more convenient. European type crashing/crushing plant is equipped with wedge discharging mouth adjustment device so that the adjustment of the discharging mouth is simpler, safer and quicker than that of traditional gasket adjustment.

7. The selected bearing has bigger specifications and higher carrying capacity. All the crashing/crushing plant are equipped with eccentric shaft bearing bigger and more durable than the crushers with the same specifications. The bearing greatly extends its service life with high carrying capacity and effective labyrinth sealing.

8. The latest tooth back plate is adopted to increase effective length of the jaw plate and output of crashing/crushing plant

crashing/crushing plant Working principle:

The motor drives belt and pulley wheel, making the movable jaw upside and down through the eccentric shaft. When the movable jaw pushes the movable jaw plate close to the fixed jaw plate, materials are crushed or chipped. When movable jaw and its plate get back under the action of eccentric shaft and spring, materials have been crushed are dropped out of the discharge opening. With the continuous rotation of the motor, the movable jaw cyclically crush and discharge materials, realizing mass production.

crashing/crushing plant specifications:

| Model | Feeder Opening (mm) | Setting Adjustment Range (mm) | Max. Feeding Size (mm) | Capacity (t/h) | Motor Power (KW) | Weight (t) | Overall Dimension (mm) |

| PE500x750 | 500x750 | 50-100 | 425 | 40-110 | 45-55 | 12 | 2035x1921x2000 |

| PE600x900 | 600x900 | 65-160 | 480 | 90-180 | 55-75 | 17 | 2290x2206x2370 |

| PE750x1060 | 750x1060 | 80-140 | 630 | 110-320 | 90-110 | 29 | 2655× 2302× 3110 |

| PE900x1200 | 900x1200 | 95-165 | 750 | 220-450 | 110-132 | 52 | 3200× 3050× 2950 |

| PE1000x1200 | 1000x1200 | 195-265 | 850 | 315-550 | 110-132 | 57 | 3800× 3166× 3045 |

| PE1200x1500 | 1200x1500 | 150-300 | 950 | 400-850 | 220 | 82.5 | 4200× 3750× 3820 |