Stlb60 / Stlb80 / Stlb30 Knelson Gravity Centrifugal Gold Concentrator

Ganzhou Gelin Mining Machinery Co., Ltd.- Voltage:380V

- Weight:<1T

Base Info

- Model NO.:STLB60 concentrator

- Certification:ISO9001:2008, CE

- Warranty:2 Years

- Condition:New

- Usage:Gold Diamond Tin Mining

- Capacity:1~100tons Per Hour

- Feeding Density:30%~50%

- Installation:Easy to Install

- Delivery Time:in Stock

- Transport Package:Export Packing Standard

- Specification:STLB80

- Trademark:GELIN

- Origin:China

- Production Capacity:1200sets Per Month

- Package size per unit product:40.00cm * 40.00cm * 60.00cm

- Gross weight per unit product:450.000kg

Description

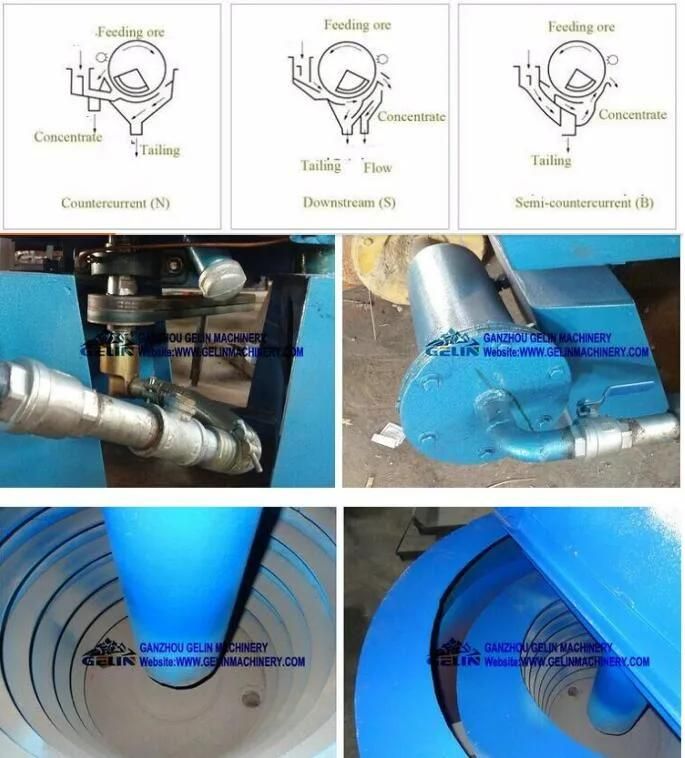

The Gold Concentration Separator, which is also called centrifugal concentrator is usually used for roughing separation during the gold separation flowchart to recover most of the useful minerals and get rid of most of the barren rocks.

2.Structure

The following drawing shows the structure of the Gold Concentration Separator:

3. Application:

4. Features:

2) High efficiency: STLB60 Gold Concentration Separator has a capacity of 15-30TPH, and STLB100 Gold Concentration Separator has a capacity of 60-100TPH. Only one machine could give you such a high capacity and high recovery rate. It's the most efficient concentration equipment in our factory.

3) Easy to install: only a small leveled place required. It's a complete machine, before starting it, only need to connect the fluidization water and power.

4) Easy to adjust: there are only 2 factors that will affect the recovery result, they are water pressure and feeding size. By giving proper water pressure and feeding size, you could get the best recovery effect.

Easy to operate: after finishing the water pressure and feeding size adjust, what U have to do is to fetch the concentrates every 2-4 hours. (Depending on the grade of the mine)

5) No pollution: this machine only consumes water and electric power, and exhaust tailings and water. Low noise, no chemical agent involved.

6) Reliable: this Gold Concentration Separator gets a simple & tough structure, the main body is made by strong steel, and the concentrate cone is made by stainless steel. And the bearing is greased to keep it running well.

5. Working Principle:

6.Technical Data Vein gold 1-3 Hours Placer gold " 2-6 Hours

Outside dia(mm) 1) Based on clients' request and budget, GELIN experts will strictly make efficient, reliable solutions accordingly; 2) Mine sample testing is available, we welcome the customer send the sample to you for testing by courier, or, the customer take the sample to our factory for testing; 3) Design and provide the complete processing flowchart; 4) Design & manufacturer products according to clients' demands. 1). Pre-check and test the products before delivery; 6). Provide technical exchanging & spare parts for life-long term 1) Starting by running the mineral beneficiation experiment. To provide our clients with the best solution accordingly; 2) Besides supply the flowchart design & equipment, we also provide the infrastructure design; Electrical & pipeline system design, etc. To help our clients complete the design of the whole plant; 3) After the installation, debugging of the equipment, the official production will also be guiding by our experienced engineers on site, to guarantee the output minerals perfectly meet your demands A:1). What type is the mining? Is it rock stone? or it is sand? A: Yes, we can run the ore-dressing experiments for our customers. After the test, we will based on the results to give you the reasonable flowchart, suitable solution and equipments selection. etc. A: The warranty period of Gelin equipments is one year. And of course we will supply the spare parts for you for life-long time at lowest cost. A: Yes, we can help you combine a complete mineral processing line. and give you related professional advices as long as you need.1500 1200 900 600 400 pitch(mm) 540,720 900,720,540 675,540,405 450,360,270 240,180 Pitch Dia Ratio 0.75,0.6,0.45 0.75,0.6,0.45 0.75,0.6,0.45 0.75,0.6,0.45 0.6,0.45 Lateral slope 9° 9° 9° 9° 9° Maximum starts per column 4-2 4-2 4-2 3-2 2-1 Max Feeding Size(mm) 3 3 3 3 3 Feeding Density(%) 25-55 25-55 25-55 25-55 25-55 Capacity(T/H) 8-6 4-6 2-3 0.8-1.2 0.15-0.2 External

SizeLength(mm) 1560 1360 1060 700 460 Width(mm) 1560 1360 1060 700 460 Height(mm) 5230 5230 4000 2600 1500 Weight (Kg) 800 600 400 150 50

ChamberMaximum

Feeding

size(mm)Water

added

m3/tPressure

of water

MpaCapacity

t/hMotor

power

kwDimension

mmWeight

kgshape area(m2) JT0.57-1 Ladder 0.57 6 1-3 >=0.5 1-2.5 1.5 1550x780x1530 610 JT1-1 Ladder 1.04 10 1-3 2-4 2.2 2270x1110x1890 900 JT1.5-2 Rect 1.53 10 1-2 3-8 3 3200x1550x2050 1520 JT2-2 Rect 2.28 10 1-3 4-8 3 3225x1550x2050 1640 JT3-1 Ladder 3.3 10 1-3 6-10 5.5 3180x2000x2600 3260 JT4-2 Rect 4.33 30 1-3 10-15 7.5 3600x1850x2600 4600 JT5-2 Ladder 4.86 10 1-3 10-15 7.5 3600x2000x2600 4500 JT1.5-2S Rect 1.53 30 1-3 3-8 1.5x2 3200x1550x2050 1590 JT2-2S Rect 2.28 30 1-3 4-8 3x2 3225x1550x2050 1700 JT3-2S Rect 3 30 1-3 6-15 5.5x2 3560x2030x2600 3260 JT4-2S Rect 4.33 30 1-3 10-20 4x2 3600x1850x2600 4660 JT5-2S Ladder 4.86 30 1-3 10-20 5.5x2 3600x2000x2600 4700 JT6-3S Rect 6 30 1-3 15-30 7.5x2 4600x2000x2600 5900

6). Hydraulic Radial Jig

Descriptions

Hydraulic radial jig has been widely used as roughing separation equipment to select ore such as alluvial gold, tin, diamond, tungsten, manganese and hematite.

Hydraulic radial jig is developed from circular jig. It's composed of two parts: drive and tank. The drive is mechanical hydraulic type, the power is provided by motor through the transmission mechanism let the output shaft of the gear reducer drives the cam rotation, the cam pushes the piston of each master cylinder make periodic reciprocating motion, which converts electrical energy into mechanical energy and then into hydraulic energy. Through hydraulic pipes and all kinds of valves let the moving cylinder drives the cone of jig up and down fluctuation.

Hydraulic radial jig adopts electromagnetic speed regulating asynchronous motor to realize the frequency adjustment, it's a step-less adjustment and the adjustable range of jig frequency is 0-90 times per minute.

Hydraulic radial jig has many advantages compared with the various jig machines: Big jigging area, big capacity; because the jig tank is fan-shaped, it is advantageous to recover fine particle materials; Compact structure, central feeding and small distribution space, suitable for use on dredger; Because of the hydraulic drive, the transmission mechanism is simplified and saving power. The total power of the same process capacity is only 11.6 Kw, saving about 55% power than the conventional jig machine in the same concentration area. The pulsation curve is approximation saw-tooth curve, not only conducive to recover fine heavy minerals, also saving a large number of make-up water, the make-up water is about a quarter of the ordinary jig.

Advantages and CharacteristicsFeeding size

(mm)<25 Make-up water

(m3/t)1-3m3/ton of ore Make-up water pressure

(MPa)≥0.10 Capacity

(t/h)50-75 66-100 78-125 100-150 116-175 132-197 150-200 166-245 182-270 200-300 Driving motor

(Kw)5.5 7.5 7.5 7.5 11 11 11 15 15 22 hydraulic power unit

(Kw)0.55 Weight

(kg)6000 8000 10000 12500 14200 15800 17500 18000 19200 21000

Ganzhou Gelin Mining Machinery Co., Ltd is an expert manufacturer of mining machines in China. Our company is located in Guzhang Industrial Zone, Shicheng county, Jiangxi province, covering an area of over 30000 square meters, having more than 30 sets of heavy processing equipment and with an annual outpurt of more than 2000 sets of mining machinery. ---Experienced Mining Machinery Manufacturer---

Our distinctive prodcts include shaking table, Jig, Spriral separator, Gold concentrator, Ball mill, Jaw crusher, flotation, magnetic separator, feeder, classifier, ore washing machine and lab equipment ect. Our machines are popular in separating GOLD, copper, manganes, chrome, tungsten, tin, nickel, iron, titanium, lead, zinc, tantalum and some non-ferrous metals like quart, zircon, barite,ect.

--- PRE-SALE SERVICE ------ AFTER-SALE SERVICE ---

2). Deliver the whole plant design for our clients which including infrastructure, electrical system and pipeline system design;

3). Trace the status of the shipping until the products received;

4). Prepare required documents to let clients pass custom clearance;

5). Dispatch experts to carry out below service on site:

A) Installation & debug of the machinery

B) Train the first-line operators & technical personnel

C) Carry out any other service clients may need--- ONE STOP SOLUTION ---

9. FAQ:Q: What Information should customers give to us in order to let we provide you with efficient & suitable quotation and assistance.

2). If rock stone,What is the general particle size(mm) of the raw ore?

3). What is the handling capacity(tons per hour) you plan to work with?

4).What is the elements of the raw ore? How much percent % of each minerals?Q: Can we send the mineral samples to your company, let your company run the ore-dressing experiments test for us?

Q: How long is the warrenty of your equipments? Does your company supply the spare parts?

Q: If i need the complete mineral processing line. is Gelin able to help us build it?

There is a rich experience engineer team of us. we had already build many mining projects in China & Overseas. You can believe our quality and service.

10. Welcome To Visit Our Factory!

Till now, our machines are exported to over 60 countries, such as United States, Canada, Peru, Brazil, Russia, England, Spain, Sudan, Morocco, Cote d'lvorie, Ghana, Congo, Mali, Zimbabwe, South Africa, Mozambique, Cameroon, Tanzania, Kenya, Angolia, India, Malaysia, Philippines, Indonesia, Australia, New Zealand, Mongolia, Myanmar etc...

Looking Forward To Your Joinning!!!