Gold Separator Machine Gold Centrifugal Concentrator

Jiangxi Gandong Mining Equipment Machinery Manufacturer- Type:Gravity Separator

- Voltage:380V

- Weight:5T

- Material:Casting Steel

- Material Feature:Durable

- Certification:ISO9001:2008, CE

Base Info

- Model NO.:STLB100,80,60,30,20

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Blue

- Customized:Customized

- Condition:New

- After-sales Service:One Year Guarantee

- Application:Gold Plant

- Feeding Density:0-50%

- Feeding Size:0-3mm

- Concentrate Cleaning up Cycle:1-3hours

- Concentrate Weight:2-70kg

- Power:0.75-18.5kw

- Which Method Type:Gravity Separator

- Whole Line Machine:Supply

- Sample Test:Supply

- Visit Factory:Supply

- Transport Package:Nude in Container

- Specification:STLB20,30,60,80,100

- Trademark:Gandong

- Origin:Jiangxi Province, China

- HS Code:84741000

- Production Capacity:30set,Month

Description

Applications:

Alluvial gold plant in Zambia

Alluvial gold plant in Africa

Sticky clay gold plant

Sticky clay gold plant About us:

FAQ:

FAQ:Q:If the concentrate can automatic discharge.

A;Yes,centrifugal concentrator match with variable frequency motor,and inverter.all step just need press button on control cabinet.

Q: If i need the complete mineral processing line. Can you help us build it?

A: Yes, we can help you combine a complete mineral processing line. and give you related professional advice as long as you need. There is a rich experienced engineers team of us, these 12 engineers always fly out of China to install, debugging our equipments on site and trainning the buyer's staff.

Q: How long is the guarantee of your equipments? Does your company supply the spare parts?

A: The warranty period of is one year, if break during this guarantee period, we need to replace new one for you AT NO COST. And of course we will supply the spare parts for you for life-long time at lowest cost.

Q: Do you cut the steel plate by hand?

A: No, we use the plasma cutting machine to cut all materials which is controlled by computer. It's very accurate.

--- PRE-SALE SERVICE

--- 1.Based on clients' request and budget, our experts will strictly make efficient, reliable solutions accordingly;

2.Mine sample testing is available, we welcome the customer send the sample to us for testing by courier, or, the customer take the sample to our factory for testing;

3. Design and provide the complete processing flowchart;

4. Design & manufacturer products according to clients' demands.

--- AFTER-SALE SERVICE -

-- 1.Pre-check and test the products before delivery;

2.Deliver the whole plant design for our clients which including infrastructure, electrical system and pipeline system design;

3.Trace the status of the shipping until the products received;

4.Prepare required documents to let clients pass custom clearance;

5.Dispatch experts to carry out below service on site:

1) Installation & debug of the machinery

2) Train the first-line operators & technical personnel

3) Carry out any other service clients may need

4. Provide technical exchanging & spare parts for life-long term

--- ONE STOP SOLUTION

-- 1.Starting by running the mineral beneficiation experiment. To provide our clients with the best solution accordingly;

2.Besides supply the flowchart design & equipment, we also provide the infrastructure design; Electrical & pipeline system design, etc. To help our clients complete the design of the whole plant;

3.After the installation, debugging of the equipment, the official production will also be guiding by our experienced engineers on site, to guarantee the output minerals perfectly meet your demands.

Why Choose Us?

We are manufacturer, not trade company.

-Quality: Guarantee

-Delivery: On Time

-Communication: In Time

-After-Sales Service: Excellent

-Engineer Team: Professional & more than 20 years experience on site

-Price: Competitive

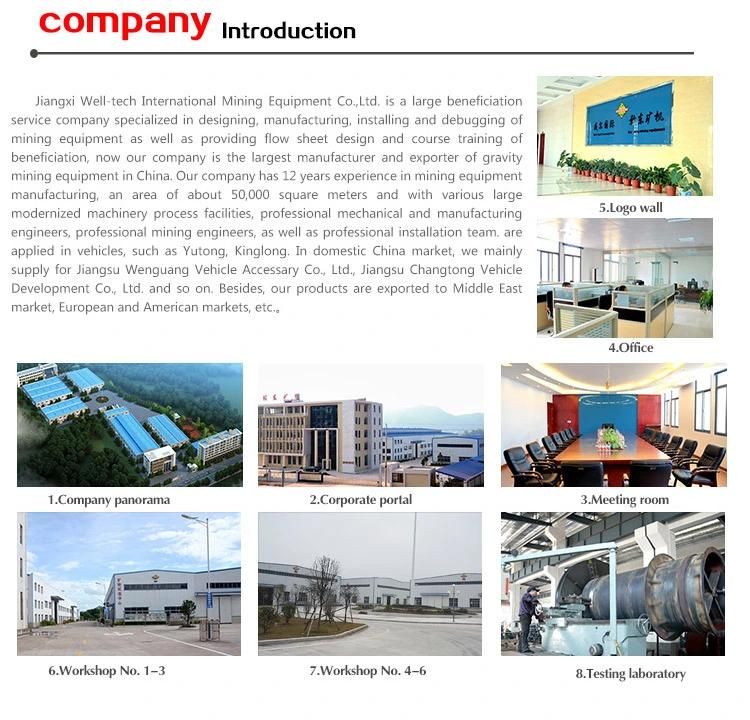

Welcome you visit our factory when you are free, we will arrange our driver to pick you up from Airport for free and book hotel for you in advance. Well-Tech International Mining Equipment Co.,Ltd. Has more than 200 workers and 7pcs big workshop which takes more than 30000m2 floor. One office building and one ancillary building, factory environment is very good. We have tennis court, basketball court, table tennis course etc entertainment .

More details,please don't hesitate to Contact us,please send us inquiry as below,we will reply you within 24hours.Thanks for your Attention. Mily