Jaw Crusher, Stone Crusher, Rock Crusher

Shanghai Zenith Mineral Co., Ltd.- Motor Type:AC Motor

- Type:Jaw Crusher

- Motor Power:37kw

- Application:Mine

- Materials:Limestone

- Outlet Size:Various According to Different Model

Base Info

- Model NO.:PEW250x1200, PEW400x600, PEW760, PEW860

- Inlet Size:Various According to Different Model

- Condition:New

- Spare Parts Supply:for Whole Year

- Test&Installation:Engineer Assigned

- After-Sale Service:for Whole Using Life

- Export Markets:Global

- Transport Package:Container, Nude Packs, in Bulk

- Specification:ISO9001: 2000

- Trademark:Zenith

- Origin:China

- HS Code:8474209000

- Production Capacity:80sets,Month

Description

Basic Info.

Model NO. PEW250x1200, PEW400x600, PEW760, PEW860 Inlet Size Various According to Different Model Condition New Spare Parts Supply for Whole Year Test&Installation Engineer Assigned After-Sale Service for Whole Using Life Export Markets Global Transport Package Container, Nude Packs, in Bulk Specification ISO9001: 2000 Trademark Zenith Origin China HS Code 8474209000 Production Capacity 80sets/MonthProduct Description

Jaw Crusher, Stone Crusher, Rock Crusher

Introduction of Jaw Crusher, Stone Crusher, Rock Crusher

Based on years' experience and technology development, zenith Jaw Crusher, Stone Crusher, Rock Crusher are of 6 different models, which can meet most crushing requirements in primary and secondary crushing. Flexible discharge opening setting of Jaw Crusher, Stone Crusher, Rock Crusher allows perfect match with relative equipments. Zenith Jaw Crusher, Stone Crusher, Rock Crusher is easy to install, operate and maintain. As per feedback, our experts will make continuous improvements on our products to meet customers' changing needs. It is widely used in fields of mining, metallurgy, construction, smelting, hydropower and chemical industries etc.

Jaw Crusher, Stone Crusher, Rock Crusher Features

1. The application of world-class manufacturing processes and high-tech materials.

2. Integrated steel structures are used for the base of bearing;

3. The broken cavity using "V"-shaped structure, so that the actual width of feed is same as nominal width;

4. The broken cavity is deep and without dead zone, increased capacity and output feed;

5. Lubrication system is safe and reliable, convenient of replace parts, easy to maintenance;

6. The outlet employs pad-style adjustment devices, convenient and reliable, and increase the flexibility of the equipment;

7. Low noise, less dust;

Working principle of Jaw Crusher, Stone Crusher, Rock Crusher:

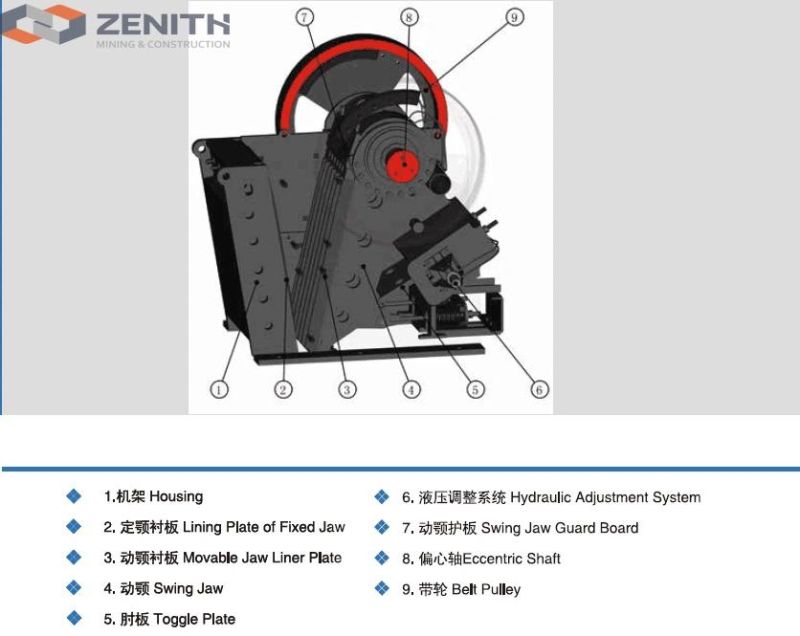

Jaw Crusher, Stone Crusher, Rock Crusher mainly consists of frame, eccentric shaft, jaw plate, connecting bar, adjustment part and spring.

The movable jaw goes upward and downward through eccentric shaft when belt and belt wheel are driven by the motor. The angle between movable jaw and bracket turns big when the movable jaw goes upward, which pushes the movable jaw plate to come closely to fixed jaw plate. At the same time, materials are crushed with the movement of the movable jaw.

When the movable jaw goes downward, the angle between movable jaw and bracket turns small. Under the force of spring and connecting bars, the movable jaw plate leaves fixed jaw plate, and the crushed materials with qualified size are discharged from the crushing cavity. With the continuous rotation of the motor, the movable Jaw Crusher, Stone Crusher, Rock Crusher and discharges materials, which, in turn, realizes the goal of mass production.

Jaw Crusher, Stone Crusher, Rock Crusher application:

Jaw Crusher, Stone Crusher, Rock Crusher is widely used in mine ore crushing, recycling of construction waste, construction aggregate, highway, railway, bridge and the production of construction industry.

Suitable Materials: It is widely used in all kinds of hardness of rock materials and ore crushing, such as granite, diabase, basalt, shale, sandstone, quartz stone, gravel, limestone, iron ore, copper ore, manganese ore, coal, nonferrous metal ore, stone etc.

Jaw Crusher, Stone Crusher, Rock Crusher technical data:

| Model | Feeder Opening (mm) | Setting Adjustment Range (mm) | Max. Feeding Size (mm) | Capacity (t/h) | Motor Power (KW) | Weight (t) | Overall Dimension (mm) |

| PE500x750 | 500x750 | 50-100 | 425 | 40-110 | 45-55 | 12 | 2035x1921x2000 |

| PE600x900 | 600x900 | 65-160 | 480 | 90-180 | 55-75 | 17 | 2290x2206x2370 |

| PE750x1060 | 750x1060 | 80-140 | 630 | 110-320 | 90-110 | 29 | 2655× 2302× 3110 |

| PE900x1200 | 900x1200 | 95-165 | 750 | 220-450 | 110-132 | 52 | 3200× 3050× 2950 |

| PE1000x1200 | 1000x1200 | 195-265 | 850 | 315-550 | 110-132 | 57 | 3800× 3166× 3045 |

| PE1200x1500 | 1200x1500 | 150-300 | 950 | 400-850 | 220 | 82.5 | 4200× 3750× 3820 |