Hard Rock High Air Pressure DTH Hammer for Mining Drilling and Water Well Atlas Copco

TAIZHOU CITY KAIYU METALLURGY MACHINES & TOOLS CO., LTD.- Certification:ISO9001:2015, SGS

- Standard:GB

- Surface Treatment:Polishing

- Manufacturing Process:Forging

- Material:Carbon Steel

- Power Type:Pneumatic

Base Info

- Model NO.:DTH Hammer

- Condition:New

- Color:Golden, Steel

- Process:Heat Treatmen

- Transport Package:Wooden Case

- Specification:115mm

- Trademark:Kaiyu

- Origin:Taizhou, Zhejiang

- HS Code:8207199000

- Production Capacity:5000 PCS Per Month

Description

Basic Info.

Model NO. DTH Hammer Condition New Color Golden, Steel Process Heat Treatmen Transport Package Wooden Case Specification 115mm Trademark Kaiyu Origin Taizhou, Zhejiang HS Code 8207199000 Production Capacity 5000 PCS Per MonthProduct Description

Product Information

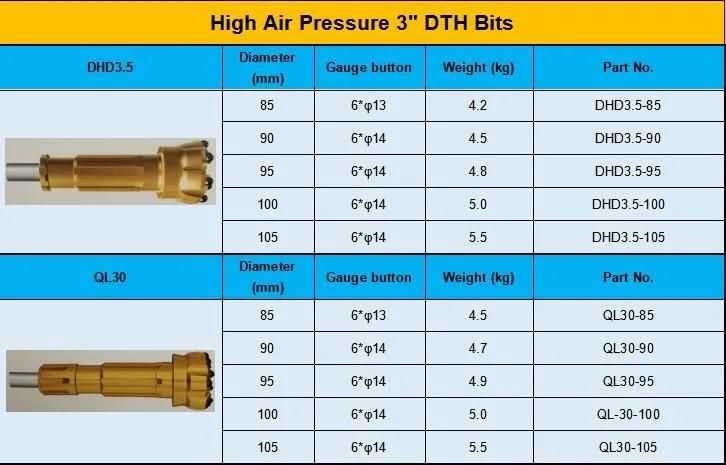

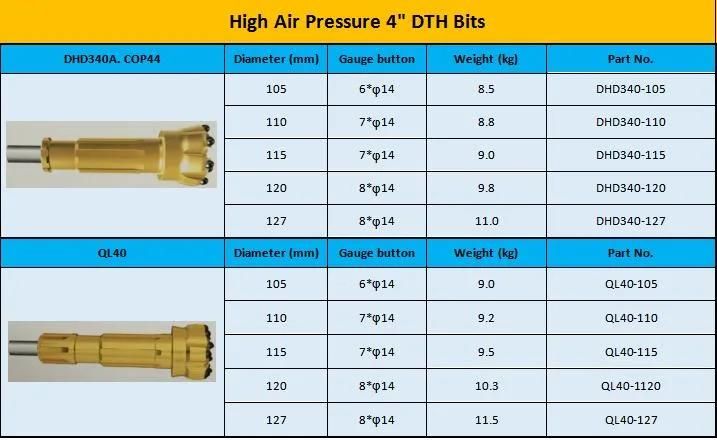

Product Information-Name: Ballistic DTH Drill Bits Used for High Air Pressure DTH Hammers

-Item Number: DTH BUTTON BITS

-Brand Name: KAIYU

-Diameter: 90/95/100/105/110/115/120/127/130/135/140/146/152/165/171/190/203/216/254/305/330mm

-Material: Carbide

- Processing Type: Forging

-Color: Golden, Red, Blue etc

-Packaging: Wooden Case

-Delivery: 15-30days

-Certification: ISO9001

-Place of Origin: Taizhou, Zhejiang,China (Mainland)

-Use: Water well,quarry,open pit and underground construction

-Advantage: High performance cost ratio

.

Product Description

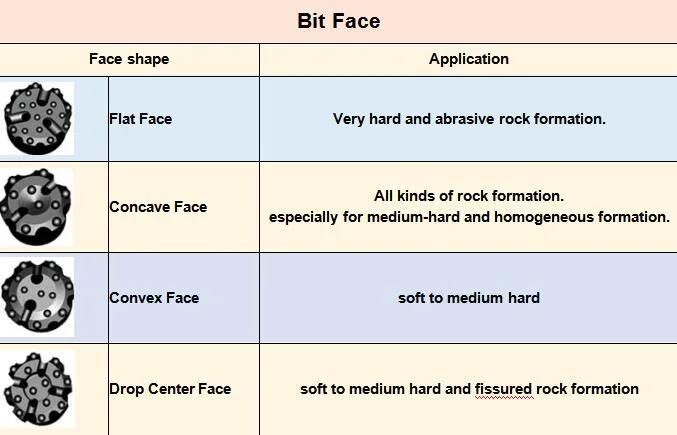

DTH bits are used for blast hole drilling. It Works with DTH hammer, mainly applied in mining, tunneling, marble quarrying or well drilling, construction and civil engineering projects.

Our bits are interchangeable with Atlas Copco's COP32 34 44 54 64 84, Ingersoll-Rand 's DHD3.5, DHD 340A, DHD350R, DHD 360, DHD380, QL40, QL50 , QL60, QL80. etc.

Package

plywood case, paper box+foam

Shipment and Payment

By sea, by air, and by road; T/T (Telegraphic Transfer) or Western Union or L/C at sight

Why do you choose KAIYU high air pressure DTH bits?

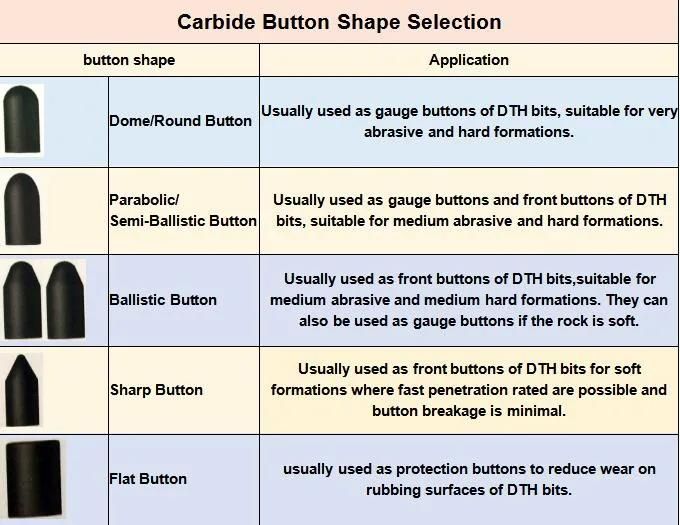

1. Mature heat treatment technology ensure high quality of bits

2. Accurate dimension of shanks perfectly matches DTH hammers

3. work reliable and very cost-effective

4. High grade tungsten carbide inserts

5. Bit bodies manufactured from high grade steel and processed using state-of-the-art CNC machinery and heat treatment.

6. Our sales team will response for your question within 24 hours (Holidays Excluded)

7.Technical Support will be available in any time

8.Free replacement will provide once the failure confirmed caused by our product quality.