900 X 1200 Small Grinding Ball Mill

Jiangxi Hengchang Mining Machinery Manufacturing Co., Ltd.- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:80kw

- Rotationl Speed:30.7r,Min

- Application:Mine

- Materials:High Manganese Steel

Base Info

- Model NO.:900*1200 Ball Mill

- Condition:New

- Product Name:Ball Mill

- Usage:Grinding All Kinds of Rock Minerals

- Model:GM0912 Ball Mill

- Capacity:0.3-0.9tph

- Power:11 Kw

- Liners Materials:High Manganese Steel

- Feeding Size:25mm

- Loading Steel Balls:1.1tons

- Oversize:3843*1850*1400mm

- Ball Mill Weight:4210kg

- Transport Package:by FCL or LCL

- Specification:Standard

- Trademark:Hengchang Ball Mill

- Origin:China

- HS Code:8474202000

- Production Capacity:20 Sets,Month

Description

Basic Info.

Model NO. 900*1200 Ball Mill Condition New Product Name Ball Mill Usage Grinding All Kinds of Rock Minerals Model GM0912 Ball Mill Capacity 0.3-0.9tph Power 11 Kw Liners Materials High Manganese Steel Feeding Size 25mm Loading Steel Balls 1.1tons Oversize 3843*1850*1400mm Ball Mill Weight 4210kg Transport Package by FCL or LCL Specification Standard Trademark Hengchang Ball Mill Origin China HS Code 8474202000 Production Capacity 20 Sets/MonthProduct Description

900 X 1200 Small Grinding Ball Mill

900 X 1200 Small Grinding Ball MillHengchang Ball Mill can satisfy different requirement, and have good features such as low consumption, high capacity per hour, no pollution to the enviroment around, easy to be repaired.

Ball Mill is a key equipment to grind the crushed materials, and the Ball Mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc. And the ball mill can grind various ores and other materials with dry type and wet type. There are two kinds of ball mill, grate type and overfall type due to different ways of discharging material.

Ball Mill is a key equipment to grind the crushed materials, and the Ball Mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc. And the ball mill can grind various ores and other materials with dry type and wet type. There are two kinds of ball mill, grate type and overfall type due to different ways of discharging material. Working Principle of Ball Mill

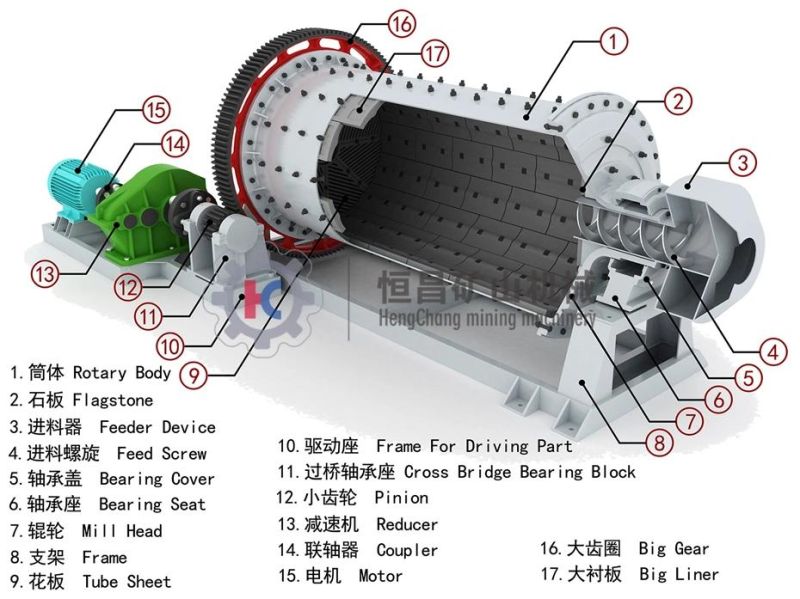

The Ball Mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Features of Ball Mill

1. Wide usage, simple structure, convenient maintenance;

2. Big capacity, continuous working;

3. Body liners and grinding medium could be made of various of materials, good corrosion resistance;

4. Easy installation, adjustment, and operation.

Parameters of Ball Mill| Model | Cylinder rotary speed(r/min) | Loading ball weight(t) | Input size(mm) | Discharge size(mm) | Capacity(t/h) | Motor power (kw) | Weight (t) |

| Ø900×1800 | 39 | 1.5 | ≤20 | 0.075-0.89 | 0.8-2 | 18.5 | 4.6 |

| Ø900×3000 | 39 | 2.7 | ≤20 | 0.075-0.89 | 1~4 | 22 | 5.6 |

| Ø1200×4500 | 32 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| Ø1500×3000 | 27 | 7.5 | ≤25 | 0.074-0.4 | 2~5 | 75 | 15.6 |

| Ø1500×5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

| Ø1830×3000 | 25 | 11 | ≤25 | 0.074-0.4 | 4~10 | 130 | 28 |

| Ø1830×6400 | 24 | 21 | ≤25 | 0.074-0.4 | 7~16 | 210 | 34 |

| Ø2100×3600 | 23 | 19 | ≤25 | 0.074-0.4 | 10-36 | 210 | 46 |

| Ø2200×4500 | 21 | 27 | ≤25 | 0.074-0.4 | 12~23 | 280 | 48.5 |

| Ø2200×6500 | 21 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 | 52.8 |

| Ø2200×7000 | 21 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 54 |

| Ø2200×7500 | 21 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 56 |

| Ø2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 18-45 | 320 | 65 |

| Ø2700×3600 | 21 | 39 | ≤25 | 0.074-0.4 | 19-75 | 400 | 83 |

| Ø2700×4500 | 20 | 48 | ≤25 | 0.074-0.4 | 22-85 | 430 | 89 |

| Ø3200×4500 | 18 | 65 | ≤25 | 0.074-0.4 | 29-140 | 800 | 137 |

| Ø3200×5400 | 18 | 81.6 | ≤25 | 0.074-0.4 | 30-180 | 800-1000 | 146 |

| Ø3600×4500 | 17 | 88 | ≤25 | 0.074-0.4 | 35-210 | 1000 | 190 |

| Ø3600×8500 | 17 | 144 | ≤25 | 0.074-0.4 | 45-260 | 1800 | 260 |

About US

Jiangxi Hengchang Mining Machinery Manufacturing Co., Ltd. is located in No.3 Chuangye Road. Guzhang In dustrial Park. Shicheng County. Ganzhou City. Jiangxi Province. China.Our company is engaged in the mineral processing equipment research, development, design and production for many years history, has accumulated rich experience in design and production. Enterprise in mineral processing equipment industry has had a positive effect, set up the good reputation. And mainly the manufacture of the products like as Shaking table. Flotation equipment. Crushing equipment. Magnetic separator. Screening equipment. Classifying equipment. Agitation tank, Feeding equipment. Gravity separation equipment. Wet separation equipment. Spiral chute. Saw-tooth wave jig and Diaphragm Jig. Grinding equipment. Ball mill. Slurry pump. Centrifugal pump, Conveying equipment.

We manufacture various types of mineral processing machinery and equipment according to our customers' requirements. Our products are widely used for sorting gold, silver, copper, iron, tungsten,lead. zinc. tin. molybdenum, nickel, tantalum, niobium, manganese ore, coal, monazite, rutile,diamonds, other precious metals and precious metals mine, and for the flotation colored, black metal,precious metals and other minerals. And we have export qualifications, our products sell well all over the world for several years, especially exported to Brazil. India. Indonesia.South Africa. Somalia, Philippines. Malaysia. Sudan, Nigeria. Russia, Ghana. Kazakhstan Kyrgyzstan.Cambodia,Vietnam,Korea,Mongolia and other countries.